Covfusing txoj kev ntawm stainless hlau hlau hluafeem ntau yog hais txog kev siv vuam lossis kev sib txuas tshuab siv thaum lub sij hawm kev sib txuas, kev sib koom ua ke lossis kev txiav cov hlua hlau.

1.Ordinary Melting

Lus Txhais: Ordinary melting muaj cua sov qhov chaw sib cuag ntawm cov hlau hlau hlua mus rau qhov kub siab, ua rau nws yaj thiab fuse. Lub melted ib feem solidifies raws li nws txias, tsim ib tug muaj zog kev twb kev txuas, feem ntau yog siv rau txoj hlua txoj hlua khi.

Cov yam ntxwv: Cov txheej txheem melting feem ntau yog siv rau kev sib txuas ntawm lub zog siab, thiab qhov chaw welded feem ntau muaj lub zog zoo ib yam li lossis qis dua cov hlua hlau nws tus kheej. Nws yog tsim rau feem ntau steel hlau hlua sib koom ua ke, thiab kev sib koom ua ke yog feem ntau ruaj khov.

2. Soldering

Lus Txhais: Soldering yuav tsum tau siv ib tug uas tsis muaj-kub alloy (xws li tin) kom yaj thiab khi rau steel hlau hlua qhov sib koom ua ke cheeb tsam. Qhov kub uas siv rau hauv soldering yog qhov qis thiab feem ntau yog ua haujlwm rau txoj kab uas hla me me lossis cov hlua sib dua, lossis rau cov ntawv thov uas xav tau hluav taws xob conductivity.

Yam ntxwv: Lub zog ntawm kev sib koom ua ke yog feem ntau qis dua li qhov sib xyaw ua ke, ua rau nws tsim nyog rau cov ntawv thov uas tsis cuam tshuam nrog cov khoom hnyav. Qhov zoo ntawm soldering yog tias nws ua haujlwm ntawm qhov kub thiab txias, uas tiv thaiv kev puas tsuaj rau cov khoom. Txawm li cas los xij, nws qhov kev poob qis yog qhov sib koom ua ke lub zog feem ntau qis dua.

3. Spot Vuam

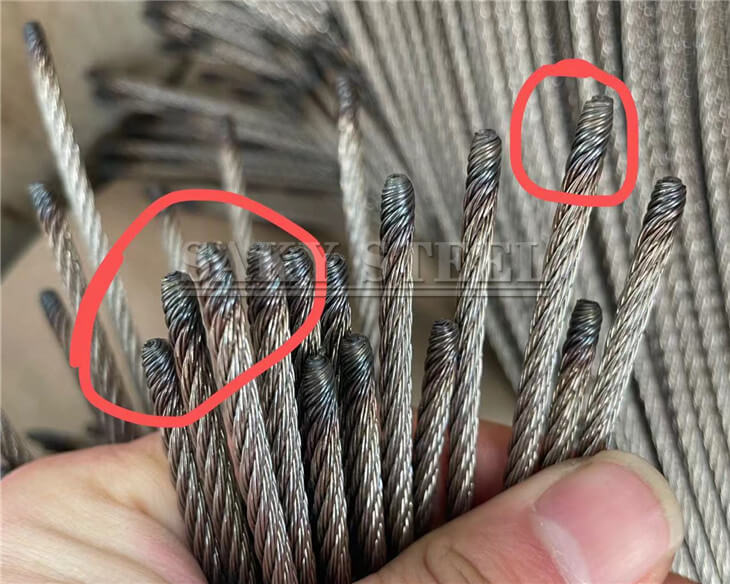

Txhais: Spot welding yog txheej txheem uas cov khoom siv hluav taws xob tau dhau los ntawm cov hlua hlau ntawm qhov sib koom ua ke, ua kom muaj cua sov kom yaj thiab txuas ob feem. Cov txheej txheem no feem ntau tsim ib lossis ntau qhov sib txuas me me, feem ntau siv rau kev sib txuas ntau cov xov hlau los yog qhov kawg ntawm cov hlua hlau.

Yam ntxwv: Spot welding yog tsim rau me me steel hlau hlua pob qij txha. Vim yog qhov chaw vuam me me, nws feem ntau yog siv rau cov ntawv siv sib dua. Qhov zoo dua yog kev sib txuas ceev, tab sis lub zog vuam nyob ntawm thaj tsam ntawm qhov sib koom ua ke.

4. Rectangular Melting

Txhais: Rectangular melting yog ib txoj hauv kev uas qhov kawg ntawm cov hlua hlau hlau yog melted thiab tom qab ntawd tsim rau hauv cov duab plaub los tsim kev sib txuas. Txoj kev no yog siv thaum yuav tsum tau muaj cov duab tshwj xeeb lossis sealing nyhuv.

Yam ntxwv: Rectangular melting cuam tshuam nrog melting thiab rov tsim cov kev sib koom ua ke rau hauv cov qauv duab plaub, muab kev sib txuas zoo dua. Nws feem ntau yog siv rau hauv daim ntawv thov uas xav tau kev sib koom ua ke kom muaj zog los yog ntau dua kev ruaj ntseg, tshwj xeeb tshaj yog rau kev sib txuas ntawm steel hlau hlua.

Cov ntsiab lus

Cov txheej txheem melting los yog vuam no txhua tus muaj lawv qhov zoo thiab qhov tsis zoo. Txoj kev tsim nyog raug xaiv raws li daim ntawv thov tshwj xeeb:

• Ib qho yooj yim meltingyog tsim rau cov kev sib txuas muaj zog uas yuav tsum tau tiv taus ntau dua.

• SolderingNws yog qhov zoo dua rau kev siv cov khoom siv sib dua, tshwj xeeb tshaj yog qhov yuav tsum tau muaj qhov kub thiab txias.

• Spot vuamyog siv rau kev sib txuas ceev, feem ntau hauv cov hlau me me hlau hlua pob qij txha.

• Rectangular meltingyog qhov zoo tagnrho rau kev tsim cov duab sib koom ua ke thiab muab kev ruaj ntseg zoo dua.

Post lub sij hawm: Jan-07-2025