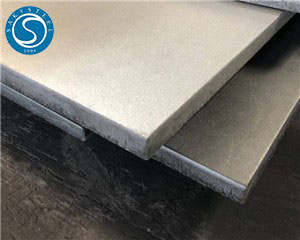

17-4PH 630 Bakin Karfe Bar

Takaitaccen Bayani:

SAKYSTEEL yana ba da sandunan bakin karfe 17-4PH (630) tare da kyakkyawan ƙarfi da juriya na lalata don sararin samaniya, ruwa, da amfani da masana'antu

Saky Steel's 17-4PH / 630 / 1.4542 yana ɗaya daga cikin shahararrun kuma mafi yawan amfani da bakin karfe na chromium-nickel gami da ƙari na jan karfe, hazo mai taurare tare da tsarin martensitic. An kwatanta shi da babban juriya na lalata yayin da yake riƙe manyan kaddarorin ƙarfi, gami da taurin. Karfe na iya aiki a cikin kewayon zafin jiki daga -29 ℃ zuwa 343 ℃, yayin da yake riƙe da ingantattun sigogi. Bugu da kari, kayan da ke cikin wannan darajojin suna da siffa da ingantacciyar ductility kuma juriyar lalatarsu tana kwatankwacin 1.4301 / X5CrNi18-10.

17-4PH, wanda kuma aka sani da UNS S17400, hazo ne mai taurin bakin karfe. Abu ne da ya dace kuma ana amfani da shi sosai a masana'antu daban-daban, kamar sararin samaniya, nukiliya, sinadarin petrochemical, da sarrafa abinci.

17-4PH yana da ƙarfi mai ƙarfi, juriya mai kyau, da taurin mai kyau idan aka kwatanta da sauran bakin karfe. Cakuda ne na 17% chromium, 4% nickel, 4% jan karfe, da ƙaramin adadin molybdenum da niobium. Haɗin waɗannan abubuwan yana ba wa ƙarfe kayansa na musamman.

Gabaɗaya, 17-4PH abu ne mai mahimmanci kuma mai amfani wanda ke ba da ma'auni mai kyau na kaddarorin don aikace-aikacen da yawa.

| Bakin Karfe Round Bar Bright Products Nuna: |

| Bayanan Bayani na 630bakin karfe mashaya: |

Ƙayyadaddun bayanai:ASTM A564 / ASME SA564

Daraja:AISI 630 SUS630 17-4PH 1.4542 PH

Tsawon:5.8M, 6M & Tsawon Da ake Bukata

Diamita Mai Zagaye:4.00 mm zuwa 400 mm

Bar Bar :4mm - 100mm,

Haƙuri:H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 ko kamar yadda abokan ciniki' bukatun

Sharadi:Sanyi Zane & Goge Sanyi Zane, Bawon & Ƙarfafa

Ƙarshen Sama:Baƙar fata, Mai haske, Goge, Juya mai kauri, NO.4 Gama, Matt Gama

Form:Zagaye, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged Da dai sauransu.

Ƙarshe:Ƙarshen Ƙarshe, Ƙarshen Ƙarshe

| Bakin Karfe Bar Maki Makin Sinadari: |

| Tsarin UNS | Nau'in | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Sauran Abubuwan |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 | 630 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 15.00-17.50 | 3.00-5.00 | - | - | - | 3.00-5.00 | C |

| S17700 | 631 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00-18.00 | 6.50-7.75 | - | - | - | - | - |

| S15700 | 632 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00-16.00 | 6.50-7.75 | - | 2.00-3.00 | - | - | - |

| S35500 | 634 | 0.10-0.15 | 0.50-1.25 | 0.040 | 0.030 | 0.50 | 15.00-16.00 | 4.00-5.00 | - | 2.50-3.25 | - | - | D |

| S17600 | 635 | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00-17.50 | 6.00-7.50 | 0.40 | - | - | - | - |

| S15500 | XM-12 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00-15.50 | 3.50-5.50 | - | - | - | 2.50-4.50 | C |

