Stainless Steel C Channels

Short Description:

Stainless steel channels are structural components made from stainless steel, a corrosion-resistant alloy composed primarily of iron, chromium, nickel, and other elements.

Stainless Steel Channels:

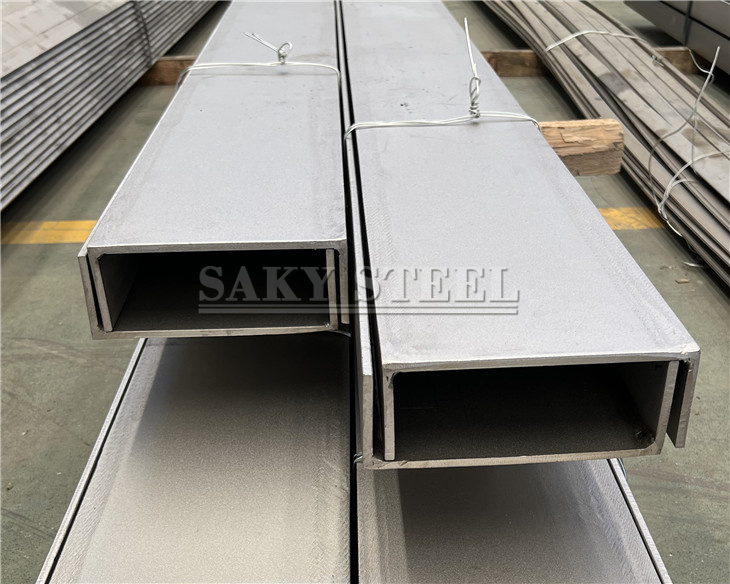

Stainless steel channels are structural profiles made from corrosion-resistant stainless steel alloys, featuring a C-shaped or U-shaped cross-section, suitable for applications in construction, industry, and marine environments. Typically produced through hot rolling or cold bending processes, they offer excellent corrosion resistance and structural support, widely used in constructing frames, manufacturing equipment, marine engineering, and various other applications. Depending on specifications established by standards such as ASTM, EN, etc., different stainless steel grades like 304 or 316 can be chosen to meet the specific requirements of a given project.Stainless steel channels may have different surface finishes, such as polished, brushed, or mill finish, depending on the intended application and aesthetic requirements.

Specifications Of Channels Bar:

