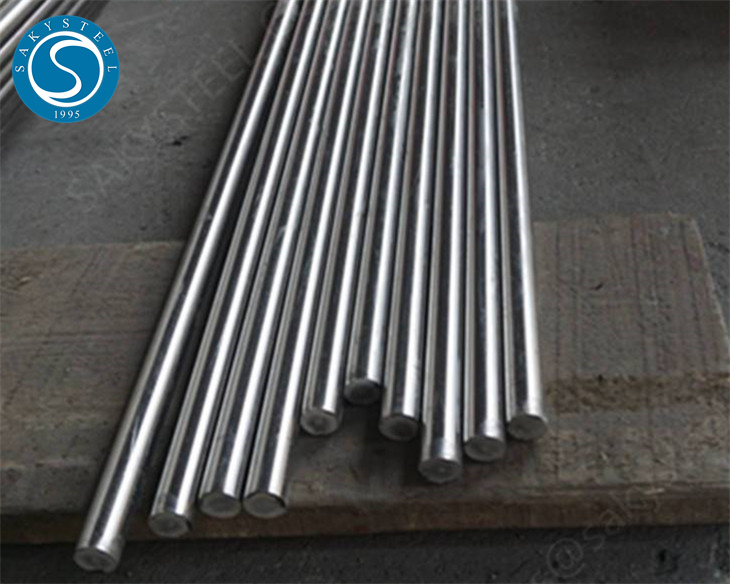

1.4923 X22CrMoV12-1 Round Bars

Lus piav qhia luv luv:

Tshawb nrhiav 1.4923 X22CrMoV12-1 round bar zoo tagnrho rau kev siv kub kub xws li turbines thiab boilers. Tshawb cov khoom, qhov ntev, thiab cov kev xaiv kho kom haum.

1.4923 X22CrMoV12-1 Round Bars:

1.4923 (X22CrMoV12-1) puag ncig tuav yog lub zog siab, kub-resistant alloy steel tuav tsim rau kev siv hauv qhov chaw huab cua. Nrog rau kev ua haujlwm zoo rau qhov kub thiab txias thiab oxidation, lawv feem ntau yog siv rau hauv turbine hniav, boiler Cheebtsam, thiab high-pressure piping systems. Cov khoom siv no muaj qhov sib npaug ntawm chromium, molybdenum, thiab vanadium, ua kom cov khoom siv zoo tshaj plaws, suav nrog lub zog tensile siab, toughness, thiab durability, txawm tias kub siab txog 600 ° C. Qhov zoo tshaj plaws rau kev lag luam uas yuav tsum tau muaj kev ntseeg siab nyob rau hauv thermal stress, 1.4923 round bars raws li nruj DIN thiab EN cov qauv, kom ntseeg tau zoo ib yam thiab kev ua tau zoo.

Specifications ntawm X22CrMoV12-1 Round Bar:

| Ultrasonic Test Standard | DIN EN 10269 |

| Qib | 1.4923, X22CrMoV12-1 |

| Ntev | 1-12M & Ntev Ntev |

| Nto tiav | Dub, Dawb |

| Daim ntawv | Hloov |

| Xaus | Plain End, Beveled End |

| Mill Test Certificate | EN 10204 3.1 lossis EN 10204 3.2 |

1.4923 Round Bar Sib npaug Qib:

| DIN | WERKSTOFF NR. | AISI |

| X22CrMoV12-1 | 1.4923 ib | X 22 |

X22CrMoV12-1 Round Bar Chemical Composition:

| C | Mn | P | S | Si | Cr | Ni | Mo |

| 0.18-0.24 dr hab | 0.4-0.9 hli | 0.025 ib | 0.015 ib | 0.50 ib | 11.0-12.5 Nws | 0.3-0.8 hli | 0.8-1.2 hli |

1.4923 Steel Bars Mechanical zog:

| Khoom siv | Yield zog (Mpa) | Tensile zog (Mpa) | Hardness |

| 1.4923 ib | 600 | 750-950 : kuv | 240-310 HWB |

Cov yam ntxwv ntawm 1.4923 Steel (X22CrMoV12-1):

1.Excellent Thaum tshav kub kub Resistance:1.4923 steel tuav ruaj khov khoom siv nyob rau hauv qhov kub thiab txias (txog 600 ° C), ua rau nws zoo tagnrho rau kev siv mus sij hawm ntev nyob rau hauv high-temperature thiab high-pressure ib puag ncig.

2.High Strength thiab Toughness:Nrog lub zog tensile siab (750-950 MPa) thiab tshwj xeeb toughness, cov hlau no ua kom ntseeg tau tias kev ua tau zoo nyob rau hauv thermal thiab mechanical stress.

3.Oxidation thiab Corrosion Resistance:Nws cov alloy muaj pes tsawg leeg, featuring siab chromium (10.5-12.5%) thiab molybdenum (0.9-1.2%), muab kev tiv thaiv zoo heev rau oxidation thiab corrosion nyob rau hauv siab kub.

4.Kev kho cua sov zoo:1.4923 steel tuaj yeem ua kom zoo dua los ntawm kev quenching thiab tempering, txhim khu nws hardness, lub zog, thiab toughness kom tau raws li ntau yam engineering xav tau.

5.Wide Industrial Applications:Feem ntau siv nyob rau hauv cov khoom raug rau qhov kub thiab txias, xws li: Chav turbine hniav, Boiler Cheebtsam, Thaum tshav kub kub exchangers, high-pressure piping, ua raws li International Standards.

Vim li cas thiaj xaiv peb?

•Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

•Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

•Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

•Peb lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

•Muab SGS TUV daim ntawv qhia.

•Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

•Muab kev pabcuam ib-nres.

1.4923 Round Bar Ntim:

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,