| S13800 | XM-13 | 0.05 | 0.20 | 0.040 | 0.008 | 1.00 | 12.25-13.25 | 7.50-8.50 | 0.90-1.35 | 2.00-2.50 | - | - | E |

| S45500 | XM-16 | 0.03 | 0.50 | 0.015 | 0.015 | 0.50 | 11.00-12.50 | 7.50-9.50 | - | 0.50 | 0.90-1.40 | 1.50-2.50 | F |

| S45503 | - | 0.010 | 0.50 | 0.010 | 0.010 | 0.50 | 11.00-12.50 | 7.50-9.50 | - | 0.50 | 1.00-1.35 | 1.50-2.50 | F |

| S45000 | XM-25 | 0.05 | 1.00 | 0.030 | 0.030 | 0.50 | 14.00-16.00 | 5.00-7.00 | - | - | - | 1.25-1.75 | G |

| S46500 | - | 0.02 | 0.25 | 0.040 | 0.030 | 1.00 | 11.00-13.0 | 10.75-11.25 | 0.15-0.50 | 0.75-1.25 | - | - | E |

| S46910 | - | 0.030 | 1.00 | 0.040 | 0.020 | 1.00 | 11.00-12.50 | 8.00-10.00 | 0.50-1.20 | 3.0-5.0 | - | 1.5-3.5 | - |

| S10120 | - | 0.02 | 1.00 | 0.040 | 0.015 | 0.25 | 11.00-12.50 | 9.00-11.00 | 1.10 | 1.75-2.25 | 0.20-0.50 | - | E |

| S11100 | - | 0.02 | 0.25 | 0.040 | 0.010 | 0.25 | 11.00-12.50 | 10.25-11.25 | 1.35-1.75 | 1.75-2.25 | 0.20-0.50 | - | E |

| 17-4PH Bakin Karfe Bar Kwatankwacin Maki: |

| STANDARD | UNS | Ayyukan Aiki NR. | AFNOR | JIS | EN | BS | GOST |

| 17-4PH | S17400 | 1.4542 |

| Magani Bakin Bar 17-4PH: |

| Daraja | Ƙarfin Tensile (MPa) min | Tsawaitawa (% a cikin 50mm) min | Ƙarfin Haɓaka 0.2% Hujja (MPa) min | Tauri | |

| Rockwell C max | Brinell (HB) max | ||||

| 630 | - | - | - | 38 | 363 |

Reamark: Yanayin A 1900± 25°F[1040±15°C](sanyi kamar yadda ake buƙata zuwa ƙasa da 90°F(30°C))

1.4542 Bukatun Gwajin Injiniyan Bayan Shekaru Taurin Jiyya:

Ƙarfin Ƙarfafawa:Unit – ksi (MPa), Mafi qaranci

Ƙarfin Jiki:0.2 % Kayyade , Unit – ksi (MPa) , Mafi ƙarancin

Tsawaitawa:a cikin 2″, Raka'a: % , Mafi ƙarancin

Tauri:Rockwell, mafi girma

17-4PH Bakin Karfe Kayayyakin Injini ta Yanayin Jiyya:

| H 900 | H 925 | H 1025 | H 1075 | H 1100 | H 1150 | H 1150-M | |

| Ƙarfin Ƙarfin Ƙarfi, ksi | 190 | 170 | 155 | 145 | 140 | 135 | 115 |

| 0.2% Ƙarfin Haɓaka, ksi | 170 | 155 | 145 | 125 | 115 | 105 | 75 |

| Tsawaita% a cikin 2 ″ ko 4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Rage Wuri, % | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Hardness, Brinell (Rockwell) | 388 (C 40) | 375 (C 38) | 331 (C 35) | 311 (C 32) | 302 (C 31) | 277 (C 28) | 255 (C 24) |

| Tasirin Charpy V-Notch, ft – lbs | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Zabin Narkewa: |

