1.2394 Tool Steel - Kev Ua Haujlwm Siab Ua Haujlwm Txias Hlau Alloy Steel

Lus piav qhia luv luv:

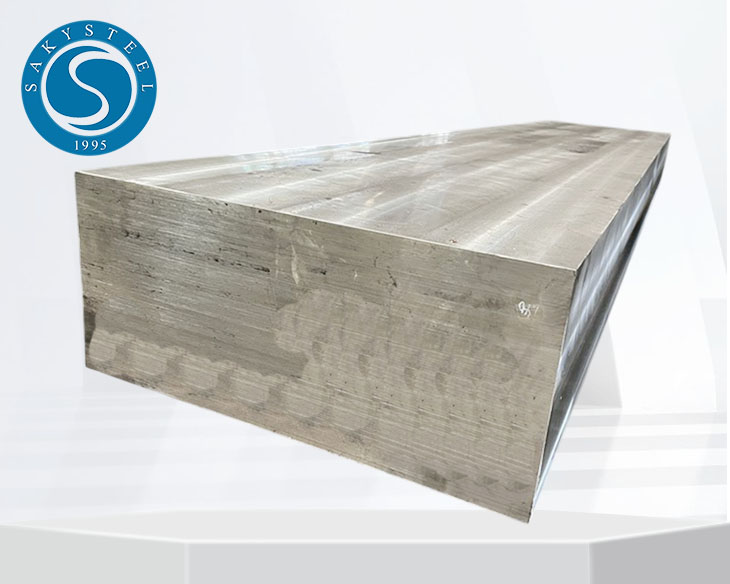

1.2394 steel hlauyog ib qho high-carbon, high-chromium, thiab tungsten-molybdenum alloyed cuab yeej hlau, paub txog nws qhov tshwj xeeb hnav tsis kam thiab qhov ruaj khov. Nws feem ntau yog siv rau hauv cov ntawv ua haujlwm txias uas xav tau kev ua haujlwm zoo dua thiab ruaj khov.

DIN 1.2394 cov cuab yeej steel, tseem hu ua X153CrMoV12, yog cov pa roj carbon ntau, siab-chromium txias ua haujlwm alloy hlau. Renowned rau nws zoo heev hnav tsis kam thiab zoo heev dimension stability, cov khoom no yog zoo tagnrho rau kev thov txias ua hauj lwm daim ntaub ntawv xws li blanking, xuas nrig ntaus, thiab txiav cov cuab yeej.1.2394 yog piv rau AISI D6 nyob rau hauv ASTM A681, muab zoo sib xws hardness, compressive zog, thiab hnav tsis kam, thaum tuav zoo toughness tom qab kev kho cua sov. Nws yog feem ntau siv nyob rau hauv daim ntaub ntawv uas siab hardness thiab tsawg distortion yuav tsum tau.

| Specifications ntawm 1.2394 Tool Steel: |

| Qib | 1.2394 ib |

| Thickness kam rau ua | -0.1 ~ 0.1 hli |

| Flatness | 0.01 / 100 hli |

| Technology | Kub Rolled / Forged / Cold Drawn |

| Nto roughness | Ra ≤1.6 lossis Rz ≤6.3 |

| Cold Work Tool Steel 1.2394 Qib sib npaug: |

| STANDARD | AISI | ISO |

| 1.2394 ib | D6 (ib feem sib npaug) | 160CrMoV12 |

| Chemical Composition DIN 1.2394 Hlau: |

| C | Cr | Mn | Mo | V | Si |

| 1.4-1.55 Nws | 11.0-12.5 Nws | 0.3-0.6 hli | 0.7-1.0 Nws | 0.3-0.6 hli | 0.2-0.5 hli |

| Ntsiab nta X153CrMoV12 Tool Steel: |

-

Zoo heev hnav tsis kam: High carbon thiab alloy cov ntsiab lus kom zoo heev abrasive hnav tsis kam nyob rau hauv high-pressure tooling ib puag ncig.

