17-4PH 630 Ibha yentsimbi engatyiwa

Inkcazelo emfutshane:

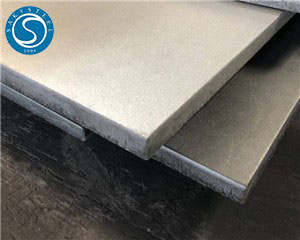

I-SAKYSTEEL ibonelela nge-17-4PH (630) imivalo yentsimbi engatyiwayo enamandla abalaseleyo kunye nokumelana nomhlwa kwi-aerospace, yaselwandle, kunye nokusetyenziswa kwemizi-mveliso.

I-Saky Steel's 17-4PH / 630 / 1.4542 yenye yezona zinto zithandwa kakhulu kwaye zisetyenziswa ngokuqhelekileyo i-stainless chromium-nickel alloy steels kunye ne-additive yobhedu, imvula eqinile kunye nesakhiwo se-martensitic. Ibonakaliswe ngokumelana okuphezulu kwe-corrosion ngelixa igcina iipropathi zamandla aphezulu, kubandakanya ubulukhuni. Intsimbi inokusebenza kuluhlu lobushushu ukusuka kwi -29 ℃ ukuya kwi-343 ℃, ngelixa igcina iiparamitha ezilungileyo. Ukongezelela, izinto ezikulo bakala zibonakaliswe ngokufanelekileyo kwi-ductility kwaye ukuxhathisa kwe-corrosion kuthelekiswa ne-1.4301 / X5CrNi18-10.

I-17-4PH, eyaziwa ngokuba yi-UNS S17400, yintsimbi ye-martensitic precipitation-hardening stainless steel. Yimathiriyeli eguquguqukayo kwaye isetyenziswa ngokubanzi kumashishini ahlukeneyo, anje nge-aerospace, inyukliya, i-petrochemical, kunye nokulungiswa kokutya.

I-17-4PH inamandla aphezulu, ukuxhathisa okulungileyo kokubola, kunye nobunzima obuhle xa kuthelekiswa nezinye iintsimbi ezingenasici. Ingumxube we-17% yechromium, i-4% ye-nickel, i-4% yobhedu, kunye nenani elincinci le-molybdenum kunye ne-niobium. Ukudibaniswa kwezi zinto kunika intsimbi iimpawu zayo ezizodwa.

Ngokubanzi, i-17-4PH yinto eninzi kakhulu kwaye iluncedo enika ibhalansi elungileyo yezakhiwo kuluhlu olubanzi lwezicelo.

| iStainless Steel Round Bar Iimveliso eziqaqambileyo: |

| Iimpawu ze630bar steel stainless: |

Iinkcukacha :I-ASTM A564 /ASME SA564

Ibakala:AISI 630 SUS630 17-4PH 1.4542 PH

Ubude :5.8M, 6M kunye noBubude obufunekayo

Ububanzi beBar eRound :4.00 mm ukuya kwi-400 mm

Ibha Eqaqambileyo :4mm - 100mm,

Ukunyamezela :H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 okanye ngokweemfuno zabathengi

Umqathango :Izotyiweyo ebandayo kunye neGold epholishiweyo izotywe, ixotyulwe kwaye yenziwe

Ukugqitywa komphezulu :Mnyama, Ukhazimle, Ukhazimlisiwe, Uguqukile Oburhabaxa, NO.4 Gqiba, Mat Gqiba

Ifom :Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged Etc.

Isiphelo :Isiphelo esicacileyo, iBeveled End

| Ibha yeNsimbi yeNsimbi yamaBanga ukuBunjwa kwemichiza: |

| Ukutyunjwa kwe-UNS | Uhlobo | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Ezinye izinto |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 | 630 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 15.00-17.50 | 3.00–5.00 | - | - | - | 3.00–5.00 | C |

| S17700 | 631 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–18.00 | 6.50–7.75 | - | - | - | - | - |

| S15700 | 632 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00-16.00 | 6.50–7.75 | - | 2.00–3.00 | - | - | - |

| S35500 | 634 | 0.10–0.15 | 0.50–1.25 | 0.040 | 0.030 | 0.50 | 15.00-16.00 | 4.00–5.00 | - | 2.50–3.25 | - | - | D |

| S17600 | 635 | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–17.50 | 6.00–7.50 | 0.40 | - | - | - | - |

| S15500 | XM-12 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–15.50 | 3.50–5.50 | - | - | - | 2.50–4.50 | C |

