17-4PH 630 Stainless Steel Bar

Tlhaloso e Khutšoanyane:

SAKYSTEEL e fana ka litšepe tse 17-4PH (630) tse nang le matla a matla le ho hanyetsa kutu bakeng sa ts'ebeliso ea sepakapaka, leoatleng le indastering.

Saky Steel's 17-4PH / 630 / 1.4542 ke e 'ngoe ea litšepe tsa alloy tse sebelisoang ka ho fetesisa tsa chromium-nickel tse nang le kenyelletso ea koporo, pula e thata e thata ka sebopeho sa martensitic. E khetholloa ka khanyetso e phahameng ea kutu ha e ntse e boloka thepa ea matla a phahameng, ho kenyeletsa le boima. Tšepe e ka sebetsa maemong a mocheso ho tloha ho -29 ℃ ho isa ho 343 ℃, ha e ntse e boloka liparamente tse batlang li le ntle. Ho phaella moo, lisebelisoa tsa sehlopha sena li khetholloa ke ductility e batlang e le ntle 'me ho hanyetsa ha bona ha kutu ho bapisoa le 1.4301 / X5CrNi18-10.

17-4PH, eo hape e tsejoang e le UNS S17400, ke tšepe e sa hloekang e thatafatsang pula ea martensitic. Ke thepa e feto-fetohang le e sebelisoang haholo liindastering tse fapaneng, joalo ka sefofane, nyutlelie, petrochemical, le phepelo ea lijo.

17-4PH e na le matla a phahameng, khanyetso e ntle ea kutu, le boima bo botle ha bo bapisoa le litšepe tse ling tse se nang tšepe. Ke motsoako oa 17% chromium, 4% nickel, 4% koporo, le palo e nyane ea molybdenum le niobium. Ho kopana ha lintho tsena ho fa tšepe thepa ea eona e ikhethang.

Ka kakaretso, 17-4PH ke sesebelisoa se feto-fetohang le se sebetsang se fanang ka tekatekano e ntle ea thepa bakeng sa lits'ebetso tse fapaneng.

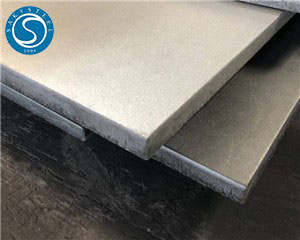

| Stainless Steel Round Bar Bright Products Show: |

| Setšoantšo sa 630tšepe e sa hloekang: |

Litlhaloso :ASTM A564 /ASME SA564

Kereiti:AISI 630 SUS630 17-4PH 1.4542 PH

Bolelele :5.8M,6M & Bolelele bo Hlokehang

Round Bar Diameter :4.00 limilimithara ho 400 limilimithara

Bare e Khanyang :4-100 limilimithara,

Mamello :H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 kapa ho latela litlhoko tsa bareki

Boemo :Cold Drawn & polished Cold Drawn, E peeled & Forged

Surface Finish :E Ntšo, E Khanyang, E bentšitsoeng, E Makhulo E Fetohileng, NO.4 Qetella, Matt Qetella

Foromo :Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged jj.

QETA :Qetello e Ntle, Qetello e Beveled

| Sebopeho sa Lik'hemik'hale sa Stainless Steel Bar Grades: |

| Lebitso la UNS | Mofuta | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Lintlha Tse Ling |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 | 630 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 15.00–17.50 | 3.00–5.00 | - | - | - | 3.00–5.00 | C |

| S17700 | 631 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–18.00 | 6.50–7.75 | - | - | - | - | - |

| S15700 | 632 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–16.00 | 6.50–7.75 | - | 2.00–3.00 | - | - | - |

| S35500 | 634 | 0.10–0.15 | 0.50–1,25 | 0.040 | 0.030 | 0.50 | 15.00–16.00 | 4.00–5.00 | - | 2.50–3,25 | - | - | D |

| S17600 | 635 | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–17.50 | 6.00–7.50 | 0.40 | - | - | - | - |

