17-4PH 630 igwe anaghị agba nchara

Nkọwa dị mkpirikpi:

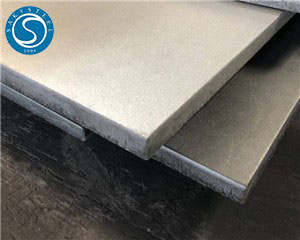

SAKYSTEEL na-enye ogwe igwe anaghị agba nchara 17-4PH (630) nwere ike dị mma na nguzogide corrosion maka ikuku, mmiri na ụlọ ọrụ mmepụta ihe.

Saky Steel's 17-4PH / 630 / 1.4542 bụ otu n'ime igwe anaghị agba nchara chromium-nickel alloy na-eji mgbakwunye ọla kọpa, mmiri ozuzo siri ike na usoro martensitic. A na-eji ya dị elu na-eguzogide corrosion ka ọ na-ejigide ihe ike dị elu, gụnyere ike. Steel nwere ike na-arụ ọrụ na okpomọkụ nso si -29 ℃ ka 343 ℃, ebe na-ejigide dịtụ mma parameters. Na mgbakwunye, ihe ndị dị na ọkwa a bụ ezigbo ductility mara mma yana nguzogide corrosion ha tụnyere 1.4301 / X5CrNi18-10.

17-4PH, nke a makwaara dị ka UNS S17400, bụ mmiri ozuzo na-eme ka igwe anaghị agba nchara. Ọ bụ ihe dị iche iche na nke a na-ejikarị eme ihe na ụlọ ọrụ dị iche iche, dị ka ikuku ikuku, nuklia, petrochemical, na nhazi nri.

17-4PH nwere ike dị elu, ezigbo nguzogide corrosion, na ike siri ike ma e jiri ya tụnyere igwe anaghị agba nchara ndị ọzọ. Ọ bụ ngwakọta nke 17% chromium, 4% nickel, 4% ọla kọpa, na obere ego nke molybdenum na niobium. Nchikota nke ihe ndị a na-enye ígwè ọrụ ya pụrụ iche.

N'ozuzu, 17-4PH bụ ihe na-agbanwe agbanwe na nke bara uru nke na-enye ezigbo nguzozi nke ihe onwunwe maka ọtụtụ ngwa ngwa.

| Igwe anaghị agba nchara gburugburu mmanya na-egbuke egbuke: |

| Nkọwapụta nke 630igwe anaghị agba nchara: |

Nkọwapụta:ASTM A564 / ASME SA564

Ọkwa:AISI 630 SUS630 17-4PH 1.4542 PH

Ogologo:5.8M,6M & Ogologo achọrọ

Dayameta Ogwe okirikiri:4.00 mm na 400 mm

Ogwe na-egbuke egbuke :4mm-100mm;

Nkwenye:H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 ma ọ bụ dị ka kwa ahịa 'chọrọ.

Ọnọdụ:Oyi adọtara na oyi na-egbu maramara adọtara, kpụchaa & kpụrụ akpụ

Mmecha elu:Ojii, na-egbuke egbuke, na-egbu maramara, Mgbanwe siri ike, NO.4 N'ikpeazụ, Matt mechaa

Ụdị:Gburugburu, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged etc.

Ọgwụgwụ:Ọgwụgwụ dị larịị, Ọgwụgwụ gbagọrọ agbagọ

| Ihe mejupụtara kemịkalụ igwe anaghị agba nchara: |

| Nhọpụta UNS | Ụdị | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Ihe ndị ọzọ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 | 630 | 0.07 | 1.00 | 0,040 | 0,030 | 1.00 | 15.00-17.50 | 3.00-5.00 | - | - | - | 3.00-5.00 | C |