| S13800 | XM-13 | 0.05 | 0.20 | 0.040 | 0.008 | 1.00 | 12.25–13.25 | 7.50–8.50 | 0.90–1.35 | 2.00–2.50 | - | - | E |

| S45500 | XM-16 | 0.03 | 0.50 | 0.015 | 0.015 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 0.90–1.40 | 1.50–2.50 | F |

| S45503 | - | 0.010 | 0.50 | 0.010 | 0.010 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 1.00–1.35 | 1.50–2.50 | F |

| S45000 | XM-25 | 0.05 | 1.00 | 0.030 | 0.030 | 0.50 | 14.00-16.00 | 5.00–7.00 | - | - | - | 1.25–1.75 | G |

| S46500 | - | 0.02 | 0.25 | 0.040 | 0.030 | 1.00 | 11.00–13.0 | 10.75–11.25 | 0.15–0.50 | 0.75–1.25 | - | - | E |

| S46910 | - | 0.030 | 1.00 | 0.040 | 0.020 | 1.00 | 11.00–12.50 | 8.00–10.00 | 0.50–1.20 | 3.0–5.0 | - | 1.5–3.5 | - |

| S10120 | - | 0.02 | 1.00 | 0.040 | 0.015 | 0.25 | 11.00–12.50 | 9.00–11.00 | 1.10 | 1.75–2.25 | 0.20–0.50 | - | E |

| S11100 | - | 0.02 | 0.25 | 0.040 | 0.010 | 0.25 | 11.00–12.50 | 10.25–11.25 | 1.35–1.75 | 1.75–2.25 | 0.20–0.50 | - | E |

| I-17-4PH Ibha yeNsimbi eStainless amaBanga aLingeneyo: |

| UMGANGATHO | UNS | WERKSTOFF NR. | I-FNOR | I-JIS | EN | BS | IGOST |

| 17-4PH | S17400 | 1.4542 |

| I-17-4PH Unyango lweSisombululo seBar engenastainless: |

| IBanga | Amandla e-Tensile (MPa) min | Ubude (% kwi-50mm) min | Amandla eSivuno 0.2% Ubungqina (MPa) min | Ukuqina | |

| Rockwell C max | Brinell (HB) max | ||||

| 630 | - | - | - | 38 | 363 |

Inqaku lenqaku: Imeko A 1900±25°F[1040±15°C](ipholile njengoko kufuneka ngaphantsi kwe-90°F(30°C))

1.4542 IiMfuno zoVavanyo lweMechanical Emva koNyango loBubushushu lobudala:

Tensile strength :Iyunithi – ksi (MPa) , Ubuncinane

Yeild Amandla :0.2 % Offset , Iyunithi – ksi (MPa) , Ubuncinane

Elongation :ngo 2″, Iyunithi : % , Ubuncinane

Ukuqina :Rockwell, Ubuninzi

17-4PH iiPropathi zoomatshini beNsimbi eNgatyiwayo ngokweMeko yoNyango loBubushushu:

| H 900 | H 925 | H 1025 | H 1075 | H 1100 | H 1150 | H 1150-M | |

| Amandla okuqina okugqibelela, ksi | 190 | 170 | 155 | 145 | 140 | 135 | 115 |

| 0.2% Amandla eSivuno, ksi | 170 | 155 | 145 | 125 | 115 | 105 | 75 |

| Elongation % kwi2″ okanye 4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Ukuncipha kwendawo, % | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Ubunzima, uBrinell (Rockwell) | 388 (C 40) | 375 (C 38) | 331 (C 35) | 311 (C 32) | 302 (C 31) | 277 (C 28) | 255 (C 24) |

| Impembelelo Charpy V-Notch, ft – lbs | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Indlela Yokunyibilikisa: |

I-1 EAF: I-Electric Arc Furnace

I-2 EAF + LF + VD: Ukunyibilika okucokisekileyo kunye ne-vacuum degassing

3 EAF + ESR: Electro Slag Remelting

I-4 EAF + PESR: umoya wokukhusela i-Electro Slag Remelting

I-5 VIM + PESR: I-vacuum induction melting

| Ukhetho loNyango lobushushu: |

1 +A: I-Anelled (igcwele/ithambile/i-spheroidizing)

2 +N: Iqhelekile

3 +NT: Iqhelekile kwaye inomsindo

I-4 +QT: Icinyiwe kwaye ipholile (amanzi / ioli)

I-5 +AT: Isisombululo sivaliwe

6 +P: Imvula iqina

| Unyango loBubushushu: |

Unyango lwesisombululo (uMqathango A) - Iintsimbi zeBanga le-630 ezingenasici zifudunyezwa kwi-1040 ° C nge-0.5 h, emva koko zipholile emoyeni ukuya kwi-30 ° C. Amacandelo amancinci kula mabanga angacinywa ioli.

