17-4PH 630 Ibha Yensimbi Engagqwali

Incazelo emfushane:

I-SAKYSTEEL ihlinzeka ngamabha ensimbi engagqwali angu-17-4PH (630) anamandla amakhulu kanye nokumelana nokugqwala kwe-aerospace, olwandle, kanye nokusetshenziswa kwezimboni.

I-Saky Steel's 17-4PH / 630 / 1.4542 ingenye yezinsimbi ezingenasici ze-chromium-nickel alloy ethandwa kakhulu futhi evame ukusetshenziswa kakhulu enesengezo sethusi, imvula eqiniswe ngesakhiwo se-martensitic. Ibonakala ngokumelana nokugqwala okuphezulu ngenkathi igcina izakhiwo zamandla aphezulu, kufaka phakathi ubulukhuni. Insimbi ingasebenza ebangeni lokushisa ukusuka -29 ℃ kuya ku-343 ℃, kuyilapho igcina amapharamitha amahle kakhulu. Ngaphezu kwalokho, izinto ezikuleli banga zibonakala nge-ductility enhle futhi ukumelana nokugqwala kwazo kuqhathaniswa ne-1.4301 / X5CrNi18-10.

I-17-4PH, eyaziwa nangokuthi i-UNS S17400, iyinsimbi engagqwali eqinile enemvula ye-martensitic. Kuyinto eguquguqukayo futhi esetshenziswa kabanzi ezimbonini ezahlukahlukene, njenge-aerospace, nuclear, petrochemical, kanye nokucubungula ukudla.

I-17-4PH inamandla aphezulu, ukumelana nokugqwala okuhle, nobulukhuni obuhle uma kuqhathaniswa nezinye izinsimbi ezingenasici. Ingxube ye-chromium engu-17%, i-nickel engu-4%, ithusi engu-4%, nenani elincane le-molybdenum ne-niobium. Ukuhlanganiswa kwalezi zakhi kunikeza insimbi izici zayo eziyingqayizivele.

Sekukonke, i-17-4PH iwumsebenzi oguquguqukayo futhi owusizo onikeza ibhalansi enhle yezakhiwo zohlu olubanzi lwezinhlelo zokusebenza.

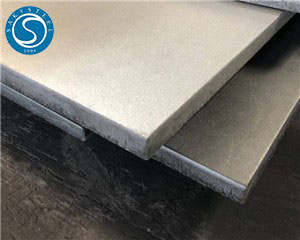

| Umbukiso Wemikhiqizo Ekhanyayo Yebha Yensimbi Engagqwali: |

| Imininingwane ye-630insimbi engagqwali bar: |

Imininingwane :I-ASTM A564/ASME SA564

Ibanga:AISI 630 SUS630 17-4PH 1.4542 PH

Ubude :5.8M, 6M nobude obudingekayo

Ububanzi Bebha Eyindilinga :4.00 mm kuya ku-400 mm

Ibha Elikhanyayo :4mm - 100mm,

Ukubekezela :I-H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 noma ngokwezidingo zekhasimende ngalinye

Isimo :Okubandayo Okudwetshiwe & Okupholishiwe Okubandayo Okudwetshiwe, Okuhlutshiwe futhi Kwakhiwe

I-Surface Finish :Mnyama, Ogqamile, Opholishiwe, Oguqukile Omabi, NO.4 Qeda, Math Qeda

Ifomu :Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged Njll.

Qeda :I-Plain End, I-Beveled End

| Ibha Yensimbi Engagqwali Amabanga Ukwakhiwa Kwamakhemikhali: |

| Ukuqokwa kwe-UNS | Uhlobo | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Ezinye Izinto |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 | 630 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 15.00–17.50 | 3.00–5.00 | - | - | - | 3.00–5.00 | C |

| S17700 | 631 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–18.00 | 6.50–7.75 | - | - | - | - | - |

| S15700 | 632 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–16.00 | 6.50–7.75 | - | 2.00–3.00 | - | - | - |

