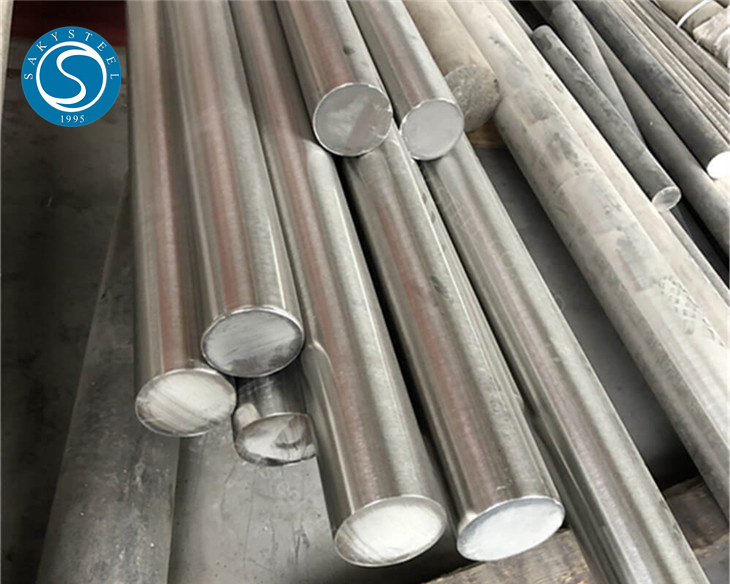

EN 1.4913 (X19CrMoNbVN11-1) Isixwexwe seSisimbi esingenaStainless Bar

Inkcazelo emfutshane:

I-EN 1.4913 (X19CrMoNbVN11-1) I-Stainless Steel Bar yi-alloy ephezulu yokusebenza eyenzelwe usetyenziso kwiindawo eziphezulu zokushisa.

EN 1.4913 Ibha yeNsimbi eNgatyiwayo:

I-EN 1.4913 (X19CrMoNbVN11-1) ibha yensimbi engenasici yi-alloy esebenza ngokuphezulu eyenzelwe usetyenziso kwiindawo ezinobushushu obuphezulu. Idityaniswe yichromium, molybdenum, niobium, kunye ne-vanadium, inika ukuxhathisa okugqwesileyo kwe-oxidation, amandla okurhubuluza, kunye nokuqina kwexesha elide. Esi sixhobo sifanelekile kumashishini afana nokuvelisa amandla, ukusetyenzwa kweekhemikhali, kunye ne-aerospace, apho amandla aphezulu, ukumelana nobushushu, kunye neepropati ezichasene nokuhlwa zibaluleke kakhulu. Uzinzo oluphezulu lwe-thermal luyenza igqibelele ukusetyenziswa kumacandelo afana neebhoyila, izitshintshi zobushushu, kunye nee turbines, apho ukusebenza phantsi kweemeko ezigqithisileyo kubalulekile.

Iimpawu ze-X19CrMoNbVN11-1 bar yentsimbi:

| Iinkcukacha | EN 10269 |

| IBanga | 1.4913 ,X19CrMoNbVN11-1 |

| Ubude | 1-12M & Ubude obufunekayo |

| Umphezulu Gqiba | Mnyama, Bright |

| Ifom | Umjikelo |

| Isiphelo | Isiphelo esicacileyo, iBeveled End |

| Mill Test Certificate | EN 10204 3.1 okanye EN 10204 3.2 |

I-1.4913 ibha yensimbi engenasici Ukubunjwa kwemichiza:

| IBanga | C | Mn | P | S | Cr | Ni | Mo | Al | V |

| 1.4913 | 0.17-0.23 | 0.4-0.9 | 0.025 | 0.015 | 10.0-11.5 | 0.20-0.60 | 0.5-0.8 | 0.02 | 0.1-0.3 |

I-EN 1.4913 ibha yensimbi engenasici iphathwa njani ubushushu?