1 EAF: Tanderun Arc na Lantarki

2 EAF+LF+VD: Mai ladabi-smelting da vacuum degassing

3 EAF + ESR: Mai Rarraba Electro Slag

4 EAF + PESR: yanayi mai karewa Electro Slag Remelting

5 VIM+PESR: Vacuum induction narkewa

| Zaɓin maganin zafi: |

1 + A: Annealed (cikakken/laushi/spheroidizing)

2 +N: An daidaita

3 +NT: Daidaitacce da fushi

4 + QT: An kashe kuma mai zafi (ruwa / mai)

5 + AT: Magani an warware

6 +P: Hazo ya taurare

| Maganin zafi: |

Maganin Magani (Yanayin A) - Grade 630 bakin karfe suna mai zafi a 1040 ° C na 0.5 h, sannan a sanyaya iska zuwa 30 ° C. Ƙananan sassan waɗannan maki za a iya kashe mai.

Hardening - Grade 630 bakin karfe suna da shekaru-taurare a low yanayin zafi don cimma da ake bukata inji Properties. A yayin aiwatar da aikin, launin fata na zahiri yana faruwa tare da raguwa a 0.10% don yanayin H1150, da 0.05% don yanayin H900.

| Ma'auni don 17-4PH Bakin Karfe |

17-4PH bakin karfe ya dace da nau'ikan ka'idoji da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙasashen duniya, yana tabbatar da ingantaccen inganci da aiki a cikin masana'antu kamar sararin samaniya, makamashi, da sarrafa sinadarai.

| Standard Organization | Ƙayyadaddun bayanai | Bayani |

|---|---|---|

| ASTM | ASTM A564 / A564M | Madaidaicin sandunan ƙarfe da sifofi masu zafi da sanyin ƙarewa |

| ASTM A693 | Ƙididdiga don hazo-hardening bakin karfe farantin, takarda, da tsiri | |

| ASTM A705 / A705M | Ƙayyadaddun ƙayyadaddun ƙayyadaddun hazo-taurare bakin karfe da ƙirjin ƙarfe mai jure zafi | |

| ASME | ASME SA564/SA693/SA705 | Daidai madaidaicin lambar ƙayyadaddun lambar matsa lamba |

| AMS (Aerospace) | Farashin 5643 | Takaddun bayanai na Aerospace don mashaya, waya, ƙirƙira, da zobe a cikin maganin 17-4PH da aka bi da kuma masu tsufa |

| Farashin 5622 | Plate, takarda, da tsiri | |

| EN / DIN | EN 1.4542 / DIN X5CrNiCuNb16-4 | Ƙididdigar Turai don 17-4PH tare da irin wannan abun da ke ciki da kaddarorin |

| UNS | Saukewa: UNS17400 | Haɗin Kan Tsarin Lambobi |

| ISO | ISO 15156-3 | Cancantar amfani da kayan aikin mai a cikin mahalli mai tsami |

| NACE | Farashin 0175 | Abubuwan buƙatun don juriya ga faɗuwar damuwa na sulfide |

| Me yasa Zaba Mu: |

1. Kuna iya samun cikakkiyar kayan aiki bisa ga buƙatun ku aƙalla farashin mai yiwuwa.

2. Har ila yau, muna ba da Reworks, FOB, CFR, CIF, da ƙofar zuwa farashin bayarwa. Muna ba ku shawarar yin ciniki don jigilar kaya wanda zai zama mai fa'ida sosai.

3. Abubuwan da muke samarwa suna da tabbaci gaba ɗaya, tun daga takardar shaidar gwajin ɗanyen abu zuwa bayanin ƙimar ƙarshe. (Rahotanni za su nuna akan buƙata)

4. e garantin bayar da amsa a cikin sa'o'i 24 (yawanci a cikin sa'a guda)

5. Kuna iya samun madadin hannun jari, isar da niƙa tare da rage lokacin masana'antu.

6. Muna da cikakkiyar sadaukarwa ga abokan cinikinmu. Idan ba zai yiwu ba don biyan bukatun ku bayan nazarin duk zaɓuɓɓuka, ba za mu ɓatar da ku ta hanyar yin alkawuran ƙarya wanda zai haifar da kyakkyawar dangantakar abokan ciniki.

