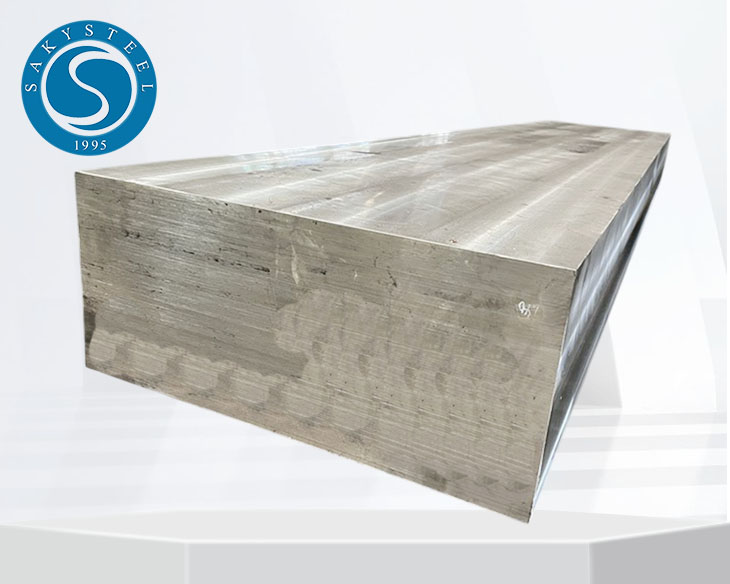

1.2394 Tool Steel - High-Performance Cold Work Alloy Steel

Tlhaloso e Khutšoanyane:

1.2394 lisebelisoa tsa tšepeke tšepe e nang le k'habone e phahameng, chromium e phahameng, le tungsten-molybdenum alloyed tool, e tsejoang ka ho hanyetsa ha eona ka mokhoa o ikhethang le botsitso ba sebopeho. E sebelisoa haholo-holo lits'ebetsong tse batang tsa mosebetsi tse hlokang boima bo phahameng le ho boloka moeli.

DIN 1.2394 tool steel, eo hape e tsejoang e le X153CrMoV12, ke tšepe e nang le khabone e phahameng, e nang le chromium e batang haholo. E tsebahala ka ho hanyetsa ho apara ka mokhoa o tsotehang le botsitso bo botle ba sebopeho, thepa ena e loketse ho batla likopo tse batang tse kang ho koala, ho phunya le ho itšeha lisebelisoa. Hangata e sebelisoa lits'ebetsong moo ho hlokahalang hore ho be le boima bo phahameng ba holim'a metsi le ho sotha ho fokolang.

| Litlhaloso tsa 1.2394 Tool Steel: |

| Kereiti | 1.2394 |

| Mamello ea botenya | -0 ho + 0.1mm |

| Bophatlalatsi | 0.01/100mm |

| Thekenoloji | E kolobisitsoeng ka ho chesa / E foriloe / E Ratehileng |

| Bokhoakhoa ba bokaholimo | Ra ≤1.6 kapa Rz ≤6.3 |

| Cold Work Tool Steel 1.2394 Mephato e Tšoanang: |

| TS'ELISO | AISI | ISO |

| 1.2394 | D6 (karolelano e lekanang) | 160CrMoV12 |

| Sebopeho sa Lik'hemik'hale DIN 1.2394 Tšepe: |

| C | Cr | Mn | Mo | V | Si |

| 1.4-1,55 | 11.0-12.5 | 0.3-0.6 | 0.7-1.0 | 0.3-0.6 | 0.2-0.5 |

| Lintlha tsa bohlokoa X153CrMoV12 Tool Steel: |

-

Excellent Wear Resistance: Likahare tse phahameng tsa carbon le alloy li netefatsa hore ho na le khanyetso e ntle ka ho fetisisa ea abrasive libakeng tsa lisebelisoa tse phahameng tsa khatello.

-

Botsitso bo Botle ba Dimensional: E loketse lisebelisoa tse nepahetseng, ho boloka sebopeho le boholo ka mor'a ho thatafala.

-

Matla a Phahamisang a Phahameng: E mamella meroalo e boima le lintho tse tšosang ntle le deformation.

-

Ho thatafala: E fana ka ho leka-lekana pakeng tsa ho thatafala le ho tiea, ho thibela ho phunyeha kapa ho phunyeha.

