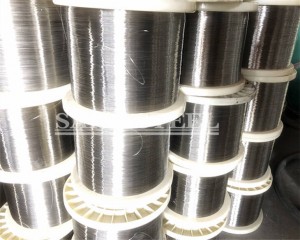

Nickel 200 Hlau | UNS N02200 Ntshiab Nickel Hlau

Lus piav qhia luv luv:

Nickel 200 hlau (UNS N02200) tsum. High purity ≥99.5% Ni hlau rau tshuaj lom neeg, marine, thiab hluav taws xob siv. Custom size, ceev xa los ntawmsakysteel ua.

Nickel 200 hlau, tseem hu uaUNS N02200 xaim, yog cov khoom lag luam ntshiab wrought npib tsib xee (tsawg kawg 99.5% cov ntsiab lus npib tsib xee). Qhov no high-purity npib tsib xee xaim muaj kev tiv thaiv corrosion zoo heev hauv kev txo qis thiab nruab nrab cov xov xwm, cov khoom siv kho tshuab zoo, thiab cov hluav taws xob zoo dua thiab thermal conductivity.

PebNickel 200 hlauyog siv dav hauv cov khoom siv hluav taws xob, cov khoom siv tshuaj lom neeg, cov khoom siv hauv hiav txwv, thiab cov khoom siv hluav taws xob. Nws yog qhov zoo tagnrho rau cov ntawv thov uas xav tau cov khoom siv siab, cov khoom sib nqus, thiab kev ua haujlwm tshwj xeeb hauv caustic alkalis.

| Specifications ntawm 200 Nickel Hlau: |

| Specifications | ASTM B160, GB / T21653 |

| Qib | N7(N02200),N4,N5,N6 |

| Hlau txoj kab uas hla | 0.50mm txog 10mm |

| Nto | Dub, ci, Polished |

| Qhov xwm txheej | Annealed / Hard / Raws li kos |

| Daim ntawv | Hlau Bobbin, Hlau Chev, Filler Hlau, Coils |

Qib thiab cov qauv siv tau

| Qib | Phaj Standard | Sawb Standard | Tube Standard | Qws Standard | Hlau Standard | Forging Standard |

|---|---|---|---|---|---|---|

| N4 | GB/T2054-2013NB/T47046-2015 | GB/T2072-2007 | GB/T2882-2013NB/T47047-2015 | GB/T4435-2010 | GB/T21653-2008 | NB/T47028-2012 |

| N5 (N02201) | GB / T2054-2013ASTM B162 | GB / T2072-2007ASTM B162 | GB / T2882-2013 ASTM B161 | GB / T4435-2010ASTM B160 | GB/T26030-2010 | |

| N6 | GB/T2054-2013 | GB/T2072-2007 | GB/T2882-2013 | GB/T4435-2010 | ||

| N7 (N02200) | GB / T2054-2013ASTM B162 | GB / T2072-2007ASTM B162 | GB / T2882-2013 ASTM B161 | GB / T4435-2010ASTM B160 | GB/T26030-2010 | |

| N8 | GB/T2054-2013 | GB/T2072-2007 | GB/T2882-2013 | GB/T4435-2010 | ||

| DN | GB/T2054-2013 | GB/T2072-2007 | GB/T2882-2013 |

| Chemical Composition UNS N02200 Hlau: |

| Qib | C | Mn | Si | Cu | Cr | S | Fe | Ni |

| UNS N02200 | 0.15 | 0.35 Nws | 0.35 Nws | 0.25 | 0.2 | 0.01 ib | 0.40 Nws | 99.5 ua |

| Cov yam ntxwv tseem ceeb ntawm Ni 99.5% Hlau: |

-

High Purity Nickel (≥99.5% Ni)

Nickel 200 hlau yog tsim los ntawm kev lag luam ntshiab npib tsib xee nrog kev ruaj ntseg tshuaj zoo heev. -

Zoo heev Corrosion Resistance

Kev ua tau zoo tshaj plaws nyob rau hauv ib puag ncig caustic alkali, nruab nrab thiab txo cov xov xwm. -

Zoo Mechanical Properties

Muab cov ductility siab, qis ua haujlwm hardening tus nqi, thiab zoo toughness ntawm ntau qhov kub thiab txias. -

Superior Electrical thiab Thermal Conductivity

Haum rau cov khoom siv hluav taws xob, electrodes, thiab thermal hloov daim ntaub ntawv. -

Magnetic Properties

Nickel 200 hlau yog sib nqus ntawm chav tsev kub, ua rau nws haum rau cov ntawv thov electromagnetic. -

