The quality 254SMO material always has a perfect standard value in its chemical composition, each component has its own function:

Nickel (Ni): Nickel can increase the strength of 254SMO steel while maintaining good plasticity and toughness. Nickel has high corrosion resistance to acids and alkalis, and has rust and heat resistance at high temperatures.

Molybdenum (Mo): Molybdenum can refine the grain of 254SMO steel, improve the hardenability and thermal strength, and maintain sufficient strength and creep resistance at high temperatures (long-term stress at high temperatures, deformation, creeping change).

Titanium (Ti): Titanium is a strong deoxidizer in 254SMO steel. It can make the internal structure of the steel dense, refine the grain force; reduce the aging sensitivity and cold brittleness. Improve welding performance. Addition of appropriate titanium to chromium 18 nickel 9 austenitic stainless steel prevents intergranular corrosion.

Chromium (Cr): Chromium can improve the corrosion resistance of steel and is therefore an important alloying element of 254SMO stainless steel and heat-resistant steel.

Copper (Cu): Copper can increase strength and toughness, especially at atmospheric corrosion. The disadvantage is that hot brittleness tends to occur during hot working and the plasticity of copper exceeds 0.5%. When the copper content is less than 0.50%, there is no effect on the solderability of the 254SMO material.

Based on the differences in the above main components, the following types of 254SMO nickel alloys can be used:

1. Nickel-copper (Ni-Cu) alloy, also known as Monel alloy (Monel alloy)

2. Nickel-chromium (Ni-Cr) alloy is a nickel-based heat-resistant alloy.

3. Ni-Mo alloy mainly refers to Hastelloy B series

4. Ni-Cr-Mo alloy mainly refers to Hastelloy C series

254SMO is used in various industrial equipment, its internal use of leaf springs, coil springs, sealing parts, automotive exhaust manifolds, catalytic converters, EGR coolers, turbochargers and other heat-resistant gaskets, aircraft Austenitic stainless steel plates are used for joint parts.

In particular, a part of applications for various industrial equipments, automobile exhaust gaskets, etc. used under high temperature uses NPF625 and NCF718 specified in JIS G 4902 (corrosion-resistant and heat-resistant superalloy plate) to contain mass percentages. It is more than 50% of expensive material of Ni. On the other hand, for materials such as precipitation-enhanced stainless steel such as SUH660 that uses intermetallic compounds of Ti and Al specified in JIS G 4312 (heat-resisting steel plate), the hardness of 254 SMO decreases greatly when used for a long time at high temperatures, and only The use up to about 500°C does not satisfy the characteristics required for the heat-resisting gaskets that have been promoted by the high temperature in recent years.

Brand: 254SMO

National standards: 254SMO/F44 (UNS S31254/W.Nr.1.4547)

Partners: Outokumpu, AVESTA, Hastelloy, SMC, ATI, Germany, ThyssenKrupp VDM, Mannex, Nickel, Sandvik, Sweden Japan Metallurgical, Nippon Steel and other famous brands

American brand:UNS S31254

Overview of 254SMo (S31254): A super austenitic stainless steel. Due to its high molybdenum content, it has extremely high resistance to pitting and crevice corrosion. 254SMo stainless steel was developed and developed for use in halide-containing environments such as seawater.

