N4 N6 Nickel Bar | Ntshiab Nickel Qws ASTM B160 Chaw tsim tshuaj paus

Lus piav qhia luv luv:

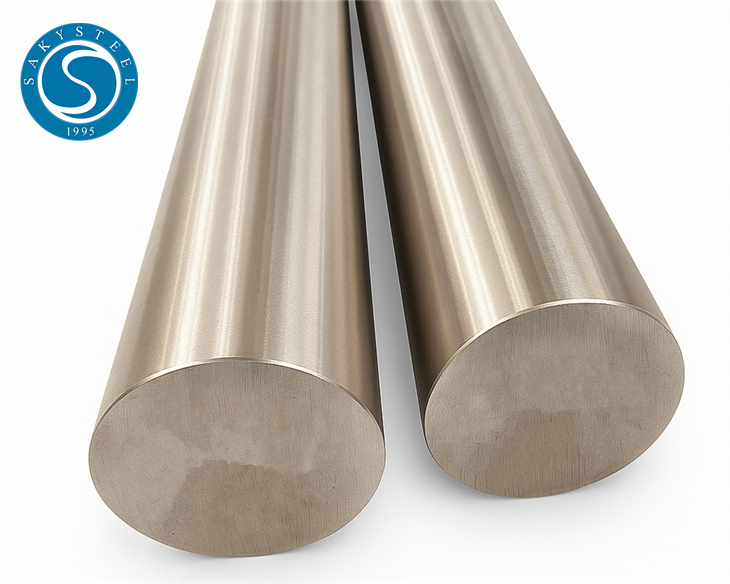

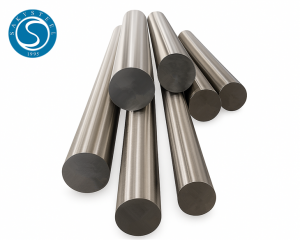

SAKY STEEL muaj N4 thiab N6 npib tsib xee tuav, tsim rau ASTM B160 tus qauv. Cov ntshiab nickel rods feature tshwj xeeb corrosion kuj, hluav taws xob conductivity, thiab zoo heev mechanical zog, ua rau lawv zoo tagnrho rau kev thov kev lag luam.

SAKY STEEL khoom siv high-purity N4 thiab N6 npib tsib xee tuav, tsim ua raws li ASTM B160 thiab GB / T 2054 tus qauv. Cov ntshiab nickel rods muaj kev tiv thaiv corrosion zoo heev, superior hluav taws xob thiab thermal conductivity, thiab zoo heev mechanical zog. N6 qib, nrog cov ntsiab lus npib tsib xee ntawm ≥99.9%, tshwj xeeb tshaj yog tsim nyog rau kev thov siv tshuaj lom neeg thiab hluav taws xob. Muaj nyob rau hauv ntau qhov ntau thiab tsawg thiab qhov chaw tiav, peb cov N4 / N6 nickel tuav tau dav siv hauv kev ua tshuaj lom neeg, marine, electroplating, thiab roj teeb kev lag luam. Kev cai ntev, txiav, thiab machining cov kev pabcuam muaj nyob rau ntawm qhov kev thov.

| Specifications ntawm N4 N6 Nickel Bar: |

| Specifications | GB/T 2054 |

| Qib | N7(N02200),N4,N5,N6 |

| Ntev | 1000mm - 6000mm los yog raws li kev thov |

| Txoj kab uas hla | 10mm-200mm (kev cai muaj) |

| Technology | Kub Rolled / Forged / Cold Drawn |

| Surface tiav | Bright, Peeled, Polished, Tig, Pickled |

| Daim ntawv | Hloov, Square, tiaj tus, hexagonal |

Qib thiab cov qauv siv tau

| Qib | Phaj Standard | Sawb Standard | Tube Standard | Qws Standard | Hlau Standard | Forging Standard |

|---|---|---|---|---|---|---|

| N4 | GB/T2054-2013NB/T47046-2015 | GB/T2072-2007 | GB/T2882-2013NB/T47047-2015 | GB/T4435-2010 | GB/T21653-2008 | NB/T47028-2012 |

| N5 (N02201) | GB / T2054-2013ASTM B162 | GB / T2072-2007ASTM B162 | GB / T2882-2013 ASTM B161 | GB / T4435-2010ASTM B160 | GB/T26030-2010 | |

| N6 | GB/T2054-2013 | GB/T2072-2007 | GB/T2882-2013 | GB/T4435-2010 | ||

| N7 (N02200) | GB / T2054-2013ASTM B162 | GB / T2072-2007ASTM B162 | GB / T2882-2013 ASTM B161 | GB / T4435-2010ASTM B160 | GB/T26030-2010 | |

| N8 | GB/T2054-2013 | GB/T2072-2007 | GB/T2882-2013 | GB/T4435-2010 | ||

| DN | GB/T2054-2013 | GB/T2072-2007 | GB/T2882-2013 |

| N02200 Nickel Equivalent Qib: |

| Thawj Lub Npe | Alternative English Names | Txheem / Lus Cim |

|---|---|---|

| N4 Nickel Bar | Nickel 200 Bar | Sib npaug rau UNS N02200, low-carbon nickel |

| N6 Nickel Bar | Nickel 201 Bar muaj | Sib npaug rau UNS N02201, ultra-low carbon |

