17-4PH 630 Bwalo lachitsulo chosapanga dzimbiri

Kufotokozera Kwachidule:

SAKYSTEEL imapereka 17-4PH (630) zitsulo zosapanga dzimbiri zokhala ndi mphamvu zambiri komanso kukana dzimbiri pazamlengalenga, zam'madzi, komanso kugwiritsa ntchito mafakitale.

Saky Steel's 17-4PH / 630 / 1.4542 ndi imodzi mwazitsulo zodziwika bwino komanso zogwiritsidwa ntchito kwambiri zosapanga dzimbiri za chromium-nickel alloy zokhala ndi zowonjezera zamkuwa, mvula yowumitsidwa ndi kapangidwe ka martensitic. Amadziwika ndi kukana kwambiri kwa dzimbiri pomwe amakhalabe ndi mphamvu zambiri, kuphatikiza kuuma. Zitsulo zimatha kugwira ntchito pa kutentha kuchokera -29 ℃ mpaka 343 ℃, ndikusunga magawo abwino. Kuphatikiza apo, zida zomwe zili mugiredi iyi zimadziwika ndi ductility wabwino ndipo kukana kwawo kwa dzimbiri kumafanana ndi 1.4301 / X5CrNi18-10.

17-4PH, yomwe imadziwikanso kuti UNS S17400, ndi chitsulo chosapanga dzimbiri cholimba cha martensitic. Ndizinthu zosunthika komanso zogwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana, monga zakuthambo, nyukiliya, petrochemical, ndi kukonza chakudya.

17-4PH ili ndi mphamvu zambiri, kukana bwino kwa dzimbiri, komanso kuuma bwino poyerekeza ndi zitsulo zina zosapanga dzimbiri. Ndi osakaniza 17% chromium, 4% faifi tambala, 4% mkuwa, ndi pang'ono molybdenum ndi niobium. Kuphatikizana kwa zinthuzi kumapereka zitsulo zamtengo wapatali.

Ponseponse, 17-4PH ndichinthu chosunthika komanso chothandiza chomwe chimapereka kuchuluka kwazinthu zamagwiritsidwe osiyanasiyana.

| Stainless Steel Round Bar Bright Products Show: |

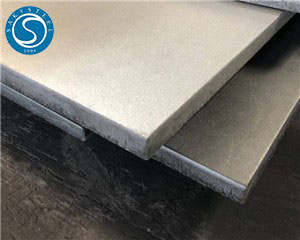

| Zithunzi za 630zitsulo zosapanga dzimbiri: |

Zofotokozera:ASTM A564/ASME SA564

Gulu:AISI 630 SUS630 17-4PH 1.4542 PH

Utali:5.8M, 6M & Utali Wofunika

Round Bar Diameter:4.00mm kuti 400mm

Bright Bar :4mm-100mm,

Kulekerera :H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 kapena malinga ndi zomwe kasitomala amafuna

Mkhalidwe :Zokoka Zozizira & Zopukutidwa Zozizira, Zosendedwa & Zopangidwa

Surface Finish :Wakuda, Wowala, Wopukutidwa, Wokhotakhota, NO.4 Malizani, Matt Finish

Fomu :Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged Etc.

TSIRIZA :Plain End, Beveled End

| Makasitomala Opangidwa ndi Chemical: |

| Kusankhidwa kwa UNS | Mtundu | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Zinthu Zina |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 | 630 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 15.00–17.50 | 3.00–5.00 | - | - | - | 3.00–5.00 | C |

| S17700 | 631 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–18.00 | 6.50–7.75 | - | - | - | - | - |

| S15700 | 632 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–16.00 | 6.50–7.75 | - | 2.00–3.00 | - | - | - |

| S35500 | 634 | 0.10–0.15 | 0.50–1.25 | 0.040 | 0.030 | 0.50 | 15.00-16.00 | 4.00–5.00 | - | 2.50–3.25 | - | - | D |

| S17600 | 635 | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–17.50 | 6.00–7.50 | 0.40 | - | - | - | - |

| S15500 | XM-12 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–15.50 | 3.50–5.50 | - | - | - | 2.50–4.50 | C |

