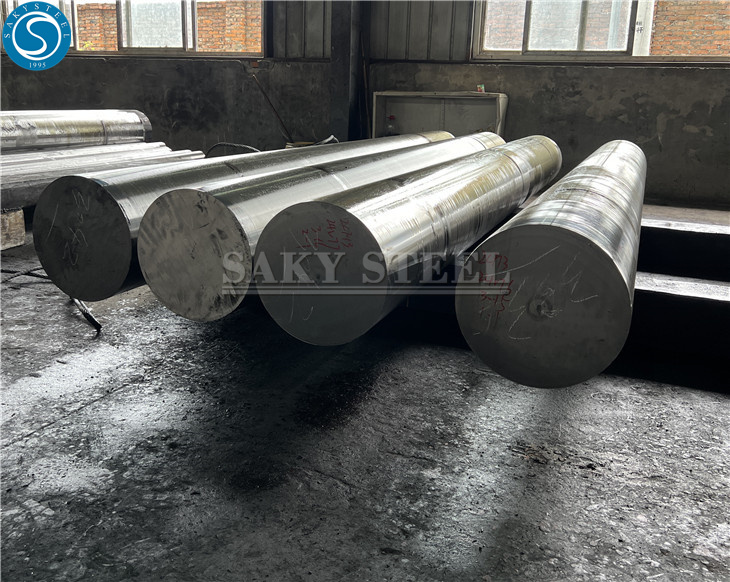

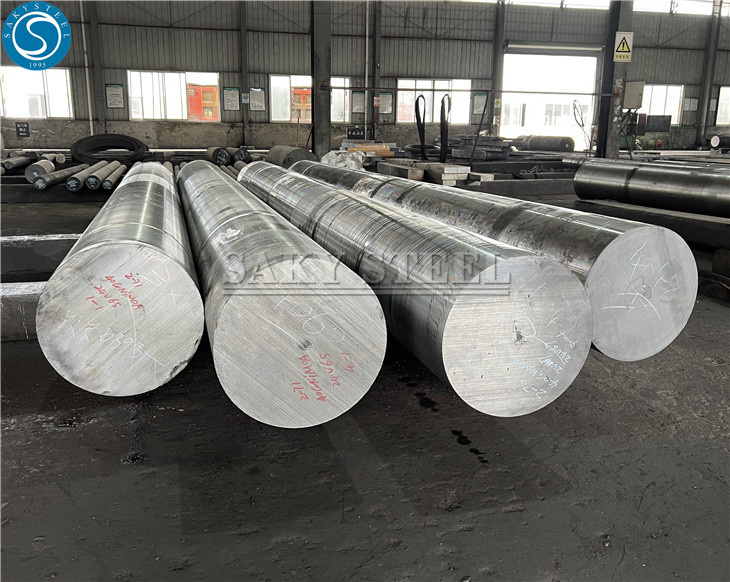

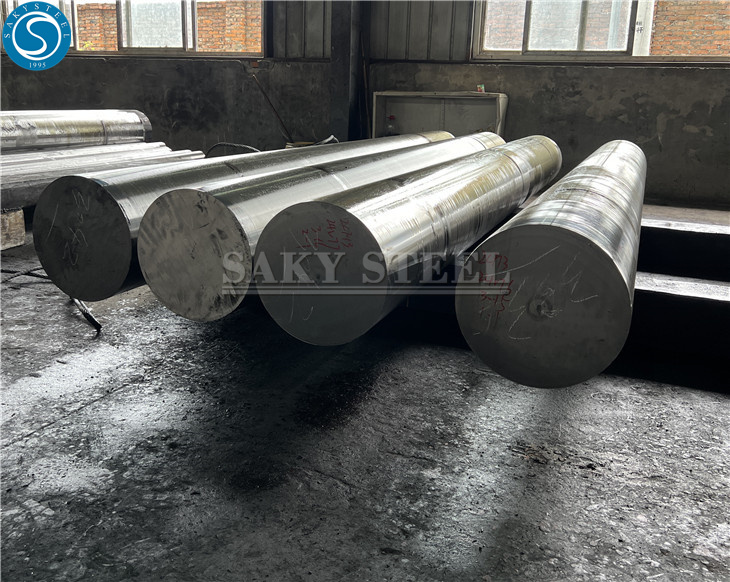

AISI 4317 (25CrMo4) Alloy Steel Round Bar & Forging Stock

ʻO ka wehewehe pōkole:

ʻO AISI 4317 / 25CrMo4 (1.7218) he kila kila chromium-molybdenum i ʻike ʻia no kona ikaika kiʻekiʻe, paʻakikī, a me ka paʻakikī maikaʻi. Hoʻohana nui ʻia ia no nā ʻāpana forged e like me nā shafts, gears, a me nā koʻokoʻo hoʻohui i nā noi automotive a me nā mechanical.