-

Mocheso o ka Phekoleha: E ka thatafatsoa ho 60–62 HRC ha e ntse e boloka ductility.

| LBH |

1. 1.2394 sesebelisoa tšepe e sebelisetsoa eng?

1.2394 e sebelisoa haholo-holo bakeng sa lits'ebetso tse batang tsa mosebetsi, ho kenyelletsa le li-blanking dies, li-blades tsa ho itšeha, lisebelisoa tsa ho kuta, le ho etsa litebele. Ho hanyetsa ha eona ho phahameng ho etsa hore e be e loketseng bakeng sa ts'ebetso e kenyelletsang khatello ea maikutlo khafetsa le ho abrasion.

2. Na 1.2394 sesebelisoa sa tšepe se lekana le AISI D6?

E, 1.2394 (X153CrMoV12) e nkoae bapisoa le AISI D6ho latelaASTM A681, le hoja ho na le phapang e fokolang ea lik'hemik'hale. Ka bobeli li fana ka boima bo phahameng le khanyetso e ntle ea ho apara.

3. Ke boima bofe bo boholo ba 1.2394 ka mor'a phekolo ea mocheso?

Ka mor'a hore ho thatafatsoe hantle le ho halefa, 1.2394 sesebelisoa sa tšepe se ka finyella boima ba60–62 HRC, ho itšetlehile ka litekanyetso tsa phekolo ea mocheso.

| Hobaneng u Khetha SAKYSTEEL : |

Boleng bo Tšepahalang- Mekoallo ea rona ea tšepe e sa hloekang, liphaephe, li-coil le li-flange li etsoa ho finyella litekanyetso tsa machaba tse kang ASTM, AISI, EN, le JIS.

Tlhahlobo e tiileng- Sehlahisoa se seng le se seng se etsoa tlhahlobo ea ultrasonic, tlhahlobo ea lik'hemik'hale, le taolo ea boholo ho netefatsa ts'ebetso e phahameng le ts'ebetso.

Setoko se Matla le Phano e potlakileng- Re boloka lethathamo la kamehla la lihlahisoa tsa bohlokoa ho ts'ehetsa liodara tse potlakileng le thomello ea lefats'e.

Customized Solutions- Ho tloha kalafong ea mocheso ho fihlela qetellong, SAKYSTEEL e fana ka likhetho tse entsoeng ka mokhoa o ikhethileng ho lumellana le litlhoko tsa hau hantle.

Sehlopha sa Litsebi- Ka lilemo tsa boiphihlelo ba kantle ho naha, sehlopha sa rona sa thekiso le tšehetso ea tekheniki se netefatsa puisano e bonolo, mantsoe a qotsitsoeng kapele le tšebeletso e felletseng ea litokomane.

| Netefatso ea Boleng ea SAKY STEEL (ho kenyeletsoa tse senyang le tse sa senyeheng) : |

1. Teko ea Visual Dimension

2. Tlhahlobo ea mochine joalo ka tensile, Elongation le phokotso ea sebaka.

3. Tlhahlobo ea phello

4. Tlhahlobo ea tlhahlobo ea lik'hemik'hale

5. Teko ea boima

6. Teko ea tšireletso ea likoti

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Teko ea ho Roughness

10. Metallography Teko ea Teko

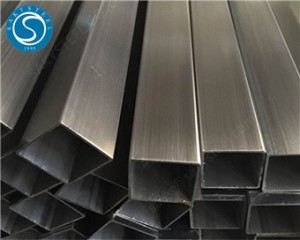

| Tsebo e Tloaelehileng ea ho sebetsa: |

-

Tšebeletso e fokolang ka boholo

-

Ho benyang kapa boemo ba bokahodimo

-

Ho arola ka lihlopha kapa foil

-

Ho itšeha ka laser kapa plasma

-

OEM / ODM amohela

SAKY STEEL e ts'ehetsa mokhoa oa ho itšeha, litokiso tsa ho qetela, le lits'ebeletso tsa ho petsoha ho isa bophara bakeng sa lipoleiti tsa nickel tsa N7. Hore na o hloka lipoleiti tse teteaneng kapa foil e tšesaane haholo, re fana ka eona ka nepo.

| Sephutheloana sa SAKY STEEL'S: |

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,