1.2394 Insimbi Yensimbi - Insimbi Esebenza Kakhulu Yokusebenza Okubandayo

Incazelo emfushane:

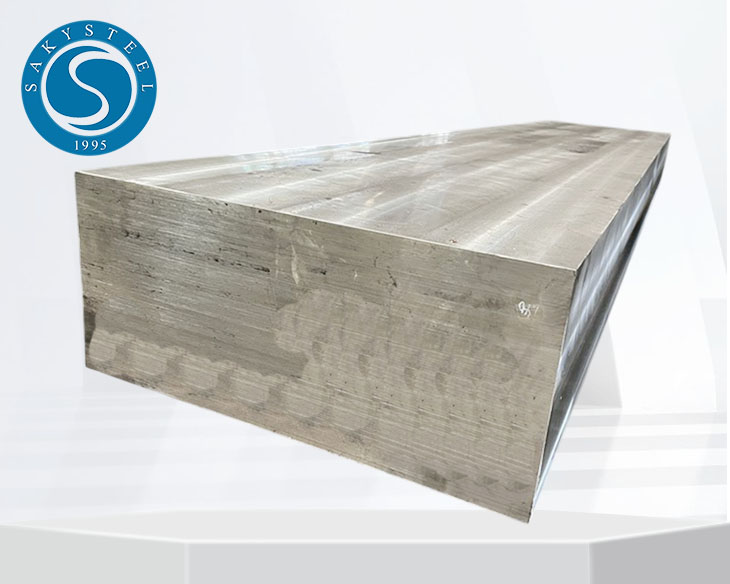

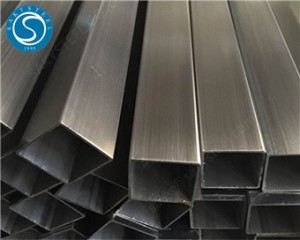

1.2394 insimbi yamathuluziiyinsimbi yensimbi enekhabhoni ephezulu, ephezulu-chromium, kanye ne-tungsten-molybdenum alloyed, eyaziwa ngokungagugi okukhethekile nokuzinza kobukhulu. Isetshenziswa ngokuyinhloko emisebenzini ebandayo edinga ukuqina okuphakeme nokugcinwa komphetho.

Insimbi yamathuluzi ye-DIN 1.2394, eyaziwa nangokuthi i-X153CrMoV12, iyinsimbi enekhabhoni ephezulu, ephezulu ye-chromium ebandayo yokusebenza kwensimbi. Idume ngokumelana nokugqokwa okuvelele nokuzinza okuhle kakhulu kwe-dimensional, le nto ilungele ukufuna izicelo zomsebenzi obandayo njengokuvala, ukubhoboza, namathuluzi okusika. Isetshenziswa ngokujwayelekile ezinhlelweni lapho ubulukhuni bobuso obuphezulu kanye nokuhlanekezela okuncane kuyadingeka.

| Imininingwane ye-1.2394 Tool Steel: |

| Ibanga | 1.2394 |

| Ukubekezelela ukuqina | -0 ukuze +0.1mm |

| Ukucaba | 0.01/100mm |

| Ubuchwepheshe | Okushisiwe Okugoqiwe / Okufojiwe / Okubandayo Okudwetshiwe |

| Ubulukhuni bobuso | I-Ra ≤1.6 noma i-Rz ≤6.3 |

| I-Cold Work Tool Steel 1.2394 Amabanga Alinganayo: |

| IZINGA | AISI | ISO |

| 1.2394 | I-D6 (ingxenye elinganayo) | 160CrMoV12 |

| Ukwakhiwa Kwekhemikhali DIN 1.2394 Insimbi: |

| C | Cr | Mn | Mo | V | Si |

| 1.4-1.55 | 11.0-12.5 | 0.3-0.6 | 0.7-1.0 | 0.3-0.6 | 0.2-0.5 |

| Izici Eziyinhloko I-X153CrMoV12 Tool Steel: |

-

I-Wear Resistance enhle kakhulu: Okuqukethwe kwekhabhoni ephezulu ne-alloy kuqinisekisa ukumelana okuhle kakhulu kokugqokwa kwe-abrasive ezindaweni zokusebenzisa ingcindezi ephezulu.

-

Good Dimensional Ukuzinza: Ilungele amathuluzi anembayo, igcina umumo nosayizi ngemva kokuqina.

