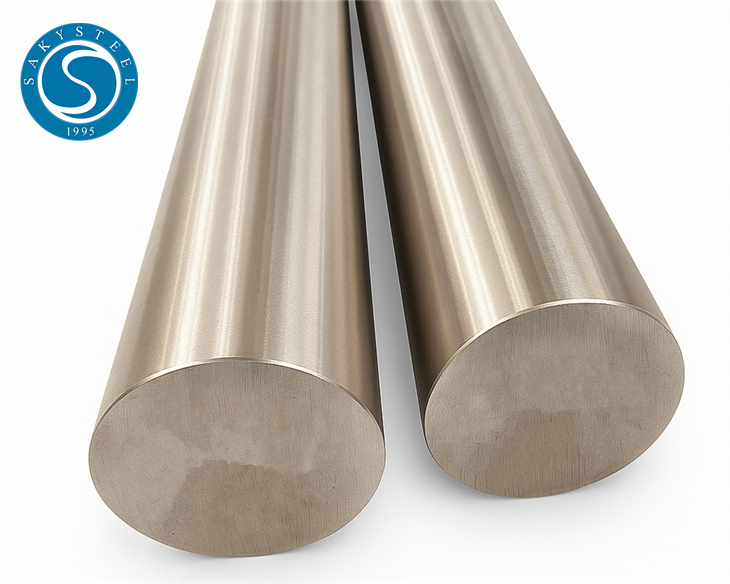

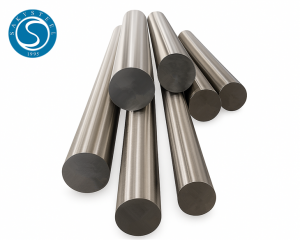

N4 N6 Nickel Bar | Pure Nickel Rod ASTM B160 Manufacturer

Short Description:

SAKY STEEL offers N4 and N6 nickel bars, manufactured to ASTM B160 standards. These pure nickel rods feature exceptional corrosion resistance, high electrical conductivity, and excellent mechanical strength, making them ideal for demanding industrial applications.

SAKY STEEL supplies high-purity N4 and N6 nickel bars, manufactured in compliance with ASTM B160 and GB/T 2054 standards. These pure nickel rods offer excellent corrosion resistance, superior electrical and thermal conductivity, and outstanding mechanical strength. The N6 grade, with a nickel content of ≥99.9%, is especially suitable for demanding chemical and electronic applications. Available in various sizes and surface finishes, our N4/N6 nickel bars are widely used in the chemical processing, marine, electroplating, and battery industries. Custom lengths, cutting, and machining services are available upon request.

| Specifications of N4 N6 Nickel Bar: |

| Specifications | GB/T 2054 |

| Grade | N7(N02200),N4,N5,N6 |

| Length | 1000 mm – 6000 mm or as requested |

| Diameter Range | 10 mm – 200 mm (custom available) |

| Technology | Hot Rolled / Forged / Cold Drawn |

| Surface Finish | Bright, Peeled, Polished, Turned, Pickled |

| Form | Round, Square, Flat, Hexagonal |

Grades and Applicable Standards

| Grade | Plate Standard | Strip Standard | Tube Standard | Rod Standard | Wire Standard | Forging Standard |

|---|---|---|---|---|---|---|

| N4 | GB/T2054-2013NB/T47046-2015 | GB/T2072-2007 | GB/T2882-2013NB/T47047-2015 | GB/T4435-2010 | GB/T21653-2008 | NB/T47028-2012 |

| N5 (N02201) | GB/T2054-2013ASTM B162 | GB/T2072-2007ASTM B162 | GB/T2882-2013ASTM B161 | GB/T4435-2010ASTM B160 | GB/T26030-2010 | |

| N6 | GB/T2054-2013 | GB/T2072-2007 | GB/T2882-2013 | GB/T4435-2010 | ||

| N7 (N02200) | GB/T2054-2013ASTM B162 | GB/T2072-2007ASTM B162 | GB/T2882-2013ASTM B161 | GB/T4435-2010ASTM B160 | GB/T26030-2010 | |

| N8 | GB/T2054-2013 | GB/T2072-2007 | GB/T2882-2013 | GB/T4435-2010 | ||

| DN | GB/T2054-2013 | GB/T2072-2007 | GB/T2882-2013 |

| N02200 Nickel Equivalent Grades: |

| Primary Name | Alternative English Names | Standard / Notes |

|---|---|---|

| N4 Nickel Bar | Nickel 200 Bar | Equivalent to UNS N02200, low-carbon nickel |

| N6 Nickel Bar | Nickel 201 Bar | Equivalent to UNS N02201, ultra-low carbon |

| Pure Nickel Bar | – | Common industry term |

| High Purity Nickel Rod | – | Often used in electronics, battery applications |

| Nickel Round Bar | – | Based on shape |

| Nickel Metal Bar | – | Describes base metal form |

| Commercially Pure Nickel Rod | – | Refers to unalloyed nickel products |

| Nickel Alloy Bar (broad) | – | General category; not specific to N4/N6 |

| ASTM B160 Nickel Bar | – | ASTM standard designation |

| GB/T 2054 Nickel Rod | – | Chinese national standard |

| DIN 17752 Nickel Bar | – | German standard |

| UNS N02200 Bar | N4 Nickel Bar, Nickel 200 Bar | Official UNS number for N4 |

| UNS N02201 Bar | N6 Nickel Bar, Nickel 201 Bar | Official UNS number for N6 |

| Chemical Composition N7 Pure Nickel Sheet: |

| Grade | Ni (%) | C (%) | Fe (%) | S (%) | Si (%) | Cu (%) |

|---|---|---|---|---|---|---|

| N4 | ≥99.5 | ≤0.10 | ≤0.10 | ≤0.01 | ≤0.10 | ≤0.20 |

| N6 | ≥99.9 | ≤0.05 | ≤0.05 | ≤0.005 | ≤0.05 | ≤0.10 |

Mechanical Properties of Nickel Bars

| Grade | Condition | Diameter (mm) | Tensile Strength Rm (MPa) | Elongation A (%) |

|---|---|---|---|---|

| N4 | Y | 3–20 | 590 | 5 |

| N4 | Y | >20–30 | 540 | 6 |

| N5 | Y | >30–65 | 510 | 9 |

| N6 | M | 3–30 | 380 | 34 |

| N7 | M | >30–65 | 345 | 34 |

| N8 | R | 32–60 | 345 | 25 |

| N8 | R | >60–254 | 345 | 20 |

| Applications of UNS N02200 Nickel Plate: |

-

-

Chemical processing: reactors, evaporators, piping systems

-

Electronics: battery tabs, electrodes, shielding

-

Marine industry: corrosion-resistant structural parts

-

Electroplating and vacuum components

-

Medical and laboratory equipment

-

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| Custom Processing Capabilities: |

-

Cut-to-size service

-

Polishing or surface conditioning

-

Slitting into strips or foil

-

Laser or plasma cutting

-

OEM/ODM welcome

SAKY STEEL supports custom cutting, surface finish adjustments, and slit-to-width services for N7 nickel plates. Whether you need thick plates or ultra-thin foil, we deliver with precision.

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,