17-4PH 630 Birta Aan-Aamiga ahayn

Sharaxaad Gaaban:

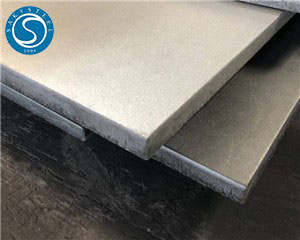

SAKYSTEEL waxay siisaa 17-4PH (630) baararka birta aan fiicnayn oo leh awood aad u fiican iyo iska caabin daxalka hawada, badda, iyo isticmaalka warshadaha

Saky Steel's 17-4PH / 630 / 1.4542 waa mid ka mid ah kuwa ugu caansan uguna caansan birta birta ah ee chromium-nickel alloy ee leh wax lagu daro naxaas, roobkuna wuxuu ku qallafsan yahay qaab-dhismeedka martensitic. Waxaa lagu gartaa caabbinta daxalka sare iyadoo la ilaalinayo sifooyinka xoogga sare, oo ay ku jiraan qallafsanaanta. Birtu waxay ku shaqayn kartaa inta u dhaxaysa -29 ℃ ilaa 343 ℃, iyada oo la ilaalinayo cabbirro aad u wanaagsan. Intaa waxaa dheer, qalabka fasalkaan waxaa lagu gartaa ductility yara wanaagsan iyo iska caabbinta daxalka waxay la mid tahay 1.4301 / X5CrNi18-10.

17-4PH, oo sidoo kale loo yaqaan UNS S17400, waa bir aan lahayn oo adkeynaysa roobab martensitic ah. Waa walxo badan oo si weyn looga isticmaalo warshadaha kala duwan, sida hawada hawada, nukliyeerka, petrochemical, iyo habaynta cuntada.

17-4PH waxay leedahay xoog sare, iska caabin daxalka wanaagsan, iyo engegan wanaagsan marka loo eego biraha kale ee aan nadiifka ahayn. Waa isku dhafka 17% chromium, 4% nikkel, 4% copper, iyo qadar yar oo molybdenum iyo niobium ah. Isku darka walxahan ayaa siinaya birta sifooyinkeeda gaarka ah.

Guud ahaan, 17-4PH waa walax aad u wanagsan oo faa'iido leh oo bixisa dheelitirnaan wanaagsan oo alaabooyin kala duwan ah.

| Alaabada Iftiiminaysa ee Wareega ah ee Birta Aanay Lahayn: |

| Tilmaamaha 630birta birta ah: |

TilmaamahaASTM A564 / ASME SA564

Darajo:AISI 630 SUS630 17-4PH 1.4542 PH

Dhererka:5.8M,6M & Dhererka Loo Baahan Yahay

Dhexroorka Bar Wareega:4.00 mm ilaa 400 mm

Baar dhalaalaya :4mm-100mm,

Dulqaad:H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 ama sida waafaqsan shuruudaha macaamiisha

Xaalad:Qabow la sawiray & Qabow la miiray oo la sawiray, diiray oo la been abuurtay

Dhamaystirka dusha sare:Madow, Iftiimin, Toostay, Rooneed qallafsan, NO.4 Dhammays, Matt dhammayn

Foomka:Wareeg, Square, Hex (A/F), leydi, Billet, Ingot, la been abuurtay IWM.

Dhammaad:Dhammaadka Cad, Dhammaadka Wacan

| Darajooyinka Baararka Birta Aan-la-aanta lahayn ee Kiimikada: |

| Magacaabidda UNS | Nooca | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Qaybaha Kale |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 | 630 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 15.00-17.50 | 3.00-5.00 | - | - | - | 3.00-5.00 | C |

| S17700 | 631 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00-18.00 | 6.50-7.75 | - | - | - | - | - |

| S15700 | 632 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00-16.00 | 6.50-7.75 | - | 2.00-3.00 | - | - | - |

| S35500 | 634 | 0.10-0.15 | 0.50-1.25 | 0.040 | 0.030 | 0.50 | 15.00-16.00 | 4.00-5.00 | - | 2.50-3.25 | - | - | D |

| S17600 | 635 | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00-17.50 | 6.00-7.50 | 0.40 | - | - | - | - |

| S15500 | XM-12 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00-15.50 | 3.50-5.50 | - | - | - | 2.50-4.50 | C |