-

Amandla Acindezelayo aphezulu: Imelana nemithwalo esindayo kanye nokushaqeka ngaphandle kokuguqulwa.

-

Ukuqina: Inikeza ibhalansi phakathi kokuqina nokuqina, ivimbela ukuqhekeka noma ukuqhekeka.

-

Ukushisa Kwelapheka: Ingenziwa lukhuni ibe ngu-60–62 HRC ngenkathi igcina i-ductility.

| FAQ |

1. Insimbi yensimbi engu-1.2394 isetshenziselwa ini?

1.2394 ngokuyinhloko isetshenziselwa izicelo zomsebenzi obandayo, okuhlanganisa ukufa okungenalutho, izindwani zokusika, amathuluzi okuphungula, nokwenza izibhakela. Ukumelana nokugqokwa kwayo okuphezulu kuyenza ilungele ukusebenza okubandakanya ukucindezelwa okuphindaphindiwe nokuhuzuka.

2. Ingabe insimbi yensimbi engu-1.2394 ilingana ne-AISI D6?

Yebo, i-1.2394 (X153CrMoV12) iyacatshangelwakuqhathaniswa ne-AISI D6ngokuvumelana neI-ASTM A681, nakuba kunomehluko omncane ekwakhekeni kwamakhemikhali. Zombili zinikeza ubulukhuni obuphezulu nokumelana okuhle kakhulu kokugqoka.

3. Yibuphi ubunzima obukhulu be-1.2394 ngemuva kokwelashwa kokushisa?

Ngemuva kokuqina nokuqina okufanele, insimbi yensimbi engu-1.2394 ingafinyelela ubulukhuni be60–62 HRC, kuye ngemingcele yokwelapha ukushisa.

| Kungani Khetha i-SAKYSTEEL : |

Ikhwalithi Ethembekile- Imigoqo yethu yensimbi engagqwali, amapayipi, amakhoyili, nama-flange akhiqizwa ukuze ahlangabezane nezindinganiso zamazwe ngamazwe njenge-ASTM, AISI, EN, ne-JIS.

Ukuhlola Okuqinile– Wonke umkhiqizo wenziwa ukuhlolwa kwe-ultrasonic, ukuhlaziywa kwamakhemikhali, nokulawulwa kobukhulu ukuze kuqinisekiswe ukusebenza okuphezulu nokulandeleka.

Isitoko Esiqinile Nokulethwa Okusheshayo- Sigcina uhlu olujwayelekile lwemikhiqizo ebalulekile ukuze sisekele ama-oda aphuthumayo nokuthunyelwa komhlaba wonke.

Izixazululo ngokwezifiso- Ukusuka ekwelashweni okushisa kuya ekugcineni, i-SAKYSTEEL ikunikeza izinketho ezenziwe ngokwezifiso ukuze zihambisane nezidingo zakho ngqo.

Ithimba Lochwepheshe- Ngesipiliyoni seminyaka yokuthekelisa, ithimba lethu lokuthengisa nelokusekela lobuchwepheshe liqinisekisa ukuxhumana okushelelayo, izingcaphuno ezisheshayo, kanye nensizakalo egcwele yemibhalo.

| Ukuqinisekisa Ikhwalithi Ye-SAKY STEEL (okuhlanganisa kokubili Okubhubhisayo Nokungabhidlizi) : |

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Ukuhlaziywa komthelela

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Ukuhlolwa Okungenele

8. I-Intergranular Corrosion Testing

9. Ukuhlolwa Kokuqina

10. Ukuhlolwa Kokuhlola Kwe-Metallography

| Amandla Okucubungula Ngokwezifiso: |

-

Isevisi yokusika ngosayizi

-

Ukupholisha noma ukufakwa endaweni

-

Ukusika kube yimichilo noma i-foil

-

Ukusika i-Laser noma i-plasma

-

OEM/ODM wamukelekile

I-SAKY STEEL isekela ukusikwa ngokwezifiso, ukulungiswa kokuqedwa kwendawo, kanye nezinsizakalo zokuhlukanisa zibe ububanzi zamapuleti e-nickel e-N7. Kungakhathaliseki ukuthi udinga amapuleti awugqinsi noma ucwecwe oluncane kakhulu, siletha ngokunemba.

| Iphakheji ye-SAKY STEEL'S: |

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,