| S15500 | XM-12 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–15.50 | 3.50–5,50 | - | - | - | 2.50–4,50 | C |

| S13800 | XM-13 | 0.05 | 0.20 | 0.040 | 0.008 | 1.00 | 12.25–13.25 | 7.50–8.50 | 0.90–1.35 | 2.00–2.50 | - | - | E |

| S45500 | XM-16 | 0.03 | 0.50 | 0.015 | 0.015 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 0.90–1.40 | 1.50–2,50 | F |

| S45503 | - | 0.010 | 0.50 | 0.010 | 0.010 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 1.00–1.35 | 1.50–2,50 | F |

| S45000 | XM-25 | 0.05 | 1.00 | 0.030 | 0.030 | 0.50 | 14.00–16.00 | 5.00–7.00 | - | - | - | 1.25–1,75 | G |

| S46500 | - | 0.02 | 0.25 | 0.040 | 0.030 | 1.00 | 11.00–13.0 | 10.75–11.25 | 0.15–0,50 | 0.75–1,25 | - | - | E |

| S46910 | - | 0.030 | 1.00 | 0.040 | 0.020 | 1.00 | 11.00–12.50 | 8.00–10.00 | 0.50–1.20 | 3.0–5.0 | - | 1.5–3,5 | - |

| S10120 | - | 0.02 | 1.00 | 0.040 | 0.015 | 0.25 | 11.00–12.50 | 9.00–11.00 | 1.10 | 1.75–2.25 | 0.20–0.50 | - | E |

| S11100 | - | 0.02 | 0.25 | 0.040 | 0.010 | 0.25 | 11.00–12.50 | 10.25–11.25 | 1.35–1,75 | 1.75–2.25 | 0.20–0.50 | - | E |

| 17-4PH Mephato e Tšoanang ea Stainless Steel Bar: |

| TS'ELISO | UNS | WERKSTOFF NR. | HLOMPHO | JIS | EN | BS | GOST |

| 17-4PH | S17400 | 1.4542 |

| 17-4PH Phekolo ea Tharollo ea Stainless Bar: |

| Kereiti | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Matla a Kotulo 0.2% Bopaki (MPa) min | Ho thatafala | |

| Rockwell C max | Brinell (HB) max | ||||

| 630 | - | - | - | 38 | 363 |

Ntlha ea bohlokoa: Boemo ba A 1900±25°F[1040±15°C](ho bata ho ea ka tlase ho 90°F(30°C))

1.4542 Litlhokahalo tsa Teko ea Mechini Ka mor'a Kalafo ea Mocheso e Thatafatsang Lilemo:

Matla a tšepe :Yuniti – ksi (MPa) , Bonyane

Yeild Strength :0.2 % Offset , Unit – ksi (MPa) , Minimum

Elongation :ka 2″, Yuniti : % , Bonyane

Ho thatafala :Rockwell, Maximum

17-4PH Thepa ea Mochini oa tšepe e sa hloekang ka Boemo ba Phekolo ea Mocheso:

| H900 | H925 | H 1025 | H 1075 | H 1100 | H 1150 | H 1150-M | |

| Ultimate Tensile Matla, ksi | 190 | 170 | 155 | 145 | 140 | 135 | 115 |

| 0.2% Matla a Puno, ksi | 170 | 155 | 145 | 125 | 115 | 105 | 75 |

| Elongation % ho 2″ kapa 4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Phokotso ea Sebaka,% | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Hardness, Brinell (Rockwell) | 388 (C 40) | 375 (C 38) | 331 (C 35) | 311 (C 32) | 302 (C 31) | 277 (C 28) | 255 (C 24) |

| Tšusumetso ea Charpy V-Notch, ft - lbs | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Khetho ea ho qhibilihisa: |