Inkqubo yonyango lobushushu ye-EN 1.4913 (X19CrMoNbVN11-1) ibha yensimbi engenasici ibandakanya isisombululo se-annealing, ukunciphisa uxinzelelo, kunye nokuguga. Isisombululo se-annealing senziwa ngokuqhelekileyo phakathi kwe-1050 ° C kunye ne-1100 ° C ukuze i-homogenize isakhiwo kunye nokunyibilikisa i-carbides, ilandelwa kukupholisa ngokukhawuleza. Ukunciphisa uxinzelelo lwenziwa kwi-600 ° C ukuya kuma-700 ° C ukususa uxinzelelo olushiyekileyo kwi-machining okanye i-welding. Ukuguga kwenziwa ku-700°C ukuya kuma-750°C ukomeleza amandla kunye nokumelana nokurhubuluza. La manyathelo onyango lobushushu aphucula ukumelana ne-oxidation yezinto eziphezulu zobushushu, amandla oomatshini, kunye nokumelana nokunyuka, okwenza ukuba ifanelekele izicelo zobushushu obuphezulu.

Ukusetyenziswa kwe-EN 1.4913 ibha yensimbi engenasici?

I-EN 1.4913 (X19CrMoNbVN11-1) ibha yensimbi engenasici isetyenziswa ikakhulu kubushushu obuphezulu kunye noxinzelelo oluphezulu lwezicelo apho kufuneka amandla akhethekileyo, ukumelana ne-oxidation, kunye nokuqina kwexesha elide. Ezinye zezicelo eziphambili ziquka:

1.IsiZukulwana saMandla: Isetyenziswa kwizityalo zamandla, ngakumbi kwiiinjini zomphunga, iibhoyila, kunye nokutshintsha ubushushu, apho ukuxhathisa amaqondo obushushu aphezulu kunye nokudleka kubalulekile.

2.I-Aerospace: Baqeshwe kwiiblawudi ze-injini yomoya, amacandelo e-injini, kunye nezinye iindawo ezinobushushu obuphezulu ekufuneka zimelane nobushushu obugqithisileyo kunye noxinzelelo kwishishini le-aerospace.

I-3.I-Chemical Processing: Isetyenziswa kwii-reactors zekhemikhali, i-heater exchangers, kunye nezinye izixhobo ezivezwe kwiindawo ezinobungozi kunye nobushushu obuphezulu.

4.Ishishini lePetrokhemikhali: Lilungele amacandelo kwizityalo zepetrochemical, ezinje ngeactors kunye nenkqubo yemibhobho, esebenza phantsi koxinzelelo oluphezulu lobushushu kunye noomatshini.

I-5.I-oyile kunye neGesi: Ifakwe kwi-drilling kunye nezixhobo zokucoca apho amandla aphezulu okushisa kunye nokuchasana ne-oxidation kunye ne-corrosion kubalulekile ekusebenzeni kwexesha elide.

6.Amacandelo eBoiler:Isetyenziswa ekwenzeni iityhubhu zebhoyila, iityhubhu zeheater, kunye nezinye iindawo ezibalulekileyo ezivezwe kwindawo ezinobushushu obuphezulu.

I-7.I-Heat Exchangers: Iqeshwe kwiityhubhu zokutshintsha ubushushu kunye namacandelo ngenxa yokukwazi ukuxhathisa ibhayisikili ye-thermal kunye ne-high-temperature corrosion.

1.4913 (X19CrMoNbVN11-1) iBha yeempawu eziphambili

I-EN 1.4913 (X19CrMoNbVN11-1) yintsimbi yentsimbi esebenza ngokuphezulu eyenzelwe ubushushu obuphezulu kunye noxinzelelo oluphezulu, ngakumbi kwimveliso yamandla kunye nepetrochemical. Nazi iimpawu eziphambili zesi sixhobo:

1. Ukumelana nobushushu obuphezulu: Uluhlu lobushushu: I-EN 1.4913 yenzelwe ngokukodwa ukumelana namaqondo obushushu aphakamileyo, iyenza ilungele ukusetyenziswa kwizityalo zamandla, iiinjini zomphunga, kunye nezinye iindawo ezinobushushu obuphezulu.

