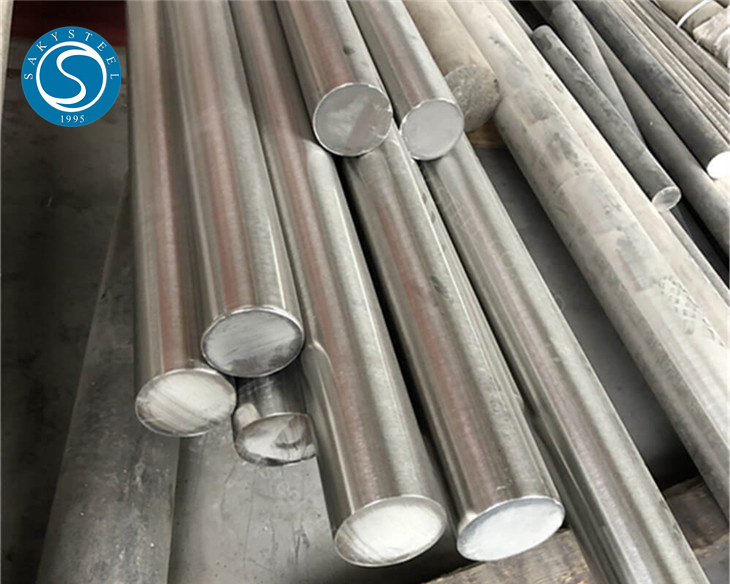

TS EN 1.4913 (X19CrMoNbVN11-1) Stainless Hlau Bar

Lus piav qhia luv luv:

TS EN 1.4913 (X19CrMoNbVN11-1) Stainless Steel Bar yog cov khoom siv ua haujlwm siab tsim los rau kev siv hauv qhov chaw kub kub.

EN 1.4913 Stainless hlau Bar:

TS EN 1.4913 (X19CrMoNbVN11-1) stainless hlau bar yog cov khoom siv ua haujlwm siab tsim los rau kev siv hauv qhov chaw kub kub. Ua los ntawm chromium, molybdenum, niobium, thiab vanadium, nws muaj oxidation zoo heev, creep zog, thiab lub sij hawm ntev. Cov khoom siv no zoo tagnrho rau kev lag luam xws li kev tsim hluav taws xob, kev ua tshuaj lom neeg, thiab aerospace, qhov chaw muaj zog, kub-resistant, thiab corrosion-resistant zog yog qhov tseem ceeb. Nws superior thermal stability ua rau nws zoo meej rau siv nyob rau hauv lub Cheebtsam xws li boilers, tshav kub exchangers, thiab turbines, qhov twg kev ua tau zoo nyob rau hauv huab mob yog qhov tseem ceeb.

Specifications ntawm X19CrMoNbVN11-1 steel bar:

| Specifications | TS EN 10269 |

| Qib | 1.4913 ,X19CrMoNbVN11-1 |

| Ntev | 1-12M & Ntev Ntev |

| Nto tiav | Dub, Dawb |

| Daim ntawv | Hloov |

| Xaus | Plain End, Beveled End |

| Mill Test Certificate | EN 10204 3.1 lossis EN 10204 3.2 |

1.4913 stainless hlau bar tshuaj muaj pes tsawg leeg:

| Qib | C | Mn | P | S | Cr | Ni | Mo | Al | V |

| 1.491 3 | 0.17-0.23 dr hab | 0.4-0.9 hli | 0.025 ib | 0.015 ib | 10.0-11.5 Nws | 0.20-0.60 Nws | 0.5-0.8 hli | 0.02 ib | 0.1-0.3 hli |

EN 1.4913 stainless hlau bar cua sov kho li cas?

Cov txheej txheem kho cua sov rau EN 1.4913 (X19CrMoNbVN11-1) stainless hlau bar suav nrog cov tshuaj annealing, kev ntxhov siab, thiab kev laus. Kev daws annealing feem ntau yog ua los ntawm 1050 ° C thiab 1100 ° C kom homogenize cov qauv thiab yaj cov carbides, ua raws li qhov txias txias. Kev ntxhov siab yog nqa tawm ntawm 600 ° C mus rau 700 ° C kom tshem tawm cov kev ntxhov siab uas nyob ntawm kev siv tshuab lossis vuam. Kev laus yog ua tiav ntawm 700 ° C mus rau 750 ° C txhawm rau txhim kho lub zog thiab nkag mus. Cov kauj ruam kev kho cua sov no txhim kho cov khoom siv kub-kub oxidation tsis kam, txhua yam muaj zog, thiab nkag siab tsis kam, ua rau nws tsim nyog rau kev thov kev siv kub kub.

Daim ntawv thov ntawm EN 1.4913 stainless hlau bar?