1 EAF: Sebōpi sa Motlakase sa Arc

2 EAF+LF+VD: Ho qhibilihisoa ho hloekisitsoeng le ho ntša metsi ka vacuum

3 EAF + ESR: Electro Slag Remelting

4 EAF + PESR: sepakapaka se sireletsang Electro Slag Remelting

5 VIM + PESR: Ho qhibiliha ha vacuum induction

| Khetho ea ho Phekola Mocheso: |

1 +A: E hlophisitsoe (e tletse / e bonolo / spheroidizing)

2 +N: E tloaelehileng

3 +NT: E tloaelehile ebile e halefile

4 + QT: E tingoe ebile e halefile (metsi / oli)

5 +AT: Tharollo e hanetsoe

6 +P: Pula e thatafetse

| Kalafo ea Mocheso: |

Phekolo ea Tharollo (Boemo ba A) - Litšepe tse sa hloekang tsa Kereiti ea 630 li futhumatsoa ka 1040 ° C bakeng sa 0.5 h, ebe li pholile moea ho isa ho 30 ° C. Likarolo tse nyane tsa limaraka tsena li ka tima oli.

Ho thatafala - Litšepe tse sa hloekang tsa Kereiti ea 630 li thatafatsoa ke lilemo ka mocheso o tlase ho fihlela thepa e hlokahalang ea mochini. Nakong ea ts'ebetso, ho fetoha ha mebala ka holimo ho etsahala ho lateloa ke ho fokotseha ho 0.10% bakeng sa boemo ba H1150, le 0.05% bakeng sa boemo ba H900.

| Maemo a 17-4PH Stainless Steel |

17-4PH tšepe e sa hloekang e lumellana le mefuta e mengata ea litekanyetso le litlhaloso tsa machaba, ho netefatsa boleng bo tšepahalang le ts'ebetso ho pholletsa le liindasteri tse kang sefofane, matla le ts'ebetso ea lik'hemik'hale.

| Mokhatlo o Tloaelehileng | Tlhaloso | Tlhaloso |

|---|---|---|

| ASTM | ASTM A564 / A564M | Tloaelo bakeng sa mekoallo ea tšepe e sa hloekang e thata-thata le e feliloeng ke serame |

| ASTM A693 | Specification bakeng sa pula-hardening stainless steel plate, sheet, and strip | |

| ASTM A705 / A705M | Litlhaloso bakeng sa litšepe tse thata-tse thata-thata le tšepe e thibelang mocheso | |

| ASME | ASME SA564 / SA693 / SA705 | Litlhaloso tsa khoutu ea sekepe sa khatello e lekanang |

| AMS (Sefofane) | AMS 5643 | Aerospace spec bakeng sa bar, terata, forgings, le mehele ho 17-4PH e nang le tharollo le botsofali. |

| AMS 5622 | Letlapa, letlapa le hlobolisa | |

| EN / DIN | EN 1.4542 / DIN X5CrNiCuNb16-4 | Lebitso la Europe bakeng sa 17-4PH e nang le sebopeho le thepa e tšoanang |

| UNS | UNS S17400 | Lebitso la Sisteme e Kopanetsoeng ea ho Nomola |

| ISO | ISO 15156-3 | Ho tšoaneleha bakeng sa ho sebelisoa lisebelisoa tsa sebaka sa oli libakeng tsa khase e bolila |

| NACE | MR0175 | Lintho tse hlokahalang bakeng sa ho hanyetsa khatello ea kelello ea sulfide |

| Ke Hobane'ng ha U Re Khetha: |

1. U ka fumana boitsebiso bo phethahetseng ho ea ka tlhokahalo ea hau bonyane theko e ka khonehang.

2. Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

3. Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela.(Litlaleho li tla hlaha ho latela tlhoko)

4. e tiisetso ea ho fana ka karabo nakong ea lihora tse 24(hangata ka hora e tšoanang)