AISI 4317 Alloy Steel Round Bar:

ʻO AISI 4317, i kapa ʻia ʻo 25CrMo4 a i ʻole DIN 1.6582, he kila chromium-molybdenum haʻahaʻa haʻahaʻa haʻahaʻa e hāʻawi ana i ka ikaika maikaʻi, paʻakikī, a me ke kūpaʻa. Hoʻohana maʻamau ia i ka hana ʻana i nā ʻāpana forged kiʻekiʻe e like me nā shafts, gears, crankshafts, a me nā lāʻau hoʻohui. Hoʻolakoʻia i loko o ka'ōwili wela a iʻole keʻano i hoʻopiliʻia, ua kūpono kēia pae kila no ke kinai a me ka hoʻouluʻana e hoʻokō i nā mea mechanical kiʻekiʻe. Hāʻawi ʻo Saky Steel i nā pahu pōʻai a me nā forging maʻamau me nā ana kikoʻī a me ka traceability piha e like me nā kūlana honua.

Nā kikoʻī o 1.6582 pahu kila:

| Papa | 4317 / 25CrMo4 |

| Ili | ʻeleʻele; Peeled; Hoʻomaʻamaʻa ʻia; Mīkini; wili ʻia; Huli; Milled |

| Kaʻina hana | Huki Anuanu & Ho'oma'ama'a Huki Anuanu, 'Āina Waena 'ole & Polished |

| Palapala Hoao Mill | En 10204 3.1 a i ʻole En 10204 3.2 |

ʻO 25CrMo4 Steel Rod E like me:

| DIN | JIS | AFNOR |

| 1.6582 | SCM420H | 25CD4 |

ʻO AISI 4317 bar ka hoʻohui ʻana i nā mea hoʻonaninani:

| C | Si | Mn | Cr | Mo | Ni |

| 0.17-0.23 | 0.15-0.35 | 0.60-0.90 | 0.9-1.2 | 0.15-0.30 | 1.3-1.7 |

25CrMo4 pahu poepoe Mechanical Properties:

| Ka ikaika uʻi (MPa) | Elongation (%) | Ka ikaika o ka hua (MPa) | ʻoʻoleʻa |

| 850–1000 MPa | 14 | ≥ 650 MPa | ≤ 229 HBW (i hoʻopili ʻia) |

Nā hiʻohiʻona o AISI 4317 Steel:

• 'Oi loa hardenability a me ka lole pale

• Ka ikaika tensile maikaʻi a me ke kūpaʻa luhi

• He kūpono no ka carburizing a i ʻole ka nitriding lapaʻau

• maikaʻi machinability a weldability

Nā noi o 25CrMo4 pā kila kila:

• Nā Gear, nā kumu, a me nā ʻāpana hoʻoili

• Nā mea kaʻa kaumaha kaumaha

• Nā ʻāpana mea hana mīkini

• Nā ʻōnaehana hydraulic a me nā ʻōnaehana kaomi

No ke aha e koho ai iā mākou?

•Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

•Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka i ka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

•Hiki ke hōʻoia ʻia nā mea a mākou e hāʻawi ai, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope. (E hōʻike ʻia nā hōʻike ma ke koi)

•Ke hōʻoiaʻiʻo nei mākou e hāʻawi i kahi pane i loko o 24 mau hola (maʻamau i ka hola hoʻokahi)

•Hāʻawi i ka hōʻike SGS TUV.

•Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

•Hāʻawi i ka lawelawe hoʻokahi.

ʻO kā mākou lawelawe

1.Quenching a me ka tempering

2.Vacuum wela mālama

3.Mirror-polished ili

4.Precision-milled pau

4.CNC machining

5.Precision wili

6.ʻokiʻoki i nā'āpana liʻiliʻi

7. Loaʻa i ka pololei e like me ka mold

AISI 4317 kila Paʻi:

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,