| Tabbacin Ingancin SAKY STEEL'S (ciki har da duka Mai lalacewa da mara lalacewa) |

1. Gwajin Girman gani

2. Injiniyan gwajin injiniya kamar tensile, Tsawaitawa da rage yanki.

3. Gwajin Ultrasonic

4. Binciken binciken kimiyya

5. Gwajin taurin

6. Gwajin kariyar rami

7. Gwajin shiga ciki

8. Gwajin Lalacewar Intergranular

9. Tasirin bincike

10. Gwajin Gwajin Metallography

| Marufi |

1. Yin kaya yana da matukar mahimmanci musamman a yanayin jigilar kayayyaki na duniya wanda jigilar kayayyaki ke bi ta hanyoyi daban-daban don isa wurin da ake nufi, don haka mun sanya damuwa ta musamman game da marufi.

2. Saky Steel's fakitin kayanmu ta hanyoyi da yawa dangane da samfuran. Muna tattara samfuran mu ta hanyoyi da yawa, kamar,

17-4PH, 630 da X5CrNiCuNb16-4 / 1.4542 ana bayar da su a cikin nau'i na sanduna zagaye, zanen gado, sanduna mai lebur da tsiri mai birgima. Ana amfani da kayan ko'ina a cikin sararin samaniya, ruwa, takarda, makamashi, teku da masana'antar abinci don kayan aikin injin mai nauyi, bushings, ruwan wukake, kayan haɗin gwiwa, sukurori, tudun tuƙi, kwayoyi, na'urori masu aunawa.

1. Masana'antar Aerospace

-

Abubuwan injin turbine (masu motsa jiki, shafts, gidaje)

-

sassan kayan saukarwa

-

Fasteners (kusoshi, kwayoyi) da tsarin haši

-

Na'ura mai aiki da karfin ruwa tsarin sassa

2. Masana'antar Mai da Gas

-

Kayan aikin saukarwa (sandunan hakowa, kujerun bawul, kayan aikin bututu)

-

sassan bawul masu jure lalata

-

Abubuwan da ake amfani da su a filin Oilfield (tushen famfo, gidaje, zoben rufewa)

3. Masana'antar sarrafa sinadarai

-

Pumps da bawuloli da ake amfani da su a cikin yanayin acidic

-

Masu musayar zafi da tasoshin matsa lamba

-

Reactors da agitator shafts

-

Kayan aiki don tankunan ajiya

4. Gudanar da Abinci & Kayan Aikin Lafiya

-

Kayan kayan abinci da abubuwan motsa jiki

-

Abubuwan da ake buƙata don sterilizers masu matsa lamba

-

Kayan aikin tiyata da kayan aikin likita (ana buƙatar takaddun shaida)

-

Sassan don tsarin kula da matsa lamba na likita

5. Injiniyan Ruwa da Ruwa

-

Matsakaicin magudanar ruwa da majalissar motsa jiki

-

Ruwan famfo ruwan teku da abubuwan rufewa

-

Fasteners da structural connectors a cikin guraben jirgi

-

Abubuwan da ke jure lalata don dandamali na ketare

6. Makamin Nukiliya da Samar da Wutar Lantarki

-

Fasteners don makaman nukiliya tsarin

-

Kunshin Tube yana tallafawa masu musayar zafi

-

Sandunan bawul na hydraulic da jikin famfo

-

Sassan bawul mai zafin jiki

7. Mold and Tooling Industry

-

Firam ɗin allura

-

Ƙarfin ƙarfi na kafa shafts da goyan baya

-

Jagora posts da bushings don stamping molds

8. Janar Injin & Automation

-

Abubuwan da ake watsawa kamar su ramukan gear, couplings, da spindles

-

Rails na injina da sandunan sakawa a cikin tsarin sarrafa kansa

-

Sandunan piston hydraulic masana'antu