5. U ka fumana mefuta e meng ea li-stock, ho tsamaisoa ha leloala ka ho fokotsa nako ea tlhahiso.

6. Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

| Netefatso ea Boleng ea SAKY STEEL (ho kenyeletsoa tse senyang le tse sa senyeheng) |

1. Teko ea Visual Dimension

2. Tlhahlobo ea mochine joalo ka tensile, Elongation le phokotso ea sebaka.

3. Tlhahlobo ea Ultrasonic

4. Tlhahlobo ea tlhahlobo ea lik'hemik'hale

5. Teko ea boima

6. Teko ea tšireletso ea likoti

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Tlhahlobo ea tšusumetso

10. Metallography Teko ea Teko

| Sephutheloana |

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,

17-4PH, 630 le X5CrNiCuNb16-4 / 1.4542 e fanoa ka mokhoa oa mekoallo e chitja, lishiti, mekoallo e bataletseng le hlobo e batang. Thepa e sebelisoa haholo indastering ea sefofane, ea metsing, ea pampiri, ea matla, ea maoatle le ea lijo bakeng sa likarolo tsa mochini o boima, lihlahla, li-blades tsa turbine, li-couplings, screws, shafts drive, linate, lisebelisoa tsa ho lekanya.

1. Indasteri ea Sepakapaka

-

Likarolo tsa enjene ea turbine (li-impellers, shafts, housings)

-

Likarolo tsa lisebelisoa tsa ho lulisa

-

Li-fasteners (liboutu, linate) le lihokelo tsa sebopeho

-

Likarolo tsa tsamaiso ea Hydraulic

2. Indasteri ea Oli le Khase

-

Lisebelisoa tsa Downhole (lithupa tsa ho cheka, litulo tsa valve, lisebelisoa tsa lipeipi)

-

Likarolo tsa li-valve tse thibelang ho bola

-

Lisebelisoa tsa lisebelisoa tsa oli (li-shafts tsa pompo, matlo, mehele ea ho tiisa)

3. Indasteri ea Ts'ebetso ea Lik'hemik'hale

-

Lipompo le li-valve tse sebelisoang libakeng tse nang le asiti

-

Lisebelisoa tsa mocheso le lijana tsa khatello

-

Li-reactors le li-agitator shafts

-

Lisebelisoa bakeng sa litanka tsa polokelo

4. Phetoho ea Lijo & Thepa ea Bongaka

-

Mefuta ea lijo-thollo le likarolo tsa koloi

-

Likarolo tsa li-sterilizers tsa khatello e phahameng

-

Lisebelisoa tsa ho buoa le lisebelisoa tsa bongaka (ho hlokahala setifikeiti)

-

Likarolo tsa mekhoa ea ho laola khatello ea meriana

5. Boenjiniere ba Marine le Offshore

-

Li-propeller shafts le likopano tsa propulsion

-

Li-shafts tsa pompo ea metsi a leoatle le likarolo tsa ho tiisa

-

Li-fasteners le lihokelo tsa sebopeho ka har'a likepe tsa likepe

-

Likarolo tse thibelang ho bola bakeng sa liforomo tsa maoatle

6. Phaliso ea Nyutlelie le Matla

-

Lifastening tsa meaho ea li-reactor tsa nyutlelie

-

Li-tube bundle li tšehetsa li-heaters tsa mocheso

-

Li-valve tsa hydraulic le 'mele ea pompo

-

Likarolo tsa li-valve tsa mocheso o phahameng

7. Indasteri ea Mold le Lisebelisoa

-

Liforeimi tsa hlobo tsa ente

-

Matla a phahameng a etsang li-shafts le litšehetso

-

Tataisa li-post le lihlahla bakeng sa li-stamping hlobo

8. Mechini e Akaretsang & Boiketsetso

-

Likarolo tsa phetisetso joalo ka li-gear shafts, couplings le li-spindle

-

Litšepe tsa mechine le lithupa tsa ho beha maemo ka har'a li-automation system

-

Melamu ea piston ea hydraulic ea indasteri