| S13800 | XM-13 | 0.05 | 0.20 | 0.040 | 0.008 | 1.00 | 12.25–13.25 | 7.50–8.50 | 0.90–1.35 | 2.00–2.50 | - | - | E |

| S45500 | XM-16 | 0.03 | 0.50 | 0.015 | 0.015 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 0.90–1.40 | 1.50–2.50 | F |

| S45503 | - | 0.010 | 0.50 | 0.010 | 0.010 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 1.00–1.35 | 1.50–2.50 | F |

| S45000 | XM-25 | 0.05 | 1.00 | 0.030 | 0.030 | 0.50 | 14.00–16.00 | 5.00–7.00 | - | - | - | 1.25–1.75 | G |

| S46500 | - | 0.02 | 0.25 | 0.040 | 0.030 | 1.00 | 11.00–13.0 | 10.75–11.25 | 0.15–0.50 | 0.75–1.25 | - | - | E |

| S46910 | - | 0.030 | 1.00 | 0.040 | 0.020 | 1.00 | 11.00–12.50 | 8.00–10.00 | 0.50–1.20 | 3.0–5.0 | - | 1.5–3.5 | - |

| S10120 | - | 0.02 | 1.00 | 0.040 | 0.015 | 0.25 | 11.00–12.50 | 9.00–11.00 | 1.10 | 1.75–2.25 | 0.20–0.50 | - | E |

| S11100 | - | 0.02 | 0.25 | 0.040 | 0.010 | 0.25 | 11.00–12.50 | 10.25–11.25 | 1.35–1.75 | 1.75–2.25 | 0.20–0.50 | - | E |

| 17-4PH Magiredi Ofanana Azitsulo Zachitsulo Zosapanga dzimbiri: |

| ZOYENERA | UNS | Mbiri ya WERKSTOFF NR. | AFNOR | JIS | EN | BS | Mtengo wa GOST |

| 17-4 PH | S17400 | 1.4542 |

| 17-4PH Stainless Bar Solution Chithandizo: |

| Gulu | Mphamvu ya Tensile (MPa) min | Elongation (% mu 50mm) min | Zokolola Zamphamvu 0.2% Umboni (MPa) min | Kuuma | |

| Rockwell C max | Brinell (HB) max | ||||

| 630 | - | - | - | 38 | 363 |

Zindikirani: Chikhalidwe A 1900±25°F[1040±15°C](kuzizira ngati n'kofunikira kuchepera 90°F(30°C))

1.4542 Zofunikira Zoyezetsa Pamakina Pambuyo Kulimbitsa Ukalamba Chithandizo:

Kulimba kwamakokedwe :Unit – ksi (MPa) , Minimum

Yeild Strength:0.2 % Offset , Unit – ksi (MPa) , Minimum

Elongation:mu 2 ″, Unit : % , Minimum

Kuuma :Rockwell, Maximum

17-4PH Katundu Wamakina Opanda Zitsulo Zopanda Pake ndi Chikhalidwe Chochizira Kutentha:

| pa H900 | ndi h925 | Mtengo wa H1025 | Mtengo wa h1075 | Mtengo wa H1100 | Mtengo wa H1150 | H 1150-M | |

| Ultimate Tensile Mphamvu, ksi | 190 | 170 | 155 | 145 | 140 | 135 | 115 |

| 0.2% Mphamvu Zokolola, ksi | 170 | 155 | 145 | 125 | 115 | 105 | 75 |

| Elongation % mu 2 ″ kapena 4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Kuchepetsa Malo,% | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Kuuma, Brinell (Rockwell) | 388 (C 40) | 375 (C 38) | 331 (C 35) | 311 (C 32) | 302 (C 31) | 277 (C 28) | 255 (C 24) |

| Impact Charpy V-Notch, ft - lbs | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Njira Yosungunulira: |

1 EAF: Ng'anjo ya Electric Arc

2 EAF+LF+VD: Kusungunula-kusungunula komanso kutsuka mpweya

3 EAF + ESR: Electro Slag Remelting

4 EAF + PESR: chilengedwe choteteza Electro Slag Remelting

5 VIM + PESR: Kusungunuka kwa vacuum induction

| Njira Yochizira Kutentha: |

1 +A: Yowonjezera (yodzaza / yofewa / spheroidizing)