| S13800 | XM-13 | 0.05 | 0.20 | 0.040 | 0.008 | 1.00 | 12.25-13.25 | 7.50-8.50 | 0.90-1.35 | 2.00-2.50 | - | - | E |

| S45500 | XM-16 | 0.03 | 0.50 | 0.015 | 0.015 | 0.50 | 11.00-12.50 | 7.50-9.50 | - | 0.50 | 0.90-1.40 | 1.50-2.50 | F |

| S45503 | - | 0.010 | 0.50 | 0.010 | 0.010 | 0.50 | 11.00-12.50 | 7.50-9.50 | - | 0.50 | 1.00-1.35 | 1.50-2.50 | F |

| S45000 | XM-25 | 0.05 | 1.00 | 0.030 | 0.030 | 0.50 | 14.00-16.00 | 5.00-7.00 | - | - | - | 1.25–1.75 | G |

| S46500 | - | 0.02 | 0.25 | 0.040 | 0.030 | 1.00 | 11.00-13.0 | 10.75-11.25 | 0.15-0.50 | 0.75–1.25 | - | - | E |

| S46910 | - | 0.030 | 1.00 | 0.040 | 0.020 | 1.00 | 11.00-12.50 | 8.00-10.00 | 0.50-1.20 | 3.0-5.0 | - | 1.5-3.5 | - |

| S10120 | - | 0.02 | 1.00 | 0.040 | 0.015 | 0.25 | 11.00-12.50 | 9.00-11.00 | 1.10 | 1.75–2.25 | 0.20-0.50 | - | E |

| S11100 | - | 0.02 | 0.25 | 0.040 | 0.010 | 0.25 | 11.00-12.50 | 10.25-11.25 | 1.35–1.75 | 1.75–2.25 | 0.20-0.50 | - | E |

| 17-4PH buundooyinka u dhigma ee birta aan birta lahayn: |

| HEERKA | UNS | SHAQADA NR. | AFNOR | JIS | EN | BS | GOST |

| 17-4PH | S17400 | 1.4542 |

| 17-4PH Daawaynta Xalka Baarka Aan Lahayn: |

| Darajo | Xoogga Jilitaanka (MPa) min | Ballaarinta (% gudaha 50mm) min | Xoogga Wax-soosaarka 0.2% Caddeynta (MPa) min | Adag | |

| Rockwell C max | Brinell (HB) ugu badnaan | ||||

| 630 | - | - | - | 38 | 363 |

Dib-u-eegis: Xaaladda A 1900± 25°F[1040±15°C](qabow sida looga baahan yahay in ka hooseeya 90°F(30°C))

1.4542 Shuruudaha Tijaabada Makaanikada Kadib Daawaynta Kulul Adkeynta:

Xoogga Jilitaanka:Unug – ksi (MPa), ugu yar

Xoogga Jidhka:0.2 % Dejinta , Cutub – ksi (MPa) , Ugu Yar

Kordhintagudaha 2″, Cutubka: % , Ugu Yar

Adag:Rockwell, ugu badnaan

17-4PH Guryaha Makaanikada Birta Ah Ee Aan Aan Lahayn ee Xaalada Daawaynta Kulaylka:

| H 900 | H 925 | H 1025 | H 1075 | H 1100 | H 1150 | H 1150-M | |

| Xoogga ugu dambeeya ee Tensile, ksi | 190 | 170 | 155 | 145 | 140 | 135 | 115 |

| 0.2% Xoogga Wax-soosaarka, ksi | 170 | 155 | 145 | 125 | 115 | 105 | 75 |

| Kordhinta % gudaha 2 ″ ama 4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Dhimista aagga, % | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Hardness, Brinell (Rockwell) | 388 (C 40) | 375 (C 38) | 331 (C 35) | 311 (C 32) | 302 (C 31) | 277 (C 28) | 255 (C 24) |

| Saamaynta Charpy V-Notch, ft - lbs | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Xulashada dhalada: |

1 EAF: Foornada Arc Koronto

2 EAF+LF+VD: dhalaalid la safeeyey iyo faakuum degeyska

3 EAF+ESR: Dib-u-soo-celinta Electro Slag

4 EAF+PESR: jawiga ilaalinta Electro Slag Remelting

5 VIM+PESR: dhalaalid fakium induction

| Xulashada kulaylka-daaweynta: |

1 +A: la jeexjeexay (buuxa/jilicsan/spheroidizing)