| S35500 | 634 | 0.10–0.15 | 0.50–1.25 | 0.040 | 0.030 | 0.50 | 15.00–16.00 | 4.00–5.00 | - | 2.50–3.25 | - | - | D |

| S17600 | 635 | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–17.50 | 6.00–7.50 | 0.40 | - | - | - | - |

| S15500 | I-XM-12 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–15.50 | 3.50–5.50 | - | - | - | 2.50–4.50 | C |

| S13800 | I-XM-13 | 0.05 | 0.20 | 0.040 | 0.008 | 1.00 | 12.25–13.25 | 7.50–8.50 | 0.90–1.35 | 2.00–2.50 | - | - | E |

| S45500 | I-XM-16 | 0.03 | 0.50 | 0.015 | 0.015 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 0.90–1.40 | 1.50–2.50 | F |

| S45503 | - | 0.010 | 0.50 | 0.010 | 0.010 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 1.00–1.35 | 1.50–2.50 | F |

| S45000 | I-XM-25 | 0.05 | 1.00 | 0.030 | 0.030 | 0.50 | 14.00–16.00 | 5.00–7.00 | - | - | - | 1.25–1.75 | G |

| S46500 | - | 0.02 | 0.25 | 0.040 | 0.030 | 1.00 | 11.00–13.0 | 10.75–11.25 | 0.15–0.50 | 0.75–1.25 | - | - | E |

| S46910 | - | 0.030 | 1.00 | 0.040 | 0.020 | 1.00 | 11.00–12.50 | 8.00–10.00 | 0.50–1.20 | 3.0–5.0 | - | 1.5–3.5 | - |

| I-S10120 | - | 0.02 | 1.00 | 0.040 | 0.015 | 0.25 | 11.00–12.50 | 9.00–11.00 | 1.10 | 1.75–2.25 | 0.20–0.50 | - | E |

| I-S11100 | - | 0.02 | 0.25 | 0.040 | 0.010 | 0.25 | 11.00–12.50 | 10.25–11.25 | 1.35–1.75 | 1.75–2.25 | 0.20–0.50 | - | E |

| 17-4PH Amabanga Alinganayo Ebha Yensimbi Engagqwali: |

| IZINGA | I-UNS | I-WERKSTOFF NR. | AFNOR | I-JIS | EN | BS | I-GOST |

| 17-4PH | S17400 | 1.4542 |

| 17-4PH Ukwelashwa Kwesixazululo Sebha Engenasici: |

| Ibanga | Amandla E-Tensile (MPa) min | Ubude (% ku-50mm) min | Amandla Esivuno 0.2% Ubufakazi (MPa) min | Ukuqina | |

| I-Rockwell C max | I-Brinell (HB) ubuningi | ||||

| 630 | - | - | - | 38 | 363 |

Phawula kabusha: Isimo A 1900±25°F[1040±15°C](sipholile njengoba kudingeka sibe ngaphansi kuka-90°F(30°C))

1.4542 Izidingo Zokuhlolwa Kwemishini Ngemva Kokwelashwa Kokushisa Okuqina Ubudala:

Amandla Okuqina :Iyunithi – ksi (MPa) , Ubuncane

I-Yeild Strength :0.2 % Offset , Iyunithi – ksi (MPa) , Ubuncane

Elongation :ku-2″, Iyunithi : % , Ubuncane

Ukuqina :Rockwell, Maximum

17-4PH Izakhiwo Zensimbi Engagqwali ngeSimo Sokwelapha Ukushisa:

| H900 | H925 | H 1025 | H 1075 | H 1100 | H 1150 | H 1150-M | |

| Amandla Okuqina Okuqinile, ksi | 190 | 170 | 155 | 145 | 140 | 135 | 115 |

| 0.2% Amandla Esivuno, ksi | 170 | 155 | 145 | 125 | 115 | 105 | 75 |

| Ubude % ku-2″ noma ku-4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Ukunciphisa Indawo, % | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Ukuqina, uBrinell (Rockwell) | 388 (C 40) | 375 (C 38) | 331 (C 35) | 311 (C 32) | 302 (C 31) | 277 (C 28) | 255 (C 24) |

| Impact Charpy V-Notch, ft – lbs | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Inketho yokuncibilika: |