| Grade | 302 304 304L 310 316 316L 321 2205 2507 etc. |

| Standard | ASTM A240 |

| Surface | Hot rolled pickled ,polished |

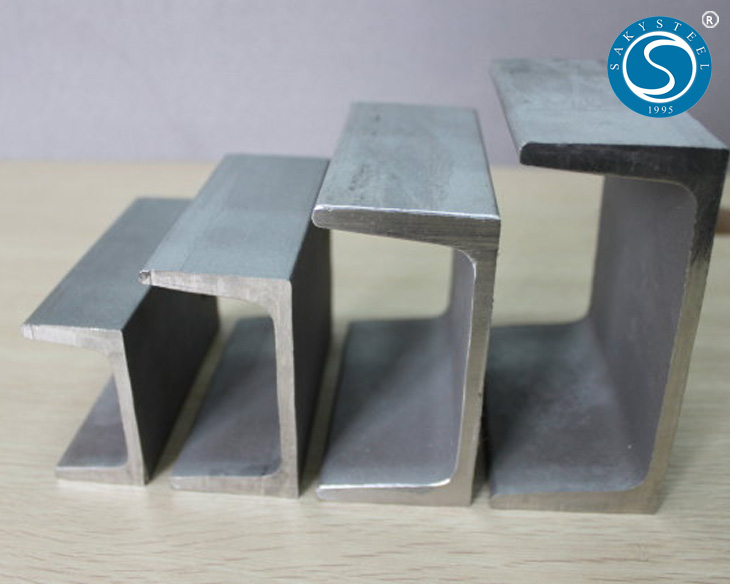

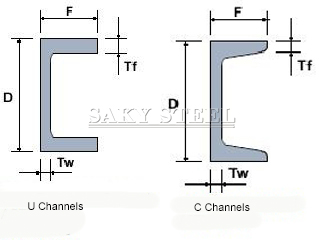

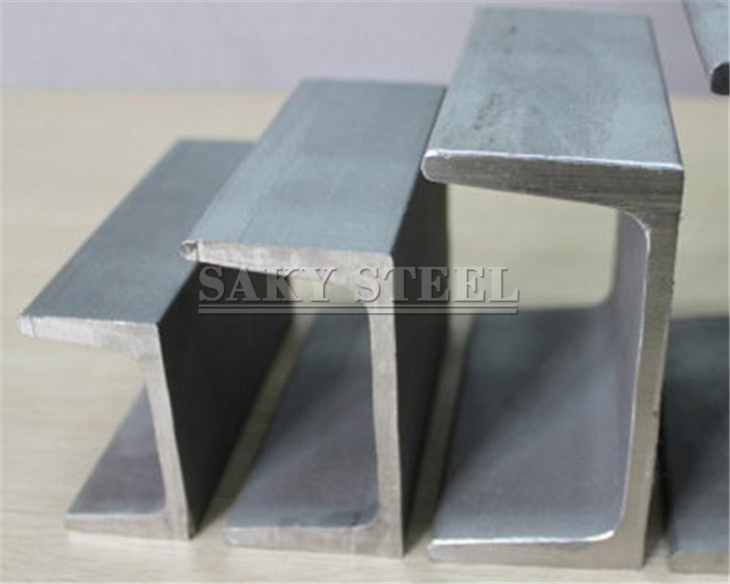

| Type | U Channel / C Channel |

| Technology | Hot Rolled , Welded,Bending |

| Length | 1 to 12 Meters |

C Channels: These have a C-shaped cross-section and are commonly used for structural applications.

U Channels: These have a U-shaped cross-section and are suitable for applications where the bottom flange needs to be attached to a surface.

Types of Channels Bar:

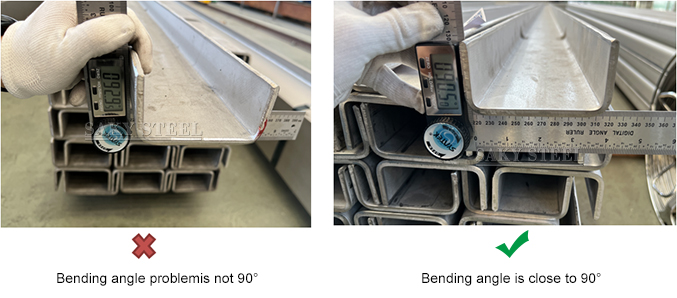

Stainless Steel Bend Channel Straightness:

Angle of bending channel can be controlled in 89 to 91°.

Hot Rolled C Channels Size:

|

C Channels |

WEIGHT

kg / m

|

DIMENSIONS

|

ΔΙΑΤΟΜΗ

|

ΡΟΠΗ ΑΝΤΙΣΤΑΣΕΩΣ

|

||||||||||||||||||||||

|

(mm)

|

(cm2)

|

(cm3)