2 +N: Caadiyan

3 +NT: Caadiyan oo xanaaqsan

4 + QT: Demiyay oo xanaaqsan (biyo/saliid)

5 +AT: Xalka waa la tirtiray

6 +P: Da'ay wuu adkaaday

| Daawaynta Kulaylka: |

Daawaynta xalalka (Xaaladda A) - Fasalka 630 birta aan lahayn waxaa lagu kululeeyaa 1040 ° C 0.5 saac, ka dibna hawo qaboojiso ilaa 30 ° C. Qaybaha yaryar ee darajooyinkan waa la dami karaa saliid.

Adkeynta - Fasalka 630 birta aan-lahayn ayaa da'da lagu adkeeyey heerkulka hooseeya si loo gaaro sifooyinka farsamada ee loo baahan yahay. Inta lagu jiro habka, midab-baxa maqaarku wuxuu dhacaa oo ay ku xigto hoos u dhac 0.10% xaalad H1150, iyo 0.05% xaalad H900.

| Heerarka 17-4PH Birta Aan Lahayn |

17-4PH birta aan la taaban karin waxay u hoggaansantaa heerar kala duwan oo caalami ah iyo tilmaamo, hubinta tayada iyo waxqabadka la isku halayn karo ee warshadaha sida hawada, tamarta, iyo farsamaynta kiimikada.

| Ururka caadiga ah | Tilmaamid | Sharaxaada |

|---|---|---|

| ASTM | ASTM A564 / A564M | Heerarka kulayl-duuban iyo qabow-dhammeeyay ee da'da adkeynta baararka iyo qaababka birta aan fiicnayn |

| ASTM A693 | Cadaynta roobka-adkaynta saxan birta ah, xaashida, iyo xariijimaha | |

| ASTM A705 / A705M | Qeexitaanka roobka la sameeyay ee adkeynaya sida aan-lahayn iyo kulaylka u adkeysaneysa been-abuurka | |

| ASME | ASME SA564 / SA693 / SA705 | Tilmaamaha koodhka markabka cadaadiska u dhigma |

| AMS (Aerospace) | AMS 5643 | Aerospace spec ee baararka, siliga, foornada, iyo siddooyinka 17-4PH xal-la daweeyay oo da'doodu tahay |

| AMS 5622 | Saxan, xaashi, iyo xariijimo | |

| EN/DIN | EN 1.4542 / DIN X5CrNiCuNb16-4 | Magacaabista Yurub ee 17-4PH oo leh halabuur iyo astaamo la mid ah |

| UNS | UNS S17400 | Naqshadeynta Nidaamka Tirooyinka Midaysan |

| ISO | ISO 15156-3 | U qalmida isticmaalka qalabka saliida ee deegaanka gaaska dhanaan |

| NACE | MR0175 | Shuruudaha walxaha iska caabbinta dilaacsan walaaca sulfide |

| Maxaad noo doorataa: |

1. Waxaad heli kartaa alaabta ugu fiican ee waafaqsan shuruudahaaga ugu yaraan qiimaha suurtogalka ah.

2. Waxaan sidoo kale bixinaa Dib-u-shaqo, FOB, CFR, CIF, iyo albaabka ilaa albaabada qiimaha gaarsiinta. Waxaan kugula talineynaa inaad wax ka qabato dhoofinta kaas oo noqon doona mid dhaqaale badan.

3. Agabka aanu bixinayno gabi ahaanba waa la xaqiijin karaa, laga bilaabo shahaadada tijaabada alaabta ceeriin ilaa bayaan cabbirka kama dambaysta ah.