2 +N: Zokhazikika

3 +NT: Wokhazikika komanso wofatsa

4 + QT: Kuzimitsidwa ndi kutentha (madzi / mafuta)

5 + AT: Yankho latsekedwa

6 +P: Mvula yavuta

| Chithandizo cha kutentha: |

Chithandizo cha njira (Chikhalidwe A) - Zitsulo zosapanga dzimbiri za Gulu 630 zimatenthedwa pa 1040 ° C kwa 0.5 h, kenako zimaziziritsidwa mpaka 30 ° C. Zigawo zing'onozing'ono zamagulu awa zimatha kuzimitsidwa ndi mafuta.

Kuumitsa - Zitsulo zosapanga dzimbiri za Grade 630 zimaumitsidwa ndi zaka pa kutentha kochepa kuti zikwaniritse zofunikira zamakina. Panthawiyi, kusinthika kwapamwamba kumachitika ndikutsatiridwa ndi kuchepa kwa 0.10% kwa chikhalidwe H1150, ndi 0.05% pa chikhalidwe H900.

| Miyezo ya 17-4PH Stainless Steel |

17-4PH zitsulo zosapanga dzimbiri zimagwirizana ndi mitundu yosiyanasiyana ya mayiko ndi machitidwe, kuonetsetsa kuti ntchito yodalirika ndi yodalirika m'mafakitale monga mlengalenga, mphamvu, ndi kukonza mankhwala.

| Standard Organisation | Kufotokozera | Kufotokozera |

|---|---|---|

| Chithunzi cha ASTM | ASTM A564/A564M | Muyezo wa mipiringidzo yazitsulo zosapanga dzimbiri zotentha komanso zomaliza zoziziritsa zaka |

| ASTM A693 | Mafotokozedwe a mvula-youmitsa zitsulo zosapanga dzimbiri, pepala, ndi mizere | |

| ASTM A705/A705M | Mtsinje wa chitsulo chosapanga dzimbiri ndi chitsulo chosagwira kutentha | |

| ASME | ASME SA564/SA693/SA705 | Zofananira zotengera ma code a chotengera cha pressure |

| AMS (Azamlengalenga) | Mtengo wa AMS5643 | Azamlengalenga spec kwa bala, waya, forgings, ndi mphete mu 17-4PH yankho mankhwala ndi okalamba |

| Mtengo wa AMS5622 | Mbale, pepala, ndi mizere | |

| EN / DIN | EN 1.4542 / DIN X5CrNiCuNb16-4 | Matchulidwe aku Europe a 17-4PH okhala ndi mawonekedwe ofanana ndi katundu |

| UNS | UNS S17400 | Dzina la Unified Numbering System |

| ISO | ISO 15156-3 | Kuyenerera kugwiritsa ntchito zida zamafuta m'malo opangira mpweya wowawasa |

| NACE | MR0175 | Zofunikira pakukana kupsinjika kwa sulfide |

| Chifukwa Chosankha Ife : |

1. Mutha kupeza zinthu zabwino kwambiri malinga ndi zomwe mukufuna pamtengo wotsika kwambiri.

2. Timaperekanso Reworks, FOB, CFR, CIF, ndi mitengo yobweretsera khomo ndi khomo. Tikukulangizani kuti mugwiritse ntchito zotumiza zomwe zingakhale zotsika mtengo.