| Ntshiab Nickel Bar | - | Common lub sij hawm kev lag luam |

| High Purity Nickel Qws | - | Feem ntau siv hauv hluav taws xob, siv roj teeb |

| Nickel Round Bar | - | Raws li cov duab |

| Nickel Hlau Bar | - | Piav qhia txog lub hauv paus hlau daim ntawv |

| Kev lag luam Ntshiab Nickel Qws | - | Hais txog cov khoom uas tsis muaj nickel |

| Nickel Alloy Bar (nruab nrab) | - | qeb dav; tsis hais txog N4/N6 |

| ASTM B160 Nickel Bar 1 | - | ASTM tus qauv tsim |

| GB/T 2054 Nickel qws | - | Suav teb tus qauv |

| DIN 17752 Nickel Bar | - | German txuj |

| UNS N02200 Bar | N4 Nickel Bar, Nickel 200 Bar | UNS tus lej rau N4 |

| UNS N02201 Bar | N6 Nickel Bar, Nickel 201 Bar | UNS tus lej rau N6 |

| Tshuaj muaj pes tsawg leeg N7 Ntshiab Nickel Sheet: |

| Qib | Tsis muaj (%) | C (%) | Fe (%) | S (%) | Si (%) | Cu (%) |

|---|---|---|---|---|---|---|

| N4 | ≥99.5 | ≤ 0.10 | ≤ 0.10 | ≤ 0.01 | ≤ 0.10 | ≤ 0.20 |

| N6 | ≥99.9 | ≤ 0.05 | ≤ 0.05 | ≤ 0.005 | ≤ 0.05 | ≤ 0.10 |

Mechanical Properties ntawm Nickel Bars

| Qib | Qhov xwm txheej | Txoj kab uas hla (mm) | Tensile zog Rm (MPa) | Elongation A (%) |

|---|---|---|---|---|

| N4 | Y | 3–20 | 590 ua | 5 |

| N4 | Y | > 20–30 | 540 | 6 |

| N5 | Y | > 30–65 | 510 | 9 |

| N6 | M | 3–30 | 380 | 34 |

| N7 | M | > 30–65 | 345 | 34 |

| N8 | R | 32–60 : kuv | 345 | 25 |

| N8 | R | > 60–254 | 345 | 20 |

| Daim ntawv thov ntawm UNS N02200 Nickel Plate: |

-

-

Kev ua tshuaj lom neeg: reactors, evaporators, piping systems

-

Electronics: roj teeb tabs, electrodes, shielding

-

Kev lag luam marine: Corrosion-resistant structural qhov chaw

-

Electroplating thiab nqus cov khoom

-

Cov khoom siv kho mob thiab kuaj

-

| Vim li cas thiaj xaiv SAKYSTEEL: |

Kev ntseeg tau zoo- Peb stainless hlau tuav, kav, coils, thiab flanges yog tsim kom tau raws li thoob ntiaj teb cov qauv xws li ASTM, AISI, EN, thiab JIS.

Kev soj ntsuam nruj- Txhua yam khoom tau dhau los kuaj ultrasonic, tshuaj ntsuam xyuas tshuaj, thiab kev tswj qhov ntev kom ntseeg tau tias muaj kev ua haujlwm siab thiab traceability.

Muaj zog Tshuag & xa khoom sai- Peb tuav cov khoom muag tsis tu ncua ntawm cov khoom tseem ceeb los txhawb kev txiav txim sai thiab kev xa khoom thoob ntiaj teb.

Customized Solutions- Los ntawm kev kho cua sov mus rau qhov chaw tiav, SAKYSTEEL muaj cov kev xaiv tsim kom haum rau koj cov kev xav tau tiag tiag.

Pab neeg tshaj lij- Nrog xyoo dhau los ntawm kev xa tawm, peb pab pawg muag khoom thiab kev txhawb nqa kev ua haujlwm kom muaj kev sib txuas lus zoo, cov lus hais ceev, thiab cov ntaub ntawv tag nrho.

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj): |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev soj ntsuam cuam tshuam

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kev xeem

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev Ntsuas Roughness

10. Metallography Experimental Test

| Custom Processing Peev Xwm: |

-

Kev pabcuam txiav-rau-loj

-

Polishing los yog deg conditioning

-

Slitting rau hauv strips los yog ntawv ci

-

Laser los yog plasma txiav

-

OEM / ODM txais tos

SAKY STEEL txhawb kev txiav kev cai, kev hloov kho saum npoo av, thiab cov kev pabcuam slit-rau-dav rau N7 npib tsib xee daim hlau. Txawm hais tias koj xav tau daim hlau tuab lossis ultra-nyias ntawv, peb xa nrog precision.

| SAKY STEEL Ntim: |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,