4. dammaanad qaado inaad ku bixiso jawaab 24saac gudahood (badanaa isla saacada)

5. Waxaad heli kartaa beddelka kaydka, keenista wax-shiidka oo yaraynaysa wakhtiga wax-soo-saarka.

6. Waxaan si buuxda ugu heellan nahay macaamiishayada. Haddii ay suurtagal noqon waydo inaad buuxiso shuruudahaaga ka dib markaad eegto dhammaan fursadaha, kuma marin habaabin doonno ballanqaadyo been abuur ah oo abuuraya xiriir wanaagsan oo macaamiisha ah.

| Xaqiijinta Tayada ee SAKY STEEL (oo ay ku jiraan kuwa wax baabi'iya iyo kuwa aan burburin labadaba) |

1. Tijaabada cabbirka muuqaalka

2. Baarista makaanikada sida xajinta, fidinta iyo dhimista aagga.

3. Baaritaanka Ultrasonic

4. Falanqaynta baaritaanka kiimikada

5. Imtixaan adag

6. Tijaabada ilaalinta godad

7. Tijaabada Gasha

8. Tijaabada Daxalka Dhexdhexaadka ah

9. Falanqaynta saamaynta

10. Tijaabada Tijaabada Metallography

| Baakadaha |

1. Baakayntu aad bay muhiim u tahay gaar ahaan marka ay dhacdo shixnado caalami ah oo shixnaduhu ay soo maraan waddooyin kala duwan si ay u gaadhaan meesha ugu dambaysa, sidaas awgeed waxaanu walaac gaar ah saarnay baakadaha.

2. Saky Steel's waxay alaabtayada u xirtaa siyaabo badan oo ku salaysan alaabta. Waxaan u badeshaa alaabtayada siyaabo badan, sida,

17-4PH, 630 iyo X5CrNiCuNb16-4 / 1.4542 waxaa lagu bixiyaa qaab baararka wareegsan, go'yaal, baararka fidsan iyo xariijimo qabow duuban. Qalabka waxaa si weyn loogu isticmaalaa hawada, badda, waraaqaha, tamarta, xeebaha iyo warshadaha cuntada ee qaybaha mashiinka culus, bushings, marawaxadaha marawaxadaha, isku-xidhka, boolal, ulaha wadista, nuts, qalabka cabbirka.

1. Warshadaha hawada sare

-

Qaybaha matoorka matoorka (mashiinnada, shafts, guryaha)

-

Qaybaha geerarka

-

Xidhiidhiyayaasha (bolts, nuts) iyo isku xidhayaasha qaab dhismeedka

-

Qaybaha nidaamka Haydarooliga

2. Warshadaha Shidaalka iyo Gaaska

-

Qalabka godka hoostiisa (Ulaha daloolista, kuraasta valve, qalabka tuubooyinka)

-

Qaybaha waalka daxalka u adkaysta

-

Qaybaha agabka saliida (qararka bambooyinka, guryaha, siddooyinka xidhida)

3. Warshadaha farsamaynta Kiimikada

-

Bambooyin iyo baallooyinka loo isticmaalo meelaha aashitada ah

-

Heerarka kulaylka iyo weelasha cadaadiska

-

Reactors iyo fallaadhaha kicinta

-

Qalabka lagu rakibo haamaha kaydinta

4. Nidaaminta Cuntada & Qalabka Caafimaadka

-

Qalabyada heerka-cuntada iyo qaybaha wadista

-

Qaybaha loogu talagalay jeermis dilayaasha cadaadis-sare

-

Qalab qalliin iyo qalab caafimaad (shahaadad ayaa loo baahan yahay)

-

Qaybaha hababka xakamaynta cadaadiska caafimaadka

5. injineernimada badda iyo badda

-

Shafts-propellers iyo ururrada kicinta

-

Ulaha bamka biyaha badda iyo qaybaha xidhidhiyaha

-

Xidhiidhiyayaasha iyo isku xidhayaasha qaab-dhismeedyada ee godadka markabka

-

Qaybaha u adkaysta daxalka ee meelaha xeebaha ka baxsan

6. Nukliyeerka iyo Korontada

-

Xidhiidhiyayaasha dhismayaasha reactor nukliyeerka

-

Xidhmada tubbada waxay taageertaa kulaylka beddelayaasha

-

Ulaha waalka Haydarooliga iyo maydadka bamka

-

Qaybaha waalka heerkulka sare

7. Warshada Caaryada iyo Qalabka

-

Qaababka caaryada la isku duro

-

Ulaha iyo taageerada samaynta xoogga sare

-

Hagaha dhejisyada iyo baadiyaha si loo shaabadeeyo caaryada

8. Mashiinada Guud & Automation

-

Qaybaha gudbinta sida shafts geerka, isku xidhka, iyo dunta dunta

-

Xadiidka makaanikada iyo ulaha meelaynta ee nidaamyada otomaatiga ah

-

Ulaha piston haydarooliga warshadaha