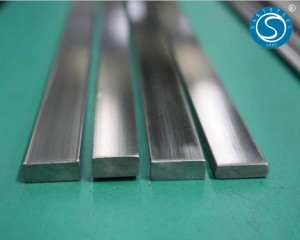

CCCXVI Steel Square Pipe / Tubing

Description:

TP316 Steel Square Tubing, SUS316, S31600, EN1.4401,X5CRNIMO,SS 316 corrosio resistens in ambitibus marinis et chemicis variis et corrosio resistentiae praestantissimae, pondus (Kg/Meter)=0.02513* crassum(mm)*(OD-crassum)(mm)

| C% | Si% | Mn% | P% | S% | Cr% | Ni% | N% | Mo% | Ti% |

| 0.08 | 0.75 | 2.0 | 0.041 | 0.03 | 16.0-18.0 | 10.0-14.0 | - | 2.0-3.0 | - |

| Specificationes 316 Steel Square Pipe: |

| Nomen | 316 Stainless Square Tubing | |||||

| Standard | GB/T14975, GB/T14976, GB13296-91, GB9948 , ASTM A312, ASTM A213; | |||||

| ASTM A269, ASTM A511, JIS349, DIN17456, ASTM A789, ASTM A790, DIN17456,DIN17458, EN10216-5, JIS3459, GOST 9941-81 | ||||||

| Materia Gradus | 304, 304L, 316, 316L, 321, 321H, 310S, 347H,309.317.0cr18N9,0Cr25Ni20; | |||||

| 00Cr19Ni10,08X18H10T,S31803,S31500,S32750 | ||||||

| Diameter exterior | 6mm ad 1219mm | |||||

| Crassitudo | 0.8mm – 40mm | |||||

| Magnitudo | OD (6-1219) mm x (0.9-40)mm x MAX 13000mm | |||||

| tolerantia | sub ASTM A312 A269 A213 standard | |||||

| sub ASTM A312 A269 A213 standard | ||||||

| sub ASTM A312 A269 A213 standard | ||||||

| Superficies | 180G, 320G Satin / Hairline. | |||||

| SALTATIO & ANNEALING | ||||||

| Applicationem | Liquidum et gasi onerariam, ornamentum, constructionem, apparatum medicinae, aviation | |||||

| PRAEFURNIUM calor-commutatori et aliis agris | ||||||

| Test | Adulatione Test, Hydrostatic Test, Intergranulare Test Corrosio, Test adulatione, Testis Eddy, etc. | |||||

| nativus | alias determinationes secundum clientium necessitates | |||||

| Tempus adferendi | ad ordinem quantitatis | |||||

| stipare | Plastica sacco fasciculo subtecto, casibus ligneis vel secundum petitionem clientium. | |||||

| Mechanica Property | Materia Item | 304 | 304L | 304 | 316L | Top Technology |

| Distrahentes fortitudo | 520 | 485 | 520 | 485 | ||

| Cedat imperium | 205 | 170 | 205 | 170 | ||

| Extensio | 35% | 35% | 35% | 35% | ||

| duritia (HV) | <90 | <90 | <90 | <90 | ||

| Plura singula de Steel Square Pipe: |

| Gradus | Chemical Compositio (%) | |||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | |

| 201 | 0.15 | 1.00 | 5.5~7.5 | 0.093 | 0.030 | 3.50~5.50 | 16.00~18.00 | |

| 301 | 0.15 | 1.00 | 2.00 | 0.041 | 0.030 | 6.00~8.00 | 16.00~18.00 | |

| 302 | 0.15 | 1.00 | 2.00 | 0.041 | 0.030 | 8.00~10.00 | 17.00~19.00 | |

| 304 | 0.08 | 1.00 | 2.00 | 0.041 | 0.030 | 8.00~10.50 | 18.00~20.00 | - |

| 304L | 0.030 | 1.00 | 2.00 | 0.041 | 0.030 | 9.00~13.50 | 18.00~20.00 | - |

| 316 | 0.041 | 1.00 | 2.00 | 0.041 | 0.030 | 10.00~14.00 | 10.00~18.00 | 2.00~3.00 |

| 316L | 0.030 | 1.00 | 2.00 | 0.041 | 0.030 | 12.00~15.00 | 16.00~18.00 | 2.00~3.00 |

| 430 | 0.12 | 0.75 | 1.00 | 0.041 | 0.030 | 0.60 | 16.00~18.00 | - |

| 430A | 0.06 | 0.50 | 0.50 | 0.030 | 0.50 | 0.25 | 14.00~17.00 | - |

| Materia | Austenite Steel: Rs-2,317L,904L,253Ma(S30815),254SMo(F44/S31254) |

| Biphase immaculata ferro F51(S31803),F53(S32750),F55(S32760),329(S32900),A4 | |

| Hastelloy C276, Hastelloy C4, Hastelloy C22.Hastelloy B, Hastelloy B-2 | |

| Nitronic50(S20910/XM-19), Nitronic60(S21800/Alloy218), Alloy20Cb-3, Alloy31(N08031/1.4562) | |

| Incoloy825, 309S, Inconel601,A286, Alloy59, 316Ti, SUS347, 17-4PH Nickle201… Ect. | |

| Monel400, Monel k500, Ninckel200, Nickel201(N02201) | |

| Inconel718 (N07718/GH4169), Inconelx-750(N07750/GH4145) | |

| Incoloy800H(NS112/N08810),Incoloy800HT(N08811),Incoloy800(NS111/N08800),Incoloy825(N08825/NS142), Incoloy901,Incoloy925(N09925),Incoloy926 | |

| 1J50,1J79,3J53,4J29(F15),4J36(Invar36) | |

| GH2132(incoloyA-286/S66286), GH3030, GH3128, BH4145(inconelx-750/N07750), GH4180(N07080/Nimonic80A) | |

| Logo | JYSS, etiam secundum huius requisita |

| MOQ | 1pcs saltem, etiam pro magnitudine et materia |

| Una stop emptio | adiuvamus te una terminatione emendarum, clavicularios, flanges, ac etiam organa fistularum in his exoticis materiis fabricare potuimus. |

| Altera Acceptae | Ita |

| Test libellum molendini | Ita |

| Inspectionis fama | Ita |

| Terminum solucionis | L/CT/T |

| Stipare singula | wodden causa vel ut per elit postulationem |

| emitur terris | Civitates Foederatae, Germania, Arabia, Arabia, Corea Meridionalis, etc |

| Productio Flow | Inspectio materiae rudis materiarum rudium secandi Calefaciens stamping- . |

| EXERCITATIO Machining Calefactio amet lavatio Non perniciosius examen | |

| Operis recognitionis |

commoda:

1. Involucrum causa lignea, quae vecturae marinae fortis et idonea est, methodus principalis nostra est ad fistulas colligendas.Et modus sarcinae oeconomicae qualis in fasciculis refertus est, etiam a quibusdam clientibus excipitur.

2. Tolerantia potestate utimur est D4/T4 (+/-0.1mm) tam intus quam extra Diametri et Wall Crassitudo, quae multo altior quam vexillum internationale ASTM, DIN.

3. Superficies superficies una est praecipuis commodis nostris: ut diversis requisitis pro superficiei conditione occurrant, habemus superficiem furnum et salsum, superficiem furnum, OD superficiem politam, OD & ID superficiem politam etc.

4. Ut interiorem organi superficiem puram servet et eam a debiliteat liberam, societas nostra technologiam unicam et specialem evolvit — Spongia lavatio cum alto pressura.8. Habemus post venditionem integram operam ad negotia in tempore tractanda. .