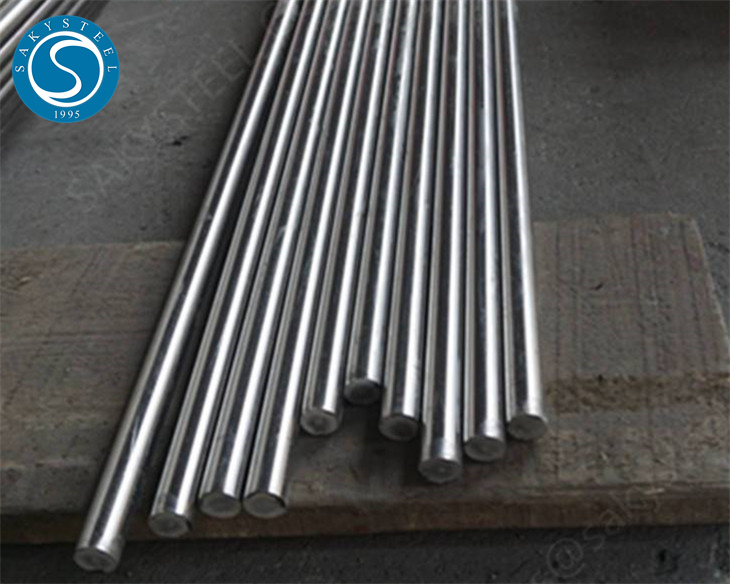

1.4923 X22CrMoV12-1 Round Bars

Tsanangudzo Pfupi

Ziva 1.4923 X22CrMoV12-1 mabhawa ekutenderera akanakira kutonhora kwepamusoro-soro senge turbines uye boilers. Ongorora zvivakwa, hukuru, uye sarudzo dzekugadzirisa.

1.4923 X22CrMoV12-1 Round Bars:

1.4923 (X22CrMoV12-1) mbariro dzakatenderedzwa dzakakwirira-simba, dzisingasviki kupisa alloy simbi simbi dzakagadzirirwa kushandiswa munzvimbo dzakanyanyisa. Nekupokana kwakanyanya kune tembiricha yakakwira uye oxidation, ivo vanowanzoshandiswa mu turbine blades, boiler components, uye high-pressure piping systems. Ichi chinyorwa chinopa kuumbwa kwakaringana kwechromium, molybdenum, uye vanadium, kuve nechokwadi chemhando yepamusoro michina, kusanganisira kusimba kwakanyanya, kusimba, uye kusimba, kunyangwe kune tembiricha yakakwira kusvika 600 ° C. Yakanakira maindasitiri anoda kuvimbika pasi pekunetseka kwekupisa, 1.4923 mabhawa ekutenderera anosangana akaomesesa DIN uye EN zviyero, kuve nechokwadi chakaenderana uye kuita.

Zvinotsanangurwa zveX22CrMoV12-1 Round Bar:

| Ultrasonic Test Standard | DIN EN 10269 |

| Giredhi | 1.4923, X22CrMoV12-1 |

| Urefu | 1-12M & Inodiwa Hurefu |

| Surface Finish | Dema, Bright |

| Form | Round |

| End | Plain End, Beveled End |

| Mill Test Certificate | EN 10204 3.1 kana EN 10204 3.2 |

1.4923 Round Bar Yakaenzana Magiredhi:

| DIN | WERKSTOFF NR. | AISI |

| X22CrMoV12-1 | 1.4923 | X22 |

X22CrMoV12-1 Round Bar Chemical Kuumbwa:

| C | Mn | P | S | Si | Cr | Ni | Mo |

| 0.18-0.24 | 0.4-0.9 | 0.025 | 0.015 | 0.50 | 11.0-12.5 | 0.3-0.8 | 0.8-1.2 |

1.4923 Steel Bars Mechanical properties :

| Material | Goho Simba (Mpa) | Tensile Strength (Mpa) | Kuoma |

| 1.4923 | 600 | 750-950 | 240-310 HBW |

Zvimiro zve1.4923 Steel (X22CrMoV12-1):

1.Excellent Heat Resistance:1.4923 simbi inochengetedza yakagadzikana mechanical properties pasi pekushisa kwepamusoro (kusvika ku600 ° C), ichiita kuti ive yakakodzera kushandiswa kwenguva refu mumhepo yepamusoro-soro uye yepamusoro-soro.

2.Kusimba Kwepamusoro uye Kusimba:Iine simba rakanyanya kusimba (750-950 MPa) uye kusimba kwakasiyana, iyi simbi inovimbisa kushanda kwakavimbika pasi pekupisa uye kushushikana kwemagetsi.

3.Oxidation uye Corrosion Resistance:Yayo alloy kuumbwa, ine yakakwira chromium (10.5-12.5%) uye molybdenum (0.9-1.2%), inopa yakanakisa kuramba kune oxidation uye ngura mumamiriro ekushisa akakwira.

4.Good Heat Treatability:1.4923 simbi inogona kugadziridzwa kuburikidza nekudzima nekudzikamisa, ichiwedzera kuoma kwayo, simba, uye kuomarara kuti isangane neakasiyana mainjiniya zvinodiwa.

5.Wide Industrial Applications:Inowanzo shandiswa muzvikamu zvakafumurwa kune tembiricha yakakwira uye kudzvanywa, senge:Steam turbine blades,Boiler components,Heat exchangers,High-pressure piping,Kutevedzera International Standards.

Sei Sarudza isu?

•Iwe unogona kuwana iyo yakakwana zvinhu zvinoenderana nezvinodiwa zvako pamutengo unogoneka.

•Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekuendesa gonhi kumusuwo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

•Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pachitupa chebvunzo kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

•Isu tinovimbisa kupa mhinduro mukati me24hours (kazhinji muawa imwe chete)

•Ipa SGS TUV chirevo.

•Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

•Ipa imwe-stop service.

1.4923 Round Bar Packing:

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,