| S17700 | 631 | 0.09 | 1.00 | 0,040 | 0,030 | 1.00 | 16.00-18.00 | 6.50–7.75 | - | - | - | - | - |

| S15700 | 632 | 0.09 | 1.00 | 0,040 | 0,030 | 1.00 | 14.00-16.00 | 6.50–7.75 | - | 2.00–3.00 | - | - | - |

| S35500 | 634 | 0.10–0.15 | 0.50–1.25 | 0,040 | 0,030 | 0,50 | 15.00-16.00 | 4.00–5.00 | - | 2.50–3.25 | - | - | D |

| S17600 | 635 | 0.08 | 1.00 | 0,040 | 0,030 | 1.00 | 16.00-17.50 | 6.00–7.50 | 0.40 | - | - | - | - |

| S15500 | XM-12 | 0.07 | 1.00 | 0,040 | 0,030 | 1.00 | 14.00-15.50 | 3.50–5.50 | - | - | - | 2.50–4.50 | C |

| S13800 | XM-13 | 0.05 | 0.20 | 0,040 | 0.008 | 1.00 | 12.25–13.25 | 7.50–8.50 | 0.90–1.35 | 2.00–2.50 | - | - | E |

| S45500 | XM-16 | 0.03 | 0,50 | 0.015 | 0.015 | 0,50 | 11.00-12.50 | 7.50–9.50 | - | 0,50 | 0.90–1.40 | 1.50–2.50 | F |

| S45503 | - | 0.010 | 0,50 | 0.010 | 0.010 | 0,50 | 11.00-12.50 | 7.50–9.50 | - | 0,50 | 1.00–1.35 | 1.50–2.50 | F |

| S45000 | XM-25 | 0.05 | 1.00 | 0,030 | 0,030 | 0,50 | 14.00-16.00 | 5.00–7.00 | - | - | - | 1.25–1.75 | G |

| S46500 | - | 0.02 | 0.25 | 0,040 | 0,030 | 1.00 | 11.00–13.0 | 10.75–11.25 | 0.15–0.50 | 0.75–1.25 | - | - | E |

| S46910 | - | 0,030 | 1.00 | 0,040 | 0.020 | 1.00 | 11.00-12.50 | 8.00-10.00 | 0.50–1.20 | 3.0–5.0 | - | 1.5–3.5 | - |

| S10120 | - | 0.02 | 1.00 | 0,040 | 0.015 | 0.25 | 11.00-12.50 | 9.00-11.00 | 1.10 | 1.75–2.25 | 0.20–0.50 | - | E |

| S11100 | - | 0.02 | 0.25 | 0,040 | 0.010 | 0.25 | 11.00-12.50 | 10.25–11.25 | 1.35–1.75 | 1.75–2.25 | 0.20–0.50 | - | E |

| 17-4PH igwe anaghị agba nchara akara akara: |

| Ọkọlọtọ | UNS | Ọrụ NR. | AFNOR | JIS | EN | BS | GOST |

| 17-4PH | S17400 | 1.4542 |

| Ọgwụgwọ Ọgwụ Igwe anaghị agba nchara 17-4PH: |

| Ọkwa | Ike Tensile (MPa) min | Mgbatị (% na 50mm) min | Mpụta Ike 0.2% Ihe akaebe (MPa) min | Isi ike | |

| Rockwell C max | Brinell (HB) kachasị | ||||

| 630 | - | - | - | 38 | 363 |

Nkwughachi: Ọnọdụ A 1900± 25°F[1040±15°C](dị jụụ dị ka achọrọ n'okpuru 90°F(30°C))

1.4542 chọrọ Nnwale Mechanical Mgbe Ọgwụgwọ Ọkụ Na-emesi Ike Ike:

Ike ọdụdọ :Nkeji – ksi (MPa), kacha nta

Ike Yeild:0.2 % kwụsịrị , nkeji – ksi (MPa) , kacha nta

Mgbatị:na 2″, nkeji:% , kacha nta

Isi ike:Rockwell, Kachasị

Njirimara igwe anaghị agba nchara 17-4PH site na ọnọdụ ọgwụgwọ okpomọkụ:

| H 900 | H 925 | H 1025 | H 1075 | H 1100 | H 1150 | H 1150-M | |

| Ike tensile kacha elu, ksi | 190 | 170 | 155 | 145 | 140 | 135 | 115 |

| 0.2% Ike Mpụta, ksi | 170 | 155 | 145 | 125 | 115 | 105 | 75 |

| Elongation% na 2″ ma ọ bụ 4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Mbelata Mpaghara,% | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Isi ike, Brinell (Rockwell) | 388 (C 40) | 375 (C 38) | 331 (C 35) | 311 (C 32) | 302 (C 31) | 277 (C 28) | 255 (C 24) |

| Mmetụta Charpy V-Notch, ft – lbs | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Nhọrọ agbaze: |

1 EAF: Igwe ọkụ ọkụ eletrik

2 EAF+LF+VD: Nnụcha-nzuzu na agụụ degassing

3 EAF+ ESR: Electro Slag Remelting

4 EAF + PESR: ikuku nchebe Electro Slag Remelting

5 VIM+PESR: Mgbaze induction oghere

| Nhọrọ ọgwụgwọ okpomọkụ: |

1 + A: Annealed (zuru / nro / spheroidizing)

2 +N: ahaziri

3 +NT: Haziri na iwe ọkụ

4 + QT: agbanyụ ọkụ na iwe ọkụ (mmiri / mmanụ)

5 +AT: ewepụla ngwọta

6 +P: Mmiri siri ike

| Ọgwụgwọ okpomọkụ: |

Ngwọta ọgwụgwọ (Ọnọdụ A) - Ọkwa 630 igwe anaghị agba nchara na-ekpo ọkụ na 1040 Celsius maka 0,5 h, wee mee ka ikuku dị jụụ ruo 30 ° C. Obere akụkụ nke akara ule ndị a nwere ike imenyụ mmanụ.

