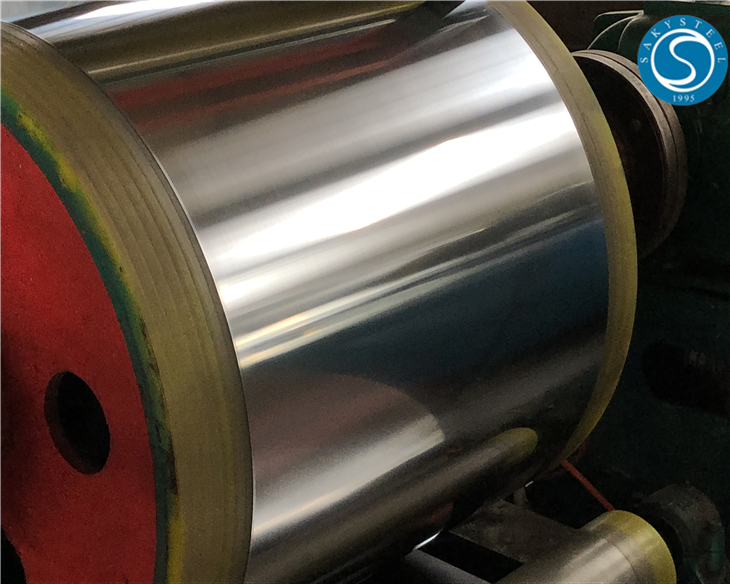

Arddangosfa Gwasanaeth Un Stop Coiliau Dur Di-staen:

VIDEO

430 dalen ddur di-staenCyfansoddiad cemegol a phriodweddau mecanyddol:

C% Si% Mn% P% S% Cr% Ni% N% Mo% ti% 0.12 1.00 1.00 0. 040 0.030 16.0-18.0 0.75 - - -

T*S Y*S Caledwch Elongation (Mpa) (Mpa) HRB HB (%) 520 205 - - 40

Rholio Oer 430 dalen ddur di-staen:

1. Gradd: 200 & 300 gyfres 200 o gyfresi: 201,202, J4 300 o gyfresi: 301, 304, 304L, 321, 316L, 309, 310S 2. Safon: JIS, ASTM, AISI, GB, DIN, EN, rydym fel arfer yn defnyddio ASTM a GB Safonol 3. Trwch: 0.14mm-3.0mm 4. Lled: yn ôl yr angen 5. Arwyneb: 2B wedi'i orffen, BA wedi'i orffen 6. Caledwch: meddal, 1/4H, 1/2H, FH 7. Trwch Goddefgarwch: +/-0.02mm 8. Goddefgarwch Lled: +/- 10mm (ymyl y felin)

Mwy o raddau o daflen 430 ss:

Math Gradd Gradd Cydran Cemegol % Dur di-staen austenitig C Cr Ni Mn 201 1Cr17Mn6Ni5N 0.15 16.00-18.00 3.50-5.50 5.50-7.50 201L 03Cr17Mn6Ni5N 0.030 16.00-18.00 3.50-5.50 5.50-7.50 202 1Cr18Mn8Ni5N 0.15 17.00-19.00 4.00-6.00 7.50-10.00 204 03Cr16Mn8Ni2N 0.030 15.00-17.00 1.50-3.50 7.00-9.00 1Cr18Mn10Ni5Mo3N 0.10 17.00-19.00 4.00-6.00 8.50-12.00 2Cr13Mn9Ni4 0.15-0.25 12.00-14.00 3.70-5.00 8.00-10.00 2Cr15Mn15Ni2N 0.15-0.25 14.00-16.00 1.50-3.00 14.00-16.00 1Cr18Mn10Ni5Mo3N 0.15 17.00-19.00 4.00-6.00 8.50-12.00 301 1Cr17Ni7 0.15 16.00-18.00 6.00-8.00 2.00 302 1Cr18Ni9 0.15 17.00-19.00 8.00-10.00 2.00 303 Y1Cr18Ni9 0.15 17.00-19.00 8.00-10.00 2.00 303se Y1Cr18Ni9Se 0.15 17.00-19.00 8.00-10.00 2.00 304 0Cr18Ni9 0.07 17.00-19.00 8.00-10.00 2.00 304L 00Cr19Ni10 0.030 18.00-20.00 8.00-10.00 2.00 304N1 0Cr19Ni9N 0.08 18.00-20.00 7.00-10.50 2.00 304N2 0Cr18Ni10NbN 0.08 18.00-20.00 7.50-10.50 2.00 304LN 00Cr18Ni10N 0.030 17.00-19.00 8.50-11.50 2.00 305 1Cr18Ni12 0.12 17.00-19.00 10.50-13.00 2.00 309S 0Cr23Ni13 0.08 22.00-24.00 12.00-15.00 2.00 310S 0Cr25Ni20 0.08 24.00-26.00 19.00-22.00 2.00 316 0Cr17Ni12Mo2 0.08 16.00-18.50 10.00-14.00 2.00 1Cr18Ni12Mo2Ti6) 0.12 16.00-19.00 11.00-14.00 2.00 0Cr18Ni12Mo2Ti 0.08 16.00-19.00 11.00-14.00 2.00 316L 00Cr17Ni14Mo2 0.030 16.00-18.00 12.00-15.00 2.00 316N 0Cr17Ni12Mo2N 0.08 16.00-18.00 10.00-14.00 2.00 316N 00Cr17Ni13Mo2N 0.030 16.00-18.50 10.50-14.50 2.00 316J1 0Cr18Ni12Mo2Cu2 0.08 17.00-19.00 10.00-14.50 2.00 316J1L 00Cr18Ni14Mo2Cu2 0.030 17.00-19.00 12.00-16.00 2.00 317 0Cr19Ni13Mo3 0.12 18.00-20.00 11.00-15.00 2.00 317L 00Cr19Ni13Mo3 0.08 18.00-20.00 11.00-15.00 2.00 1Cr18Ni12Mo3Ti6 0.12 16.00-19.00 11.00-14.00 2.00 0Cr18Ni12Mo3Ti 0.08 16.00-19.00 11.00-14.00 2.00 317J1 0Cr18Ni16Mo5 0. 040 16.00-19.00 15.00-17.00 2.00 321 1Cr18Ni9Ti6 0.12 17.00-19.00 8.00-11.00 2.00 0Cr18Ni10Ti 0.08 17.00-19.00 9.00-12.00 2.00 347 0Cr18Ni11Nb 0.08 17.00-19.00 9.00-13.00 2.00 XM7 0Cr18Ni9Cu3 0.08 17.00-19.00 8.50-10.50 2.00 XM15J1 0Cr18Ni13Si4 0.08 15.00-20.00 11.50-15.00 2.00

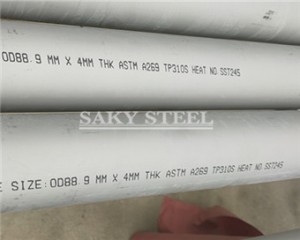

Pâr o: Pibellau Wedi'u Weldio Dur Di-staen Nesaf: Stribed Dur Di-staen