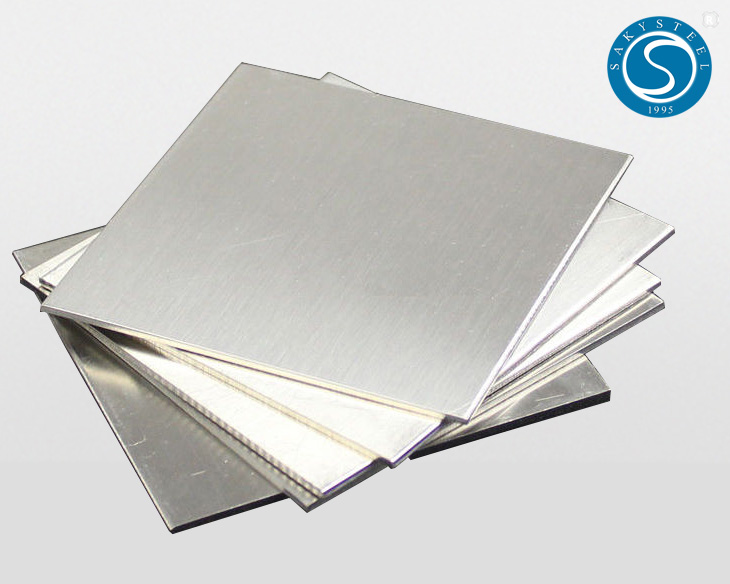

317 Leqephe la Ts'epi

Tlhaloso e Khutšoanyane:

| Litlhaloso tsaletlapa la tšepe e sa hloekang: |

Litlhaloso :ASTM A240 / ASME SA240

Kereiti:304L, 316L, 317, 317L, 409L, 321,347, 347H, 410, 420, 253SMA, 254SMO, 2205

Bophara :1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, joalo-joalo.

Bolelele :2000mm, 2440mm, 3000mm, 5800mm, 6000mm, joalo-joalo.

Botenya :0.3 ho isa ho 60 mm

Surface Finish :Letlapa le chesang (HR), Cold rolled sheet (CR), 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, seipone, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) joalo-joalo.

Foromo :Li-Coils, Foil, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Checkered Plate, Strip, Flats, Blank (Circle), Ring (Flange) joalo-joalo.

| Stainless Steel 317/317L Maqephe le Lipoleiti Mephato e Tšoanang: |

| TS'ELISO | WERKSTOFF NR. | UNS | JIS | EN |

| SS317 | 1.4449 | S31700 | SUS 317 | - |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

| Lipampiri tsa SS 317 / 317L, Sebopeho sa Lik'hemik'hale tsa Lipoleiti le thepa ea Mechini: |

| Mephato | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS317 | 0.08 max | 2.0 max | 1.0 max | 0.045 boholo | 0.030 boholo | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 mets |

| SS 317L | 0.035 boholo | 2.0 max | 1.0 max | 0.045 boholo | 0.030 boholo | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 mets |

| Botenya | Melting Point | Matla a tšepe | Matla a Hlahisa (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi - 75000 , MPa - 515 | Psi - 30000 , MPa - 205 | 35 % |

| Ke Hobane'ng ha U Re Khetha: |

1. U ka fumana boitsebiso bo phethahetseng ho ea ka tlhokahalo ea hau bonyane theko e ka khonehang.

2. Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

3. Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela.(Litlaleho li tla hlaha ho latela tlhoko)

4. e tiisetso ea ho fana ka karabo nakong ea lihora tse 24(hangata ka hora e tšoanang)

5. U ka fumana mefuta e meng ea li-stock, ho tsamaisoa ha leloala ka ho fokotsa nako ea tlhahiso.

6. Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

| Netefatso ea Boleng ea SAKY STEEL (ho kenyeletsoa tse senyang le tse sa senyeheng) : |

1. Teko ea Visual Dimension

2. Tlhahlobo ea mochine joalo ka tensile, Elongation le phokotso ea sebaka.

3. Tlhahlobo ea phello

4. Tlhahlobo ea tlhahlobo ea lik'hemik'hale

5. Teko ea boima

6. Teko ea tšireletso ea likoti

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Teko ea ho Roughness

10. Metallography Teko ea Teko

| Sephutheloana sa SAKY STEEL'S: |

1. Ho paka ho bohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,

Lisebelisoa:

1. Tšebeliso ea Lik'hemik'hale

2. Phetoho ea Lijo - lisebelisoa le polokelo

3. Petroleum Refining - fluid catalytic cracking units, tšebeletso ea acid ea polythionic

4. Tlhahiso ea Meriana

5. Litšila tsa ho tsosolosa mocheso - li-recuperators