TS EN 1.4913 (X19CrMoNbVN11-1) stainless hlau bar feem ntau yog siv rau hauv high-temperature thiab high-stress daim ntawv thov qhov tshwj xeeb lub zog, oxidation kuj, thiab lub sij hawm ntev yuav tsum tau. Qee qhov kev siv tseem ceeb suav nrog:

1.Power Generation: Siv nyob rau hauv cov fais fab nroj tsuag, tshwj xeeb tshaj yog nyob rau hauv chav turbines, boilers, thiab tshav kub exchangers, qhov uas tsis kam mus rau high kub thiab corrosion yog ib qho tseem ceeb heev.

2.Aerospace: Ua hauj lwm nyob rau hauv turbine hniav, cav Cheebtsam, thiab lwm yam high-temperature qhov chaw uas yuav tsum tau tiv taus huab cua kub thiab siab nyob rau hauv lub aerospace kev lag luam.

3.Chemical Processing: Siv nyob rau hauv cov tshuaj reactors, tshav kub exchangers, thiab lwm yam khoom raug rau corrosive ib puag ncig thiab kub kub.

4.Petrochemical Kev Lag Luam: Zoo tagnrho rau cov khoom siv hauv cov nroj tsuag petrochemical, xws li cov reactors thiab cov kav dej, uas ua haujlwm nyob rau hauv siab thermal thiab mechanical stress.

5.Oil thiab Gas: Siv nyob rau hauv drilling thiab refining cov cuab yeej uas kub-siab zog thiab tsis kam mus oxidation thiab corrosion yog qhov tseem ceeb rau kev ua tau zoo mus ntev.

6.Boiler Cheebtsam: Siv nyob rau hauv kev tsim cov boiler raj, superheater raj, thiab lwm yam tseem ceeb qhov chaw raug rau high-temperature chav chaw.

7.Heat Exchangers: Ua hauj lwm nyob rau hauv lub tshav kub exchanger raj thiab cov khoom vim nws muaj peev xwm tiv thaiv thermal cycling thiab high-temperature corrosion.

1.4913 (X19CrMoNbVN11-1) Bar Cov yam ntxwv tseem ceeb

TS EN 1.4913 (X19CrMoNbVN11-1) yog ib qho kev ua tau zoo ntawm cov hlau tsis muaj steel hlau tsim los rau cov kev siv kub thiab kev ntxhov siab, tshwj xeeb tshaj yog nyob rau hauv kev tsim hluav taws xob thiab kev lag luam petrochemical. Nov yog cov yam ntxwv tseem ceeb ntawm cov khoom no:

1. High-Temperature Resistance: Temperature Range: EN 1.4913 tshwj xeeb yog tsim los tiv thaiv qhov kub siab, ua rau nws zoo tagnrho rau siv hauv cov chaw tsim hluav taws xob, chav turbines, thiab lwm qhov chaw kub kub.

2. Zoo heev Corrosion Resistance

Oxidation Resistance: Nws muaj kev tiv thaiv zoo rau oxidation, ua rau nws haum rau siv nyob rau hauv hnyav ib puag ncig nrog kub thiab aggressive media.

3. Lub zog zoo thiab tawv tawv: Lub zog siab: EN 1.4913 muab lub zog zoo ntawm qhov kub thiab txias thiab tswj nws cov khoom siv kho tshuab txawm tias muaj kev ntxhov siab thiab kev thauj khoom siab.

4. Alloy Composition: Cov ntsiab lus tseem ceeb: Cov hlau muaj Chromium (Cr), Molybdenum (Mo), Niobium (Nb), thiab Vanadium (V), uas txhim kho nws lub zog thiab tiv thaiv kev kub ntxhov. Qhov no ua rau nws tsim nyog rau lub sij hawm ntev raug rau qhov kub thiab txias ib puag ncig.

5. Zoo Weldability thiab Formability: Vuam: EN 1.4913 tuaj yeem welded siv ntau txoj hauv kev xws li TIG, MIG, thiab coated electrode vuam, txawm hais tias yuav tsum tau preheating kom tsis txhob muaj cov theem nkig.

6. Creep Resistance: Cov alloy nthuav tawm zoo heev creep tsis kam, txhais tau tias nws tuav nws lub zog nyob rau lub sij hawm ntev ntawm kev raug kub thiab kev ntxhov siab, uas yog ib qho tseem ceeb rau kev siv nyob rau hauv lub zog thiab lub zog tsim.

7. Fatigue Resistance: Nws muaj kev qaug zog zoo, txhais tau hais tias nws tuaj yeem tiv taus kev rov ua haujlwm rov qab, uas yog qhov tseem ceeb rau cov khoom uas cuam tshuam rau cov kev ntxhov siab hloov pauv.

Vim li cas thiaj xaiv peb?

•Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

•Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

•Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

•Peb lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

•Muab SGS, TUV, BV 3.2 qhia.

•Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

•Muab kev pabcuam ib-nres.

Stainless hlau Bars Packing:

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,