3. Zida zomwe timapereka ndizotsimikizika kotheratu, kuyambira pa chiphaso choyezera zinthu mpaka pachiwonetsero chomaliza. (Malipoti awonetsa pakufunika)

4. e chitsimikizo kupereka yankho mkati 24hours(nthawi zambiri mu ola lomwelo)

5. Mutha kupeza njira zina zogulitsira, zoperekera mphero ndikuchepetsa nthawi yopanga.

6. Ndife odzipereka kwathunthu kwa makasitomala athu. Ngati sizingatheke kukwaniritsa zomwe mukufuna mutapenda zonse zomwe mungasankhe, sitidzakusocheretsani popanga malonjezo abodza omwe angapangitse ubale wabwino ndi makasitomala.

| Chitsimikizo cha Ubwino cha SAKY STEEL (kuphatikiza zonse Zowononga ndi Zosawononga) |

1. Mayeso a Visual Dimension

2. Kuwunika kwamakina monga kukhazikika, kutalika ndi kuchepetsa dera.

3. Akupanga mayeso

4. Kusanthula kwa mankhwala

5. Mayeso olimba

6. Kuyesa kwachitetezo cha pitting

7. Mayeso Olowera

8. Intergranular Corrosion Testing

9. Kusanthula zotsatira

10. Metallography Experimental Test

| Kupaka |

1. Kulongedza ndi kofunika kwambiri makamaka ngati katundu wapadziko lonse lapansi amadutsa munjira zosiyanasiyana kuti akafike komwe akupita, chifukwa chake timayika chidwi chapadera pakuyika.

2. Saky Steel's amanyamula katundu wathu m'njira zambiri kutengera zomwe timapanga. Timanyamula katundu wathu m'njira zingapo, monga,

17-4PH, 630 ndi X5CrNiCuNb16-4 / 1.4542 imaperekedwa mwa mawonekedwe a mipiringidzo yozungulira, mapepala, mipiringidzo yathyathyathya ndi mzere wozizira. Zinthuzi zimagwiritsidwa ntchito kwambiri muzamlengalenga, m'madzi, pamapepala, mphamvu, m'mphepete mwa nyanja ndi m'mafakitale azakudya pazinthu zamakina olemetsa, ma bushings, masamba opangira turbine, zomangira, zomangira, zitsulo zoyendetsa, mtedza, zida zoyezera.

1. Aerospace Industry

-

Zida za injini ya turbine (ma impellers, shafts, housings)

-

Zigawo zoyatsira

-

Zomangira (maboliti, mtedza) ndi zolumikizira zomangamanga

-

Zigawo za hydraulic system

2. Makampani a Mafuta ndi Gasi

-

Zida zolowera pansi (zobowola, mipando ya valve, zopangira mapaipi)

-

Zigawo za mavavu zolimbana ndi dzimbiri

-

Zida zamafuta opangira mafuta (pampu shafts, nyumba, mphete zosindikizira)

3. Chemical Processing Viwanda

-

Mapampu ndi ma valve omwe amagwiritsidwa ntchito m'malo acidic

-

Zosintha kutentha ndi zotengera zokakamiza

-

Ma reactors ndi ma agitator shafts

-

Zopangira matanki osungira

4. Kukonza Chakudya & Zida Zachipatala

-

Zakudya zamagulu opangira zakudya komanso zigawo zoyendetsa

-

Zigawo za ma sterilizer amphamvu kwambiri

-

Zida zopangira opaleshoni ndi zida zamankhwala (chiphaso chofunikira)

-

Magawo a machitidwe owongolera kuthamanga kwachipatala

5. Marine ndi Offshore Engineering

-

Zopangira ma propeller ndi ma propulsion assemblies

-

Mapampu amadzi am'nyanja ndi zigawo zosindikizira

-

Zomangamanga ndi zolumikizira zomangira m'mabwalo azombo

-

Zida zolimbana ndi dzimbiri zamapulatifomu akunyanja

6. Kupanga Mphamvu za Nyukiliya ndi Mphamvu

-

Zomangira za zida zanyukiliya

-

Ma chubu amathandizira pazosinthira kutentha

-

Ma hydraulic valve ndodo ndi matupi apompo

-

Zigawo za valve zotentha kwambiri

7. Makampani a Mold ndi Zida

-

Mafelemu a jekeseni nkhungu

-

Kupanga mashafts ndi zothandizira zamphamvu kwambiri

-

Atsogolereni nsanamira ndi zitsamba zomangirira matabwa

8. General Machinery & Automation

-

Zida zotumizira monga ma giya ma shafts, ma couplings, ndi ma spindles

-

Njanji zamakina ndi ndodo zoyikira m'makina a automation

-

Industrial hydraulic piston rods