Zoo Fabricability thiab Weldability

Yooj yim rau kev tsim, kos duab, thiab vuam, haum rau kev siv hlau zoo, mesh, thiab cov khoom sib txawv. -

Ntau yam ntawm qhov ntau thiab tsawg

Muaj nyob rau hauv txoj kab uas hla ntawm 0.025 hli mus rau 6 hli, nkag rau hauv coil, spool, lossis ncaj ntev. -

Ua raws li International Standards

Raws li ASTM B160, UNS N02200, thiab GBT 21653-2008 specifications.

| Nickel 200 Alloy Hlau Daim Ntawv Thov: |

-

Cov khoom siv tshuaj ua haujlwm

Siv nyob rau hauv caustic alkali ntau lawm, lim, cov ntxaij vab tshaus, thiab tshuaj reactors vim nws zoo heev corrosion kuj. -

Cov khoom siv hluav taws xob thiab hluav taws xob

Siv nyob rau hauv cov hlau lead-hauv xov hlau, roj teeb connectors, cov ntaub ntawv electrode, thiab hluav taws xob tiv tauj vim nws cov hluav taws xob conductivity zoo. -

Marine thiab offshore engineering

Haum rau seawater-resistant Cheebtsam thiab mesh nyob rau hauv marine ib puag ncig. -

Aerospace thiab nuclear kev lag luam

Siv nyob rau hauv tshwj xeeb high-purity daim ntaub ntawv uas superior corrosion kuj yuav tsum tau. -

Hlau mesh, woven screens, thiab lim

Nickel 200 hlau feem ntau yog siv rau hauv kev tsim cov ntaub ntawv xov hlau thiab pom cov tshuab rau corrosive ib puag ncig. -

Thermocouple Cheebtsam thiab hluav taws xob cua sov ntsiab

Siv nyob rau hauv cov khoom uas yuav tsum tau siab thermal conductivity thiab stability. -

Fasteners thiab fasteners

Siv nyob rau hauv bolts, ceev, thiab springs uas yuav tsum tau siab corrosion kuj.

| FAQ: |

Q1 Dab tsi yog qib purity ntawm Nickel 200 Hlau

A1Nickel 200 Hlau muaj qhov tsawg kawg nkaus ntawm 99.5 feem pua nickel ntshiab ua rau nws tsim nyog rau kev ua cov tshuaj siv hluav taws xob thiab kev siv dej hiav txwv.

Q2 Cov qauv dab tsi ua rau Nickel 200 Hlau ua raws li

A2Nws yog tsim raws li ASTM B160 thiab raug xaiv los ua UNS N02200 hauv cov qauv thoob ntiaj teb

Q3 Dab tsi yog cov kev siv ntau ntawm Nickel 200 Hlau

A3Nickel 200 Hlau yog dav siv nyob rau hauv chemical ua hluav taws xob connectors roj teeb Cheebtsam marine hardware hlau mesh lim thiab hluav taws xob qhov chaw

Q4 Yog Nickel 200 Hlau Sib Nqus

A4Yog Nickel 200 Hlau yog sib nqus ntawm chav tsev kub uas tuaj yeem siv tau hauv cov ntawv thov electromagnetic

| Vim li cas thiaj xaiv SAKYSTEEL : |

Kev ntseeg tau zoo- Peb stainless hlau tuav, kav, coils, thiab flanges yog tsim kom tau raws li thoob ntiaj teb cov qauv xws li ASTM, AISI, EN, thiab JIS.

Kev soj ntsuam nruj- Txhua yam khoom tau dhau los kuaj ultrasonic, tshuaj ntsuam xyuas tshuaj, thiab kev tswj qhov ntev kom ntseeg tau tias muaj kev ua haujlwm siab thiab traceability.

Muaj zog Tshuag & xa khoom sai- Peb tuav cov khoom muag tsis tu ncua ntawm cov khoom tseem ceeb los txhawb kev txiav txim sai thiab kev xa khoom thoob ntiaj teb.

Customized Solutions- Los ntawm kev kho cua sov mus rau qhov chaw tiav, SAKYSTEEL muaj cov kev xaiv tsim kom haum rau koj cov kev xav tau tiag tiag.

Pab neeg tshaj lij- Nrog xyoo dhau los ntawm kev xa tawm, peb pab pawg muag khoom thiab kev txhawb nqa kev ua haujlwm kom muaj kev sib txuas lus zoo, cov lus hais ceev, thiab cov ntaub ntawv tag nrho.

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj): |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev soj ntsuam cuam tshuam

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kev xeem

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev Ntsuas Roughness

10. Metallography Experimental Test

| SAKY STEEL Ntim: |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,