1 EAF: Isithando somlilo se-Electric Arc

2 I-EAF+LF+VD: Ukuncibilika okucolisisiwe nokususa umoya nge-vacuum

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: umoya ovikelayo I-Electro Slag Remelting

5 VIM+PESR: Ukuncibilika kokufakwa kwevacuum

| Inketho yokwelapha ukushisa: |

1 +A: I-Annealed (igcwele/ithambile/i-spheroidizing)

2 +N: Kwenziwa ngokujwayelekile

I-3 +NT: Ijwayelekile futhi iqinile

I-4 +QT: Icinywe futhi ithambile (amanzi/amafutha)

5 +AT: Isixazululo sinqanyuliwe

6 +P: Imvula iqinile

| Ukwelashwa Kokushisa: |

Ukwelashwa kwesixazululo (Isimo A) — Izinsimbi ezingenasici zeBanga 630 zishisisa ku-1040°C amahora angu-0.5, bese zipholiswa ngomoya zibe ngu-30°C. Izingxenye ezincane zala mabanga zingacinywa ngamafutha.

Ukuqina - Izinsimbi ezingenasici zeBanga 630 ziqiniswa ngobudala emazingeni okushisa aphansi ukuze kuzuzwe izakhiwo ezidingekayo. Phakathi nenqubo, ukushintsha kombala okukha phezulu kwenzeka kulandele ukushwabana ku-0.10% esimweni H1150, kanye no-0.05% esimweni H900.

| Amazinga we-17-4PH Yensimbi Engagqwali |

I-17-4PH insimbi engagqwali ihambisana nenani elibanzi lamazinga omhlaba kanye nokucaciswa kwayo, iqinisekisa ikhwalithi ethembekile nokusebenza kuzo zonke izimboni ezifana ne-aerospace, amandla, nokucubungula amakhemikhali.

| Inhlangano Ejwayelekile | Ukucaciswa | Incazelo |

|---|---|---|

| I-ASTM | I-ASTM A564 / A564M | Okujwayelekile kwamabha ensimbi engenasici agqinqiwe ashisayo futhi aqedwe ukubanda aqedwe |

| I-ASTM A693 | Ukucaciswa kwezulu-ukuqinisa ipuleti lensimbi engagqwali, ishidi, kanye nomugqa | |

| I-ASTM A705 / A705M | Ukucaciswa kwemvula eyenziwe lukhuni-iqinisa insimbi engagqwali kanye nensimbi ekwazi ukumelana nokushisa | |

| ASME | ASME SA564 / SA693 / SA705 | Izicaciso zekhodi yomkhumbi ocindezelayo olinganayo |

| I-AMS (Aerospace) | I-AMS 5643 | I-Aerospace spec yebha, intambo, ama-forging, namaringi ku-17-4PH eselashwe ngesixazululo futhi yandala |

| I-AMS 5622 | Ipuleti, ishidi, kanye nomdweshu | |

| EN / DIN | EN 1.4542 / DIN X5CrNiCuNb16-4 | Ukuqokwa kwaseYurophu kwe-17-4PH enokwakheka okufanayo nezici |

| I-UNS | I-UNS S17400 | Ukuqokwa Kwesistimu Yezinombolo Ehlanganisiwe |

| ISO | ISO 15156-3 | Ukufaneleka kokusetshenziswa kumishini ye-oilfield ezindaweni zegesi emuncu |

| I-NACE | MR0175 | Isidingo esibonakalayo sokumelana nokuqhekeka kwengcindezi ye-sulfide |

| Kungani Ukhetha Thina : |

1. Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani inani elingenzeka.

2. Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokudiliva umnyango nomnyango. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

3. Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina.(Imibiko izovela ngokwemfuneko)

4. isiqinisekiso sokunikeza impendulo phakathi namahora angu-24(imvamisa ngehora elifanayo)

5. Ungathola ezinye izindlela zesitoko, ukulethwa komshini ngokunciphisa isikhathi sokukhiqiza.

6. Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

| Ukuqinisekiswa Kwekhwalithi Ye-SAKY STEEL (okuhlanganisa kokubili Okubhubhisayo Nokungabhubhisi) |

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Ukuhlolwa kwe-Ultrasonic

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Ukuhlolwa Okungenele

8. I-Intergranular Corrosion Testing

9. Ukuhlaziywa komthelela

10. Ukuhlolwa Kokuhlola Kwe-Metallography

| Ukupakisha |

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho izimpahla zidlula eziteshini ezihlukahlukene ukuze zifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakishwa.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,

I-17-4PH, 630 kanye ne-X5CrNiCuNb16-4 / 1.4542 inikezwa ngesimo semigoqo eyindilinga, amashidi, imigoqo eyisicaba kanye nomugqa ogoqeke obandayo. Izinto ezisetshenziswayo zisetshenziswa kakhulu ku-aerospace, zasolwandle, zamaphepha, zamandla, ezisogwini nezimboni zokudla ezingxenyeni zomshini osindayo, ama-bushings, ama-turbine blades, ama-couplings, izikulufu, ama-drive shafts, amantongomane, nemishini yokulinganisa.

1. Imboni ye-Aerospace

-

Izingxenye zenjini ye-turbine (i-impellers, shafts, izindlu)

-

Izingxenye zegiya lokufika

-

Izixhumi (amabhawodi, amantongomane) nezixhumi zesakhiwo

-

Izingxenye zesistimu ye-Hydraulic

2. Imboni kawoyela negesi

-

Amathuluzi e-Downhole (izinduku zokubhoboza, izihlalo zamavalvu, izifakelo zamapayipi)

-

Izingxenye zamavalvu ezimelana nokubola

-

Izingxenye zemishini ye-Oilfield (i-pump shafts, izindlu, izindandatho zokuvala)

3. Imboni Yokucubungula Amakhemikhali

-

Amaphampu nama-valve asetshenziswa ezindaweni ezine-asidi

-

Izishintshi zokushisa nemikhumbi yokucindezela

-

Ama-reactors nama-agitator shafts

-

Ukufakwa amathangi okugcina

4. Ukucutshungulwa Kokudla Nezisetshenziswa Zezokwelapha

-

Isikhunta sezinga lokudla kanye nezingxenye zokushayela

-

Izingxenye zama-sterilizer anengcindezi ephezulu

-

Amathuluzi okuhlinza namathuluzi ezokwelapha (kudingeka isitifiketi)

-

Izingxenye zezinhlelo zokulawula ingcindezi yezokwelapha

5. Ubunjiniyela Basolwandle Nasolwandle

-

Ama-propeller shafts nama-propulsion assemblies

-

Ama-shaft wepompo yamanzi olwandle kanye nezingxenye zokuvala

-

Izixhumi nezixhumi zesakhiwo ezindaweni zemikhumbi

-

Izingxenye ezimelana nokubola kwezinkundla zasolwandle

6. Ukukhiqizwa Kwenuzi kanye Namandla

-

Izixhumi zezakhiwo ze-nuclear reactor

-

I-Tube bundle isekela izishintshi zokushisa

-

Ama-valve e-hydraulic kanye nemizimba yepompo

-

Izingxenye zama-valve ezisezingeni eliphezulu

7. Imboni Yesikhunta kanye Nezinsimbi

-

Amafreyimu esikhunta sokujova

-

Amandla aphezulu okwenza shafts nezisekelo

-

Qondisa izigxobo kanye nezihlahla zokubumba izitembu

8. Imishini Ejwayelekile & Okuzenzakalelayo

-

Izingxenye zokudlulisela njengamagiya shaft, ama-couplings, nama-spindles

-

Ojantshi bemishini nezinduku zokubeka endaweni kumasistimu ezishintshayo

-

Izinti ze-piston ze-industrial hydraulic