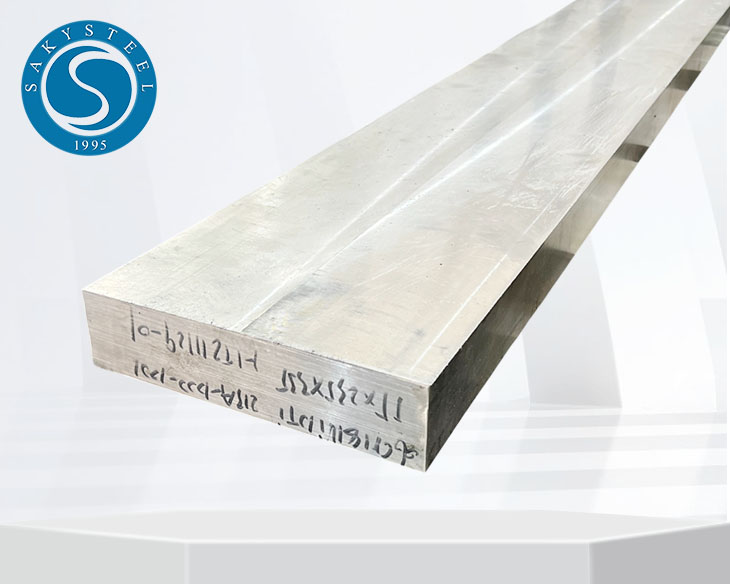

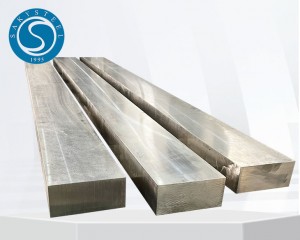

Insimbi Yokusebenza Yamandla Aphezulu Eshisayo 1.2740

Incazelo emfushane:

I-DIN 1.2740 (55NiCrMoV7) iyinsimbi esebenza kakhulu eshisayo esetshenziswa kakhului-forging dies, ama-shear blades ashisayo, i-extrusion tooling, futhiizingxenye zokufa. Ihlanganisa ukuqina okuphezulu nokumelana nokushisa, kulungele amazinga okushisa okusebenza afika ku-500-600°C.

I-1.2740 Tool Steel, eyaziwa nangokuthi i-55NiCrMoV7, iyinsimbi yensimbi ye-nickel-chromium-molybdenum alloyed eshisayo enokuqina okuhle kakhulu, ukuqina, nokumelana nokukhathala okushisayo. Ifaneleka ngokukhethekile kumathuluzi okwakha ashisayo adinga amandla aphezulu kanye nokumelana nokushaqeka okushisayo.

| Imininingwane ye-1.2740 Tool Steel: |

| Ibanga | 1.2740 |

| Ukubekezelelana kokuqina | -0 ukuze +0.1mm |

| Ukucaba | 0.01/100mm |

| Ubuchwepheshe | Umsebenzi oshisayo / owakhiwe / obandayo |

| Ubulukhuni bobuso | I-Ra ≤1.6 noma i-Rz ≤6.3 |

| I-Chemical Composition 55NiCrMoV7 steel: |

| C | Cr | Si | P | Mn | Ni | Mo | V | S |

| 0.24-0.32 | 0.6-0.9 | 0.3-0.5 | 0.03 | 0.2-0.4 | 2.3-2.6 | 0.5-0.7 | 0.25-0.32 | 0.03 |

| Izici ezibalulekile I-DIN 1.2740 ingxubevange yensimbi: |

-

Ukuqina okuphezulu- ukumelana okuhle kakhulu komthelela nokuqhekeka

-

Ukumelana nokukhathala okushisayo- ilungele imijikelezo yokushisa/yokupholisa ephindaphindiwe

-

Ukuqina okuhle- ilungele izingxenye ezinkulu eziphambanayo

-

Ukuzinza kwe-Tempering– igcina ubulukhuni emazingeni okushisa aphezulu

-

Ukwelashwa okuhle kakhulu kokushisa- ifinyelela ku-48–52 HRC ngemuva kokucisha kanye nokushisa

-

Ukusebenza okulingene- kulula ukuwenza umshini usesimweni esishubile

| FAQ |

Q1: Iyini insimbi yensimbi engu-1.2740 esetshenziselwa?

