1.4923 X22CrMoV12-1 Litšepe Tse Ncha

Tlhaloso e Khutšoanyane:

Fumana litšepe tse chitja tsa 1.4923 X22CrMoV12-1 tse loketseng lisebelisoa tsa mocheso o phahameng joalo ka li-turbine le liboiler. Lekola thepa, boholo, le likhetho tsa ho iketsetsa.

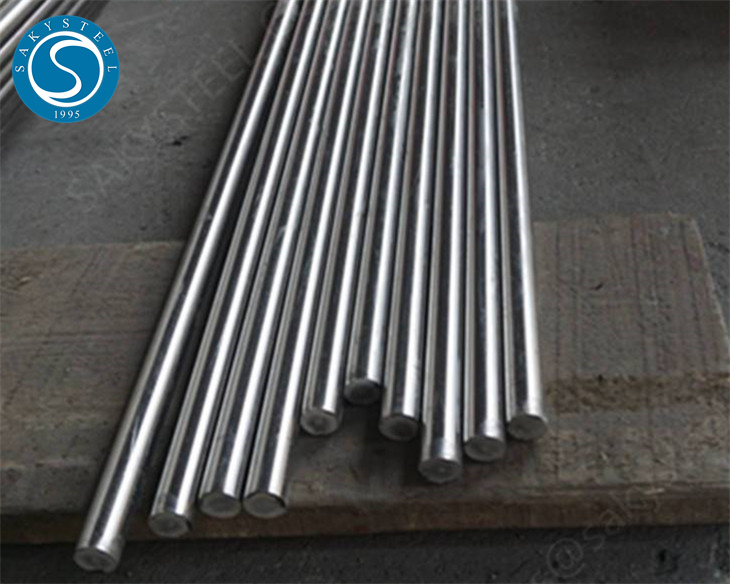

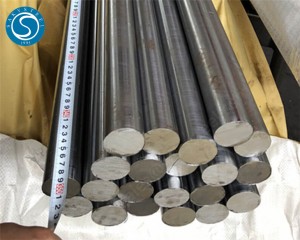

1.4923 X22CrMoV12-1 Round Bars:

1.4923 (X22CrMoV12-1) litšepe tse chitja ke litšepe tse nang le matla a phahameng, tse sa keneleng mocheso tse etselitsoeng lits'ebetso maemong a feteletseng. Ka khanyetso e ntle ea mocheso o phahameng le oxidation, hangata li sebelisoa ka mahare a turbine, likarolo tsa boiler, le liphaephe tse phahameng tsa khatello. Sesebediswa sena se fana ka sebopeho se leka-lekaneng sa chromium, molybdenum, le vanadium, se netefatsang lisebelisoa tse phahameng tsa mochini, ho kenyeletsoa matla a phahameng a tsitsipano, ho tiea, le ho tšoarella, leha mocheso o phahame ho fihla ho 600 ° C. E loketse liindasteri tse hlokang ho tšepahala tlas'a khatello ea mocheso, mekoallo ea 1.4923 e pota-potileng e kopana le litekanyetso tse thata tsa DIN le EN, ho netefatsa boleng bo tsitsitseng le ts'ebetso.

Litlhaloso tsa X22CrMoV12-1 Round Bar:

| Ultrasonic Test Standard | DIN EN 10269 |

| Kereiti | 1.4923, X22CrMoV12-1 |

| Bolelele | 1-12M & Bolelele bo Hlokehang |

| Surface Finish | E ntšo, e Khanyang |

| Sebopeho | Ratoa |

| QETA | Qetello e Ntle, Qetello e Beveled |

| Setifikeiti sa Tlhahlobo ea Mill | EN 10204 3.1 kapa EN 10204 3.2 |

1.4923 Round Bar Equivalent Grades:

| DIN | WERKSTOFF NR. | AISI |

| X22CrMoV12-1 | 1.4923 | X22 |

Sebopeho sa X22CrMoV12-1 Round Bar Chemical:

| C | Mn | P | S | Si | Cr | Ni | Mo |

| 0.18-0.24 | 0.4-0.9 | 0.025 | 0.015 | 0.50 | 11.0-12.5 | 0.3-0.8 | 0.8-1.2 |

1.4923 Litšepe tsa Mechanical Thepa:

| Lintho tse bonahalang | Yield Strength (Mpa) | Tensile Strength (Mpa) | Ho thatafala |

| 1.4923 | 600 | 750-950 | 240-310 HBW |

Likarolo tsa 1.4923 Steel (X22CrMoV12-1):

1.Ho hanyetsa mocheso o motle haholo:1.4923 tšepe e boloka thepa e tsitsitseng ea mechine tlas'a mocheso o phahameng (ho fihlela ho 600 ° C), e leng se etsang hore e be se loketseng bakeng sa tšebeliso ea nako e telele libakeng tse phahameng tsa mocheso le tse phahameng.

2.Matla a Phahameng le ho Tiea:Ka matla a phahameng a ho tsitsa (750-950 MPa) le boima bo ikhethang, tšepe ena e tiisa ts'ebetso e ka tšeptjoang tlas'a khatello ea mocheso le mochine.

3.Oxidation le Corrosion Resistance:Sebopeho sa alloy ea eona, e nang le chromium e phahameng (10.5-12.5%) le molybdenum (0.9-1.2%), e fana ka khanyetso e babatsehang ho oxidation le corrosion maemong a phahameng a mocheso.

4.Tshebo e Ntle ea Mocheso:Tšepe ea 1.4923 e ka ntlafatsoa ka ho tima le ho halefa, ho matlafatsa ho thatafala ha eona, matla le ho tiea ho fihlela litlhoko tse fapaneng tsa boenjiniere.

5.Wide Industrial Applications:Hangata e sebelisoa likarolong tse pepesehileng mocheso le likhatello tse phahameng, tse kang:Mahare a turbine ea mouoane,Likaroloana tsa boiler, Li-heaters tsa mocheso, liphaephe tse phahameng tsa khatello,Ho lumellana le Melao ea Machaba.

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

1.4923 Round Bar Packing:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,