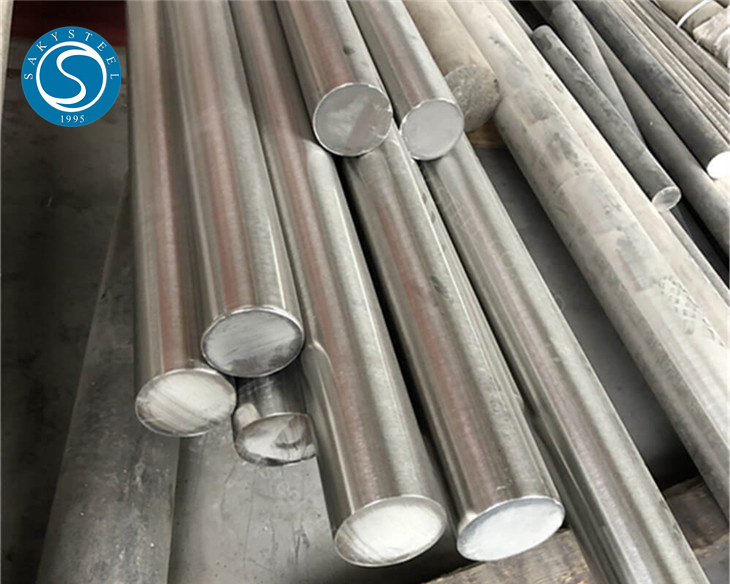

EN 1.4913 (X19CrMoNbVN11-1) Stainless Simbi Bar

Tsanangudzo Pfupi

SH

EN 1.4913 Stainless Simbi Bar:

SH Inoumbwa nechromium, molybdenum, niobium, uye vanadium, inopa yakanakisa oxidation kuramba, simba rekukambaira, uye kusimba kwenguva refu. Ichi chinyorwa chakanakira maindasitiri akadai sekugadzira magetsi, kugadzirwa kwemakemikari, uye aerospace, uko kusimba kwepamusoro, kusapisa kupisa, uye corrosion-resistant zvivakwa zvakakosha. Kugadzikana kwayo kwepamusoro kwekushisa kunoita kuti ive yakakwana kushandiswa muzvikamu zvakaita semaboilers, zvinopisa kupisa, uye maturbines, uko kushanda pasi pemamiriro akanyanya kwakakosha.

Zvinotsanangurwa zveX19CrMoNbVN11-1 simbi bar:

| Zvinotsanangurwa | EN 10269 |

| Giredhi | 1.4913 ,X19CrMoNbVN11-1 |

| Urefu | 1-12M & Inodiwa Hurefu |

| Surface Finish | Dema, Bright |

| Form | Round |

| End | Plain End, Beveled End |

| Mill Test Certificate | EN 10204 3.1 kana EN 10204 3.2 |

1.4913 Stainless simbi bhaa Chemical Kuumbwa:

| Giredhi | C | Mn | P | S | Cr | Ni | Mo | Al | V |

| 1.4913 | 0.17-0.23 | 0.4-0.9 | 0.025 | 0.015 | 10.0-11.5 | 0.20-0.60 | 0.5-0.8 | 0.02 | 0.1-0.3 |

EN 1.4913 simbi isina simbi bar inobatwa sei?

Maitiro ekupisa kupisa kweEN 1.4913 (X19CrMoNbVN11-1) Stainless simbi bhaa inosanganisira kugadzirisa annealing, kuderedza kushushikana, uye kuchembera. Solution annealing inowanzoitwa pakati pe1050 ° C uye 1100 ° C kuti homogenize chimiro uye kunyungudutsa carbides, ichiteverwa nekukurumidza kutonhora. Kubvisa kushushikana kunoitwa pa600°C kusvika 700°C kubvisa kushushikana kwasara kubva kumachining kana welding. Kuchembera kunoitwa pa700°C kusvika 750°C kuwedzera simba uye kuramba. Aya matanho ekupisa kupisa anonatsiridza iyo yakanyanya-tembiricha oxidation kuramba, simba remuchina, uye kukambaira kuramba, zvichiita kuti ive yakakodzera kudiwa kwepamusoro-tembiricha zvikumbiro.

Zvishandiso zve EN 1.4913 simbi isina simbi bar?

SH Zvimwe zvezvishandiso zvikuru zvinosanganisira:

1. Power Generation: Inoshandiswa mumagetsi emagetsi, kunyanya mumagetsi emhepo, boilers, uye kupisa kunopisa, uko kupikisa kutonhora kwakanyanya uye kuora kwakakosha.