A: Isetshenziswa kakhuluukuganga okushisayo kuyafa, izibambi, ama-shear blades ashisayo, namathuluzi angaphansi komthelela omkhulu nemijikelezo yezinga lokushisa.

Q2: Ingabe i-1.2740 ilingana ne-AISI L6?

A: Ifana ngokwengxenye ne-AISI L6 ekubunjweni kwayo, kodwaI-DIN 1.2740 inikezela ngokuqukethwe okuphezulu kwe-nickelnokusebenza okungcono kwezinga lokushisa eliphezulu.

Q3: Buyini ubulukhuni obujwayelekile ngemva kokwelashwa kokushisa?

A: Ngemuva kokuqina nokuthambisa,I-1.2740 ingafinyelela ku-48–52 HRC, ilungele amathuluzi okusebenza ashisayo asindayo.

Q4: Yimaphi amafomu omkhiqizo atholakalayo?

A: Sinikezaimigoqo eyindilinga, izingcwecwe eziyisicaba, amabhlogo, kanye nezingxenye ezenziwe ngokwezifiso ngomdwebo wakho ngamunye.

| Kungani Khetha i-SAKYSTEEL : |

Ikhwalithi Ethembekile- Imigoqo yethu yensimbi engagqwali, amapayipi, amakhoyili, nama-flange akhiqizwa ukuze ahlangabezane nezindinganiso zamazwe ngamazwe njenge-ASTM, AISI, EN, ne-JIS.

Ukuhlola Okuqinile– Wonke umkhiqizo wenziwa ukuhlolwa kwe-ultrasonic, ukuhlaziywa kwamakhemikhali, nokulawulwa kobukhulu ukuze kuqinisekiswe ukusebenza okuphezulu nokulandeleka.

Isitoko Esiqinile Nokulethwa Okusheshayo- Sigcina uhlu olujwayelekile lwemikhiqizo ebalulekile ukuze sisekele ama-oda aphuthumayo nokuthunyelwa komhlaba wonke.

Izixazululo ngokwezifiso- Ukusuka ekwelashweni okushisa kuya ekugcineni, i-SAKYSTEEL ikunikeza izinketho ezenziwe ngokwezifiso ukuze zihambisane nezidingo zakho ngqo.

Ithimba Lochwepheshe- Ngesipiliyoni seminyaka yokuthekelisa, ithimba lethu lokuthengisa nelokusekela lobuchwepheshe liqinisekisa ukuxhumana okushelelayo, izingcaphuno ezisheshayo, kanye nensizakalo egcwele yemibhalo.

| Ukuqinisekisa Ikhwalithi Ye-SAKY STEEL (okuhlanganisa kokubili Okubhubhisayo Nokungabhidlizi) : |

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Ukuhlaziywa komthelela

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Ukuhlolwa Okungenele

8. I-Intergranular Corrosion Testing

9. Ukuhlolwa Kokuqina

10. Ukuhlolwa Kokuhlola Kwe-Metallography

| Amandla Okucubungula Ngokwezifiso: |

-

Isevisi yokusika ngosayizi

-

Ukupholisha noma ukufakwa endaweni

-

Ukusika kube yimichilo noma i-foil

-

Ukusika i-Laser noma i-plasma

-

OEM/ODM wamukelekile

I-SAKY STEEL isekela ukusikwa ngokwezifiso, ukulungiswa kokuqedwa kwendawo, kanye nezinsizakalo zokuhlukanisa zibe ububanzi zamapuleti e-nickel e-N7. Kungakhathaliseki ukuthi udinga amapuleti awugqinsi noma ucwecwe oluncane kakhulu, siletha ngokunemba.

| Iphakheji ye-SAKY STEEL'S: |

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,