Ukuqina - iBanga le-630 i-stainless steels ilukhuni kwiqondo lokushisa eliphantsi ukuze kuphunyezwe iimpawu ezifunekayo zomatshini. Ngethuba lenkqubo, i-discoloration ebonakalayo iyenzeka ilandelwa yi-shrinkage kwi-0.10% kwimeko ye-H1150, kunye ne-0.05% yemeko ye-H900.

| Imigangatho ye-17-4PH yeNsimbi eNgatyiwayo |

I-17-4PH insimbi engenasici ihambelana noluhlu olubanzi lwemigangatho yamazwe ngamazwe kunye neenkcukacha, iqinisekisa umgangatho othembekileyo kunye nokusebenza kuwo wonke amashishini afana ne-aerospace, amandla, kunye nokulungiswa kweekhemikhali.

| Umbutho oMgangatho | Inkcazo | Inkcazo |

|---|---|---|

| I-ASTM | I-ASTM A564 / A564M | Umgangatho wemivalo yensimbi engenasici kunye neemilo ezishushu eziqengqelekayo nezibandayo |

| I-ASTM A693 | Ukucaciswa kwemvula-yenza lukhuni ipleyiti yentsimbi, icwecwe, kunye nomtya | |

| I-ASTM A705 / A705M | Ubalulo lokwenziwa kwemvula-ukuqina kwentsimbi engatyiwayo kunye nokumelana nobushushu | |

| ASME | ASME SA564 / SA693 / SA705 | Iimpawu zekhowudi yenqanawa yoxinzelelo olulinganayo |

| I-AMS (Isiphekepheke) | I-AMS 5643 | I-aerospace spec ye-bar, ucingo, i-forgings, kunye neeringi kwi-17-4PH isisombululo-sinyangwa kwaye sikhulile. |

| I-AMS 5622 | Ipleyiti, iphepha, kunye nomtya | |

| EN / DIN | EN 1.4542 / DIN X5CrNiCuNb16-4 | Ukutyunjwa kweYurophu kwi-17-4PH enokubunjwa okufanayo kunye neepropati |

| UNS | I-UNS S17400 | Ukutyunjwa kweNkqubo eManyeneyo yokuNika amanani |

| ISO | ISO 15156-3 | Ukufaneleka kokusetyenziswa kwizixhobo ze-oilfield kwiindawo zegesi ezimuncu |

| NACE | MR0175 | Imfuneko yezinto eziphathekayo zokumelana nokuqhekeka koxinzelelo lwesulfide |

| Kutheni Ukhetha Thina : |

1. Unokufumana izinto ezigqibeleleyo ngokwemfuno yakho ngexabiso elincinci elinokwenzeka.

2. Sikwabonelela ngeeReworks, FOB, CFR, CIF, kunye namaxabiso okuhanjiswa kweminyango. Sicebisa ukuba wenze isivumelwano sokuthumela ngenqanawe okuya kuba nokonga kakhulu.

3. Izinto esizibonelelayo zingqinisiseka ngokupheleleyo, ukusuka kwisatifikethi sovavanyo lwemathiriyeli ekrwada ukuya kwisiteyitimenti somgangatho wokugqibela.(Iingxelo ziya kubonisa ngokwemfuneko)

4. isiqinisekiso sokunika impendulo kwiiyure ezingama-24(ngokuqhelekileyo ngeyure enye)

5. Unokufumana ezinye iindlela zesitokhwe, ukuhanjiswa kwelitye kunye nokunciphisa ixesha lokuvelisa.

6. Sizinikezele ngokupheleleyo kubathengi bethu. Ukuba akunakwenzeka ukuhlangabezana neemfuno zakho emva kokuvavanya zonke iinketho, asiyi kukukhohlisa ngokwenza izithembiso zobuxoki eziza kudala ubudlelwane obuhle kubathengi.

| UQinisekiso loMgangatho lwe-SAKY STEEL (kubandakanywa zombini ezonakalisi nezingonakalisiyo) |