2. Ukuchasa okugqwesileyo kwe-Corrosion

I-Oxidation Resistance: Inika ukuxhathisa okulungileyo kwi-oxidation, iyenza ilungele ukusetyenziswa kwindawo enzima kunye namaqondo obushushu aphezulu kunye neendaba ezinobundlobongela.

3. Amandla alungileyo kunye nokuqina: Amandla aphezulu: I-EN 1.4913 inika amandla amahle kumaqondo okushisa aphezulu kwaye igcina iimpawu zayo zomatshini naphantsi koxinzelelo kunye nemithwalo ephezulu.

4. Ukubunjwa kwe-alloy: Izinto eziphambili: I-alloy iqulethe i-Chromium (Cr), i-Molybdenum (Mo), i-Niobium (Nb), kunye ne-Vanadium (V), ephucula amandla ayo kunye nokuchasana nokunyuka kobushushu obuphezulu. Oku kuyenza ilungele ukuvezwa kwexesha elide kwiindawo ezinobushushu obuphezulu.

5. I-Weldability eLungileyo kunye noKuqulunqwa: I-Welding: EN 1.4913 inokudityaniswa kusetyenziswa iindlela eziqhelekileyo ezifana ne-TIG, i-MIG, kunye ne-coated electrode welding, nangona i-preheating ingafunwa ukuphepha ukubunjwa kwezigaba ezinqabileyo.

6. I-Creep Resistance: I-alloy ibonisa ukuxhathisa okugqwesileyo, oku kuthetha ukuba igcina amandla ayo kwixesha elide lokuvezwa kubushushu obuphezulu kunye noxinzelelo, okubalulekileyo kwizicelo zamandla kunye nokuveliswa kwamandla.

7. Ukumelana nokukhathala: Inokumelana nokudinwa okulungileyo, oku kuthetha ukuba inokumelana nemijikelo yokulayisha ephindaphindiweyo, ebalulekileyo kumacandelo aphantsi kweemeko zoxinzelelo eziguquguqukayo.

Kutheni Khetha thina?

•Unokufumana izinto ezigqibeleleyo ngokwemfuno yakho ngexabiso elincinci elinokwenzeka.

•Sikwabonelela ngeeReworks, FOB, CFR, CIF, kunye namaxabiso okuhambisa umnyango ukuya emnyango. Sicebisa ukuba wenze isivumelwano sokuthumela ngenqanawe okuya kuba nokonga kakhulu.

•Iimathiriyeli esizibonelelayo ziqinisekiswa ngokupheleleyo, ukusuka kwisiqinisekiso sovavanyo lwemathiriyeli ekrwada ukuya kwingxelo yokugqibela yomlinganiselo.(Iingxelo ziya kubonisa ngokwemfuneko)

•Siqinisekisa ukunika impendulo kwiiyure ezingama-24(ngokuqhelekileyo ngeyure enye)

•Ukubonelela nge-SGS, TUV, BV 3.2 ingxelo.

•Sizinikele ngokupheleleyo kubathengi bethu. Ukuba akunakwenzeka ukuhlangabezana neemfuno zakho emva kokuvavanya zonke iinketho, asiyi kukukhohlisa ngokwenza izithembiso zobuxoki eziza kudala ubudlelwane obuhle kubathengi.

•Ukubonelela ngenkonzo yokumisa enye.

UkuPakisha iiBha zeNtsimbi:

1. Ukupakisha kubaluleke kakhulu ngokukodwa kwimeko yokuthunyelwa kwamanye amazwe apho umthwalo udlula kwiitshaneli ezahlukeneyo ukuya kufika kwindawo yokugqibela, ngoko ke sibeka inkxalabo ekhethekileyo malunga nokupakishwa.

2. I-Saky Steel ipakisha iimpahla zethu ngeendlela ezininzi ezisekelwe kwiimveliso. Sipakisha iimveliso zethu ngeendlela ezininzi, ezinje,