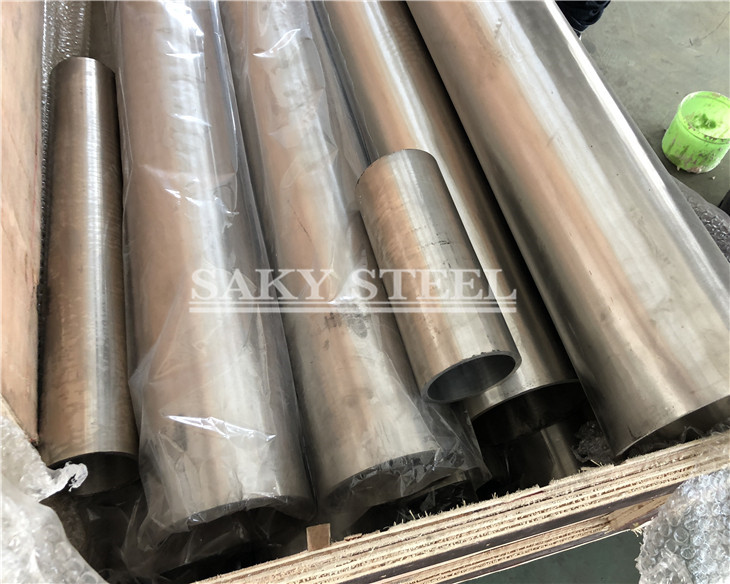

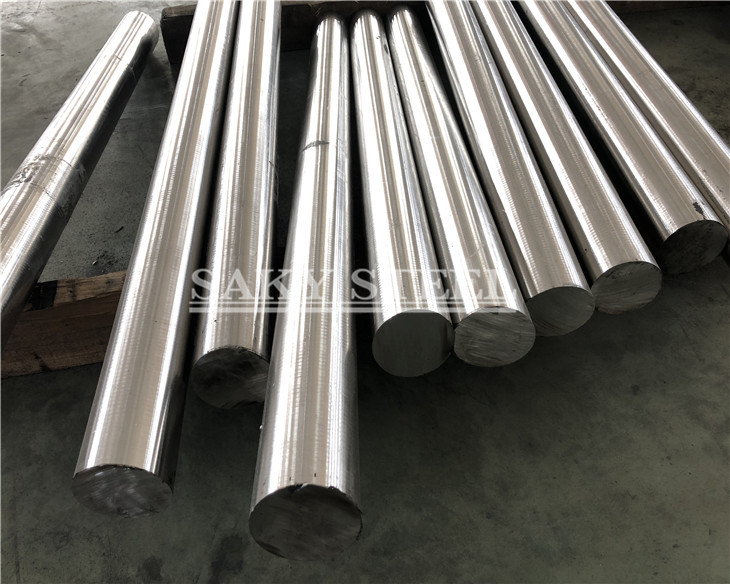

254SMo (S31254) Super Stainless Steel is a special type of stainless steel. It is different from ordinary stainless steel in terms of chemical composition. It refers to a high-alloy stainless steel containing high nickel, high chromium, and high molybdenum. Super stainless steel, nickel-based alloy is a special type of stainless steel, the first chemical composition is different from ordinary stainless steel, refers to a high alloy containing high nickel, high chromium, high-molybdenum stainless steel. The better one is 254Mo, which contains 6% Mo. This type of steel has very good resistance to localized corrosion. It has good resistance to pitting corrosion under seawater, aeration, gaps, and low-velocity erosion conditions (PI ≥ 40) and better stress corrosion resistance, alternative materials for Ni-based alloys and titanium alloys. Second, in the high temperature or corrosion resistance performance, has better resistance to high temperature or corrosion resistance, is 304 stainless steel can not be replaced. In addition, from the classification of stainless steel, the special stainless steel metallographic structure is a stable austenite metallographic structure. Because this special stainless steel is a kind of high-alloy material, it is quite complicated in the manufacturing process. Generally, people can only rely on the traditional process to manufacture this special stainless steel, such as pouring, forging, rolling and so on.

At the same time it has the characteristics of high temperature resistance as follows:

1. A large number of field experiments and extensive experience show that even at slightly elevated temperatures, the 254SMO has high crevice corrosion resistance in seawater, and only a few types of stainless steel have this property.

2. The corrosion resistance of 254SMO in acidic solutions and oxidizing halide solutions such as those required for paper-based bleach production can be compared to nickel-base alloys and titanium alloys that are highly resistant to corrosion.

Post time: Apr-24-2018