|

||||||||||||||||||||||||

|

h

|

b

|

s

|

t

|

F

|

Wx

|

Wy

|

||||||||||||||||||||

|

30 x 15

|

1.740

|

30

|

15

|

4.0

|

4.5

|

2.21

|

1.69

|

0.39

|

||||||||||||||||||

|

40 x 20

|

2.870

|

40

|

20

|

5.0

|

5.5

|

3.66

|

3.79

|

0.86

|

||||||||||||||||||

|

40 x 35

|

4.870

|

40

|

35

|

5.0

|

7.0

|

6.21

|

7.05

|

3.08

|

||||||||||||||||||

|

50 x 25

|

3.860

|

50

|

25

|

5.0

|

6.0

|

4.92

|

6.73

|

1.48

|

||||||||||||||||||

|

50 x 38

|

5.590

|

50

|

38

|

5.0

|

7.0

|

7.12

|

10.60

|

3.75

|

||||||||||||||||||

|

60 x 30

|

5.070

|

60

|

30

|

6.0

|

6.0

|

6.46

|

10.50

|

2.16

|

||||||||||||||||||

|

65 x 42

|

7.090

|

65

|

42

|

5.5

|

7.5

|

9.03

|

17.70

|

5.07

|

||||||||||||||||||

|

80

|

8.640

|

80

|

45

|

6.0

|

8.0

|

11.00

|

26.50

|

6.36

|

||||||||||||||||||

|

100

|

10.600

|

100

|

50

|

6.0

|

8.5

|

13.50

|

41.20

|

8.49

|

||||||||||||||||||

|

120

|

13.400

|

120

|

55

|

7.0

|

9.0

|

17.00

|

60.70

|

11.10

|

||||||||||||||||||

|

140

|

16.000

|

140

|

60

|

7.0

|

10.0

|

20.40

|

86.40

|

14.80

|

||||||||||||||||||

|

160

|

18.800

|

160

|

65

|

7.5

|

10.5

|

24.00

|

116.00

|

18.30

|

||||||||||||||||||

|

180

|

22.000

|

180

|

70

|

8.0

|

11.0

|

28.00

|

150.00

|

22.40

|

||||||||||||||||||

|

200

|

25.300

|

200

|

75

|

8.5

|

11.5

|

32.20

|

191.00

|

27.00

|

||||||||||||||||||

|

220

|

29.400

|

220

|

80

|

9.0

|

12.5

|

37.40

|

245.00

|

33.60

|

||||||||||||||||||

|

240

|

33.200

|

240

|

85

|

9.5

|

13.0

|

42.30

|

300.00

|

39.60

|

||||||||||||||||||

|

260

|

37.900

|

260

|

90

|

10.0

|

14.0

|

48.30

|

371.00

|

47.70

|

||||||||||||||||||

|

280

|

41.800

|

280

|

95

|

10.0

|

15.0

|

53.30

|

448.00

|

57.20

|

||||||||||||||||||

|

300

|

46.200

|

300

|

100

|

10.0

|

16.0

|

58.80

|

535.00

|

67.80

|

||||||||||||||||||

|

320

|

59.500

|

320

|

100

|

14.0

|

17.5

|

75.80

|

679.00

|

80.60

|

||||||||||||||||||

|

350

|

60.600

|

350

|

100

|

14.0

|

16.0

|

77.30

|

734.00

|

75.00

|

||||||||||||||||||

|

400

|

71.800

|

400

|

110

|

14.0

|

18.0

|

91.50

|

1020.00

|

102.00

|

||||||||||||||||||

Features & Benefits:

•Stainless steel channels are highly resistant to corrosion, making them suitable for use in various environments, including those with exposure to moisture, chemicals, and harsh weather conditions.

• The polished and sleek appearance of stainless steel channels adds an aesthetic touch to structures, making them suitable for architectural and decorative applications.

• Available in various shapes, including C channels and U channels, stainless steel channels offer versatility in design and can be tailored to fit specific project requirements.

• Stainless steel channels have a long service life, offering extended durability and reducing the need for frequent replacements

• Stainless steel channels resist damage from various chemicals, making them suitable for use in industrial settings where exposure to corrosive substances is common.

• Stainless steel channels can be easily adapted for different applications, allowing for flexibility in design and construction projects.

Chemical Composition C Channels:

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo | Nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 0.75 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.07 | 2.0 | 0.045 | 0.030 | 0.75 | 17.5-19.5 | 8.0-10.5 | - | 0.10 |

| 304L | 0.030 | 2.0 | 0.045 | 0.030 | 0.75 | 17.5-19.5 | 8.0-12.0 | - | 0.10 |

| 310S | 0.08 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 316L | 0.030 | 2.0 | 0.045 | 0.030 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 0.75 | 17.0-19.0 | 9.0-12.0 | - | - |

Mechanical properties Of U Channels:

| Grade | Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 75[515] | 30[205] | 40 |

| 304L | 70[485] | 25[170] | 40 |

| 310S | 75[515] | 30[205] | 40 |

| 316 | 75[515] | 30[205] | 40 |

| 316L | 70[485] | 25[170] | 40 |

| 321 | 75[515] | 30[205] | 40 |

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

How to bend stainless steel channel?

Bending stainless steel channels requires the use of appropriate tools and methods. Begin by marking the bending points on the channel and securing it firmly in a bending machine or press brake. Adjust the machine settings, perform a test bend to ensure accuracy, and proceed with the actual bending, closely monitoring the process and checking the bend angle. Repeat the process for multiple bending points, make any necessary finishing touches such as deburring, and adhere to safety guidelines by wearing proper personal protective equipment throughout the procedure.

What are the applications of stainless steel channel?

Channel steel is a versatile structural material widely used in construction, manufacturing, automotive, maritime, energy, power transmission, transportation engineering, and furniture production. Its distinctive shape, combined with superior strength and corrosion resistance, makes it an ideal choice for constructing frameworks, support structures, machinery, vehicle chassis, energy infrastructure, and furniture. Stainless steel channel steel is commonly employed in the chemical and industrial sectors for manufacturing equipment supports and pipeline brackets, highlighting its significance across various industries.

What are the problems with the bending angle of channel?

Issues with the bending angle of stainless steel channels may encompass inaccuracies, uneven bending, material distortion, cracking or fracturing, springback, tooling wear, surface imperfections, work hardening, and tooling contamination. These problems can arise from factors such as incorrect machine settings, material variations, excessive force, or inadequate tool maintenance. To address these issues, it is crucial to adhere to proper bending procedures, utilize appropriate tooling, regularly maintain equipment, and ensure that the bending process aligns with industry standards, minimizing the risk of compromising the quality, accuracy, and structural integrity of the stainless steel channels.

Our Clients

Feedbacks From Our Clients

Stainless steel channels stand out with their outstanding corrosion resistance and remarkable durability, ensuring excellence in various challenging environments. The straightforward installation process provides convenience for users, while the multifunctional design excels in cable management and pipe guidance. The refined and modern exterior design not only meets practical functional needs but also adds aesthetic appeal to the space. Stainless steel channels represent a reliable long-term investment, offering customers a high-quality, stable, and versatile solution.

Stainless Steel C Channels Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,