2.Aerospace: Inoshandiswa mumagetsi e-turbine, zvikamu zvejini, uye zvimwe zvikamu zvepamusoro-tembiricha izvo zvinofanirwa kutsungirira kupisa kwakanyanya uye kumanikidzwa muindasitiri yemuchadenga.

3.Chemical Processing: Inoshandiswa mumakemikari emagetsi, kupisa kupisa, uye zvimwe midziyo inoratidzirwa kune nzvimbo dzinopisa uye kupisa kwakanyanya.

4.Petrochemical Indasitiri: Yakanakira zvikamu muzvirimwa zvepetrochemical, senge mareactor uye pombi masisitimu, anoshanda pasi pekupisa kwepamusoro uye kushushikana kwemagetsi.

5.Oil uye Gasi: Inoshandiswa mukuchera uye kuchenesa midziyo apo kusimba kwepamusoro-kupisa uye kupikisa oxidation uye corrosion zvakakosha pakushanda kwenguva refu.

6.Boiler Zvikamu:Inoshandiswa mukugadzira boiler machubhu, superheater machubhu, uye zvimwe zvikamu zvakakosha zvakaratidzwa kune yakakwirira-tembiricha nharaunda.

7.Heat Exchangers:Inoshandiswa mumachubhu ekupisa uye zvikamu nekuda kwekukwanisa kwayo kurwisa bhasikoro rinopisa uye kupisa kwepamusoro-soro.

1.4913 (X19CrMoNbVN11-1) Bhara Makiyi Hunhu

EN 1.4913 (X19CrMoNbVN11-1) ndeyepamusoro-inoita simbi isina tsvina alloy yakagadzirirwa kukwirisa-tembiricha uye yakanyanya-kunetsekana maapplication, kunyanya mukugadzira magetsi uye petrochemical maindasitiri. Heano maitiro akakosha echinyorwa ichi:

1. High-Temperature Resistance: Tembiricha Range: EN 1.4913 yakanyatsogadzirirwa kutsungirira tembiricha yakakwira, ichiita kuti ive yakanakira kushandiswa mumagetsi emagetsi, turbines, uye dzimwe nzvimbo dzinopisa zvakanyanya.

2. Yakanakisa Corrosion Resistance

Oxidation Resistance: Inopa kumira kwakanaka kune oxidation, ichiita kuti ive yakakodzera kushandiswa munzvimbo dzakaoma dzine tembiricha yakakwira uye midhiya ine hutsinye.

3. Simba Rakanaka uye Kuoma: Simba Repamusoro: EN 1.4913 inopa simba rakanaka pakupisa kwepamusoro uye inochengetedza maitiro ayo emagetsi kunyange pasi pekunetseka uye mitoro yakakwirira.

4. Alloy Composition: Key Elements: The alloy ine Chromium (Cr), Molybdenum (Mo), Niobium (Nb), uye Vanadium (V), iyo inowedzera simba rayo uye kuramba kune yakakwirira-yekushisa inokambaira. Izvi zvinoita kuti ive yakakodzera kuratidzwa kwenguva refu kune yakakwirira-tembiricha nharaunda.

5. Yakanaka Weldability uye Formability: Welding: EN 1.4913 inogona kusungirirwa uchishandisa nzira dzakajairwa dzakadai seTIG, MIG, uye coated electrode welding, kunyangwe preheating ingadikanwa kudzivirira kuumbwa kwe brittle phases.

6. Creep Resistance: Iyo alloy inoratidza yakanakisa creep resistance, zvichireva kuti inochengetedza simba rayo pamusoro penguva refu yekuratidzwa kune yakanyanya tembiricha uye kushushikana, izvo zvakakosha pakushandisa musimba nekugadzira magetsi.

7. Kuneta Kuramba: Iine zvakanaka kuneta kuramba, zvichireva kuti inogona kumira yakadzokororwa kurodha mitsetse, iyo yakakosha kune zvikamu zvinoenderana nekuchinja-chinja kwemamiriro ekushushikana.

Sei Sarudza isu?

•Iwe unogona kuwana iyo yakakwana zvinhu zvinoenderana nezvinodiwa zvako pamutengo unogoneka.

•Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekuendesa gonhi kumusuwo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

•Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pachitupa chebvunzo kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

•Isu tinovimbisa kupa mhinduro mukati me24hours (kazhinji muawa imwe chete)

•Ipa SGS, TUV, BV 3.2 chirevo.

•Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

•Ipa imwe-stop service.

Stainless Steel Bars Packing:

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,