-

Zoo Dimensional Stability: Zoo tagnrho rau cov cuab yeej precision, tswj cov duab thiab loj tom qab hardening.

-

Siab Compressive zog: Nrog hnyav loads thiab shocks yam tsis muaj deformation.

-

Toughness: Muab qhov sib npaug ntawm hardness thiab toughness, tiv thaiv chipping los yog cracking.

-

Thaum tshav kub kub kho tau: tuaj yeem ua kom tawv rau 60-62 HRC thaum tseem tuav cov ductility.

| FAQ |

1. 1.2394 cov cuab yeej steel siv rau dab tsi?

1.2394 feem ntau yog siv rau kev ua haujlwm txias, suav nrog kev tuag tuag, txiav cov hniav, cov cuab yeej txiav, thiab ua cov punches. Nws lub siab hnav tsis kam ua rau nws zoo tagnrho rau kev ua haujlwm nrog kev ntxhov siab thiab puas.

2. Puas yog 1.2394 cov cuab yeej steel sib npaug rau AISI D6?

Yog lawm, 1.2394 (X153CrMoV12) raug txiav txim siabpiv rau AISI D6raws liASTM A681 Cov Khoom Siv Hluav Taws Xob, txawm hais tias muaj qhov sib txawv me ntsis hauv cov tshuaj muaj pes tsawg leeg. Ob leeg muab siab hardness thiab zoo heev hnav tsis kam.

3. Qhov siab tshaj plaws hardness ntawm 1.2394 tom qab kev kho cua sov yog dab tsi?

Tom qab tsim nyog hardening thiab tempering, 1.2394 cov cuab yeej hlau tuaj yeem ncav cuag qhov hardness ntawm60–62 HRC, nyob ntawm seb qhov kev kho cua sov.

| Vim li cas thiaj xaiv SAKYSTEEL: |

Kev ntseeg tau zoo- Peb stainless hlau tuav, kav, coils, thiab flanges yog tsim kom tau raws li thoob ntiaj teb cov qauv xws li ASTM, AISI, EN, thiab JIS.

Kev soj ntsuam nruj- Txhua yam khoom tau dhau los kuaj ultrasonic, tshuaj ntsuam xyuas tshuaj, thiab kev tswj qhov ntev kom ntseeg tau tias muaj kev ua haujlwm siab thiab traceability.

Muaj zog Tshuag & xa khoom sai- Peb tuav cov khoom muag tsis tu ncua ntawm cov khoom tseem ceeb los txhawb kev txiav txim sai thiab kev xa khoom thoob ntiaj teb.

Customized Solutions- Los ntawm kev kho cua sov mus rau qhov chaw tiav, SAKYSTEEL muaj cov kev xaiv tsim kom haum rau koj cov kev xav tau tiag tiag.

Pab neeg tshaj lij- Nrog xyoo dhau los ntawm kev xa tawm, peb pab pawg muag khoom thiab kev txhawb nqa kev ua haujlwm kom muaj kev sib txuas lus zoo, cov lus hais ceev, thiab cov ntaub ntawv tag nrho.

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj): |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev soj ntsuam cuam tshuam

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kuaj

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev Ntsuas Roughness

10. Metallography Experimental Test

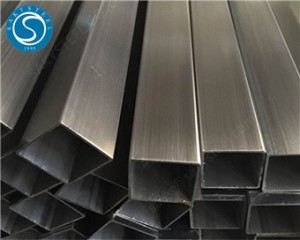

| Custom Processing Peev Xwm: |

-

Kev pabcuam txiav-rau-loj

-

Polishing los yog deg conditioning

-

Slitting rau hauv strips los yog ntawv ci

-

Laser los yog plasma txiav

-

OEM / ODM txais tos

SAKY STEEL txhawb kev txiav kev cai, kev hloov kho saum npoo av, thiab cov kev pabcuam slit-rau-dav rau N7 npib tsib xee daim hlau. Txawm hais tias koj xav tau daim hlau tuab lossis ultra-nyias ntawv, peb xa nrog precision.

| SAKY STEEL Ntim: |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,