1. Uvavanyo lweDimension Visual

2. Uvavanyo lobuchwephesha olufana ne-tensile, Ukwandiswa kunye nokunciphisa indawo.

3. Uvavanyo lwe-ultrasonic

4. Uhlalutyo loviwo lwekhemikhali

5. Uvavanyo lokuqina

6. Uvavanyo lokukhuselwa komngxuma

7. Uvavanyo olungeneyo

8. Uvavanyo lwe-Intergranular Corrosion

9. Uhlalutyo lwempembelelo

10. Uvavanyo lweMetallography yoMfuniselo

| Ukupakishwa |

1. Ukupakisha kubaluleke kakhulu ngokukodwa kwimeko yokuthunyelwa kwamanye amazwe apho umthwalo udlula kwiitshaneli ezahlukeneyo ukuya kufika kwindawo yokugqibela, ngoko ke sibeka inkxalabo ekhethekileyo malunga nokupakishwa.

2. I-Saky Steel ipakisha iimpahla zethu ngeendlela ezininzi ezisekelwe kwiimveliso. Sipakisha iimveliso zethu ngeendlela ezininzi, ezinje,

I-17-4PH, i-630 kunye ne-X5CrNiCuNb16-4 / 1.4542 inikezelwa ngendlela yeebhari ezijikelezileyo, amaphepha, imivalo yeflethi kunye ne-cold-rolled strip. Izinto eziphathekayo zisetyenziswa ngokubanzi kwi-aerospace, i-marine, iphepha, amandla, i-offshore kunye namashishini okutya kumashishini omatshini onzima, iibhutsi, ii-turbine blades, i-couplings, izikrufu, i-drive shafts, amantongomane, izixhobo zokulinganisa.

1. Ishishini le-Aerospace

-

Amacandelo enjini ye-injini (i-impellers, shafts, housings)

-

Izixhobo zokumisa

-

Izibophelelo (iibholiti, iinati) kunye nezihlanganisi zesakhiwo

-

Amacandelo enkqubo yeHydraulic

2. Ishishini leoli negesi

-

Izixhobo zombhobho (iintonga zokubhola, izihlalo zevalvu, izifakelo zemibhobho)

-

Iindawo zevalvu ezikwaziyo ukubola

-

Amacandelo ezixhobo ze-oilfield (i-pump shafts, izindlu, amakhonkco okutywina)

3. Ishishini lokuLungisa imichiza

-

Iimpompo kunye neevalvu ezisetyenziswa kwiindawo ezineasidi

-

Izitshintshi zobushushu kunye neenqanawa zoxinzelelo

-

Ii-reactors kunye ne-agitator shafts

-

Izixhobo zokugcina iitanki

4. Ukwenziwa kokuTya kunye neZixhobo zoNyango

-

Iimolds zebakala lokutya kunye namacandelo okuqhuba

-

Amacandelo e-high-pressure sterilizers

-

Izixhobo zotyando kunye nezixhobo zonyango (isiqinisekiso siyafuneka)

-

Amacandelo eenkqubo zokulawula uxinzelelo lwezonyango

5. Ubunjineli baseLwandle kunye ne-Offshore

-

Ii-propeller shafts kunye ne-propulsion assemblies

-

Iimpompo zempompo zamanzi olwandle kunye namacandelo okutywinwa

-

Izibophelelo kunye nezihlanganisi zesakhiwo kwiinqanawa zeenqanawa

-

Amacandelo anganyangekiyo kukonakala kumaqonga aphesheya kolwandle

6. Inyukliya kunye nesiZukulwana saMandla

-

Izibophelelo zezakhiwo zereactor yenyukliya

-

I-Tube bundle ixhasa abatshintshi bobushushu

-

Iintsimbi zevalve ye-hydraulic kunye nemizimba yempompo

-

Iindawo zevalve yobushushu obuphezulu

7. Ishishini lokungunda kunye nezixhobo

-

Isakhelo sokungunda isitofu

-

Amandla aphezulu okwenza i-shafts kunye nenkxaso

-

Izithuba zesikhokelo kunye nezihlahla zokubumba isitampu

8. Oomatshini ngokuBanzi kunye noKuzenzekela

-

Amacandelo othumelo anje ngeeshafu zegiya, ukudityaniswa, kunye nezisongelo

-

Iintsimbi zoomatshini kunye neerodi zokubeka kwiinkqubo ezizenzekelayo

-

Iintsimbi zepiston ye-hydraulic hydraulic