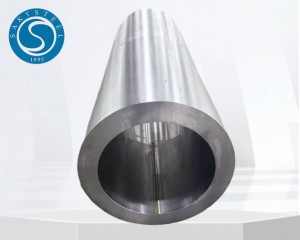

DIN 1.2311 P20 Mold Chitsulo

Kufotokozera Kwachidule:

DIN 1.2311 ″ ndi mtundu wamba wachitsulo cha nkhungu, chomwe nthawi zambiri chimatchedwa P20 chitsulo. P20 ndi chitsulo chochepa cha alloy mold chomwe chimadziwika chifukwa cha makina ake abwino komanso kukana kuvala, chomwe chimagwiritsidwa ntchito popanga nkhungu zapulasitiki ndi zotayira.

DIN 1.2311 P20 Mold Chitsulo:

DIN 1.2311 P20 Mold Steel ndi zitsulo zomwe zimagwiritsidwa ntchito popanga nkhungu, zomwe zimagwiritsidwa ntchito kwambiri popanga nkhungu za pulasitiki ndi zowonongeka zowonongeka.DIN 1.2311 P20 Mold Steel ili ndi ntchito yabwino kwambiri yodulira komanso makina, zomwe zimapangitsa kuti zikhale zosavuta kuzipanga mumitundu yosiyanasiyana. oyenerera kupanga nkhungu zokhala ndi zofunikira kwambiri.DIN 1.2311 P20 Mold Steel imagwiritsidwa ntchito popanga mitundu yosiyanasiyana ya nkhungu monga jekeseni wa jekeseni, ma extrusion molds, die-casting molds, and mold bases.

Zofotokozera za 1.2311 ZIZAMBIRO:

| Gulu | 1.2311, P20 |

| Standard | Chithunzi cha ASTM A681 |

| Pamwamba | Wakuda; Peeled; Wopukutidwa; Zopangidwa; Wopukutidwa; Kutembenuka; Milled |

| Zofunika Kwambiri | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

1.2311 Magiredi Ofanana Azitsulo:

| Dziko | USA | Chijeremani | GB/T |

| Standard | Chithunzi cha ASTM A681 | DIN EN ISO 4957 | GB/T 1299 |

| Maphunziro | P20 | 1.2311 | 3Cr2Mo |

P20 Tool Steel Mapangidwe a Chemical:

| Standard | Gulu | C | Si | Mn | P | S | Cr | Mo |

| Chithunzi cha ASTM A681 | P20 | 0.28-0.40 | 0.2 ~ 0.8 | 0.60-1.0 | ≤0.030 | ≤0.030 | 1.4 ~ 2.0 | 0.3 - 0.55 |

| Mtengo wa GB/T9943 | 3Cr2Mo | 0.28-0.40 | 0.2 ~ 0.8 | 0.60-1.0 | ≤0.030 | ≤0.030 | 1.4 ~ 2.0 | 0.3 - 0.55 |

| Chithunzi cha ISO4957 | 1.2311 | 0.35 ~ 0.45 | 0.2 ~ 0.4 | 1.3-1.6 | ≤0.030 | ≤0.030 | 1.8-2.1 | 0.15 ~ 0.25 |

1.2311 Tool Steels Mechanical Properties:

| Katundu | Metric |

| Kuuma, Brinell (Wamba) | 300 |

| Kuuma, Rockwell C (Wanthawi zonse) | 30 |

| Mphamvu Yamphamvu, Yomaliza | 965-1030 MPa |

| Kulimbitsa Mphamvu, Zokolola | 827-862 MPa |

| Elongation At Break (Mu 50 Mm (2″) | 20.00% |

| Compressive Mphamvu | 862 MPA |

| Charpy Impact (V-Notch) | 27.1-33.9 J |

| Chiwerengero cha Poisson | 0.27-0.30 |

| Elastic Modulus | 190-210 GPA |

Chifukwa Chiyani Mutisankhe?

•Mutha kupeza zinthu zabwino kwambiri malinga ndi zomwe mukufuna pamtengo wotsika kwambiri.

•Timaperekanso Reworks, FOB, CFR, CIF, ndi mitengo yoperekera khomo ndi khomo. Tikukulangizani kuti mugwiritse ntchito zotumiza zomwe zingakhale zotsika mtengo.

•Zipangizo zomwe timapereka ndizotsimikizika kotheratu, kuyambira pa satifiketi yoyeserera ya zinthu zosaphika mpaka pachiwonetsero chomaliza. (Malipoti awonetsedwa pakufunika)

•Timatsimikizira kuti tipereka yankho mkati mwa 24hours (nthawi zambiri mu ola lomwelo)

•Perekani lipoti la SGS TUV.

•Ndife odzipereka kwathunthu kwa makasitomala athu. Ngati sizingatheke kukwaniritsa zomwe mukufuna mutapenda zonse zomwe mungasankhe, sitidzakusocheretsani popanga malonjezo abodza omwe angapangitse ubale wabwino ndi makasitomala.

•Perekani ntchito yoyimitsa kamodzi.

Ntchito Zathu

1. Kutentha ndi kuzizira

2.Vacuum kutentha mankhwala

3.Mirror-opukutidwa pamwamba

4.Precision-milled kumaliza

4.CNC Machining

5.Kubowola molondola

6.Dulani muzigawo zing'onozing'ono

7.Achieve mold ngati mwatsatanetsatane

Kulongedza:

1. Kulongedza ndi kofunika kwambiri makamaka ngati katundu wapadziko lonse lapansi amadutsa munjira zosiyanasiyana kuti akafike komwe akupita, chifukwa chake timayika chidwi chapadera pakuyika.

2. Saky Steel's amanyamula katundu wathu m'njira zambiri kutengera zomwe timapanga. Timanyamula katundu wathu m'njira zingapo, monga,