Hardening - Ọkwa 630 igwe anaghị agba nchara na-ike afọ na obere okpomọkụ iji nweta ihe a chọrọ n'ibu akụrụngwa. N'oge usoro ahụ, ngbanwe nke elu na-esote site na mbelata na 0.10% maka ọnọdụ H1150, yana 0.05% maka ọnọdụ H900.

| Ụkpụrụ maka 17-4PH igwe anaghị agba nchara |

17-4PH igwe anaghị agba nchara kwekọrọ na ụkpụrụ dị iche iche nke mba ụwa na nkọwapụta, na-ahụ maka ịdị mma na arụmọrụ a pụrụ ịdabere na ya n'ofe ụlọ ọrụ dị ka ikuku ikuku, ike, na nhazi kemịkal.

| Standard Organisation | Nkọwapụta | Nkọwa |

|---|---|---|

| ASTM | ASTM A564 / A564M | Ọkọlọtọ maka igwe na-ekpo ọkụ na-ekpo ọkụ na oyi gwụchara afọ-ike siri ike igwe anaghị agba nchara na ụdị |

| ASTM A693 | Nkọwapụta maka mmiri ozuzo-ike igwe anaghị agba nchara, mpempe akwụkwọ na warara | |

| ASTM A705 / A705M | Nkọwapụta maka mmiri ozuzo arụpụtara-ike siri ike igwe anaghị agba nchara na ikpo ọkụ na-eguzogide nchara | |

| ASME | ASME SA564 / SA693 / SA705 | Nkọwapụta koodu nrụgide arịa nha nhata |

| AMS (Aerospace) | AMS 5643 | Aerospace spec maka mmanya, waya, forgings na mgbanaka na 17-4PH ngwọta-gwọọ na agadi |

| AMS 5622 | Efere, mpempe akwụkwọ, na warara | |

| EN/DIN | EN 1.4542 / DIN X5CrNiCuNb16-4 | Nhazi European maka 17-4PH nwere ihe mejupụtara ya na akụrụngwa |

| UNS | UNS S17400 | Nhọpụta Sistemu Ọnụọgụgụ ejikọtara ọnụ |

| ISO | ISO 15156-3 | Ikike maka ojiji na akụrụngwa ebe mmanụ na gburugburu gas gbara gburugburu |

| NACE | MR0175 | Ihe achọrọ maka iguzogide mgbawa nrụgide sulfide |

| Ihe kpatara ịhọrọ anyị: |

1. Ị nwere ike nweta ihe zuru oke dịka ihe ị chọrọ na ọ dịkarịa ala ọnụahịa.

2. Anyị na-enyekwa Reworks, FOB, CFR, CIF, na ọnụ ụzọ nnyefe ọnụ ụzọ. Anyị na-atụ aro ka ịme azụmahịa maka mbupu nke ga-adị oke ọnụ ahịa.

3. Ihe anyị na-enye bụ nkwenye kpamkpam, site na akwụkwọ nyocha nke akụrụngwa ruo na nkwupụta akụkụ ikpeazụ. (Akụkọ ga-egosi na achọrọ)

4. e kwere nkwa inye nzaghachi n'ime awa 24 (na-abụkarị n'otu elekere)

5. Ị nwere ike nweta ngwaahịa ọzọ, igwe ihe nnyefe na ibelata n'ichepụta oge.

6. Anyị raara onwe anyị nye ndị ahịa anyị kpamkpam. Ọ bụrụ na ọ gaghị ekwe omume imezu ihe ndị ị chọrọ mgbe ị nyochachara nhọrọ niile, anyị agaghị eduhie gị site n'ịkwe nkwa ụgha nke ga-eme ka ndị ahịa dị mma.

| Nkwenye ịdịmma nke SAKY STEEL (gụnyere ma mbibi na nke anaghị emebi emebi) |

1. Nleba anya akụkụ

2. Mechanical nyochaa dị ka tensile, elongation na mbenata nke ebe.

3. Ultrasonic ule

4. Nyocha nyocha nke kemịkalụ

5. Nnwale ike ike

6. Nnwale nchedo pitting

7. Nnwale penetrant

8. Nnwale corrosion intergranular

9. Mmetụta mmetụta

10. Metallography nnwale nnwale

| Nkwakọ ngwaahịa |

1. Nkwakọ ngwaahịa dị ezigbo mkpa karịsịa n'ihe gbasara mbupu mba ofesi nke mbupu na-agafe na ọwa dị iche iche iji ruo ebe kachasị elu, yabụ anyị na-etinye nchegbu pụrụ iche gbasara nkwakọ ngwaahịa.

2. Saky Steel's mkpọ ngwongwo anyị n'ọtụtụ ụzọ dabere na ngwaahịa. Anyị na-akwakọ ngwaahịa anyị n'ọtụtụ ụzọ, dị ka,

A na-enye 17-4PH, 630 na X5CrNiCuNb16-4 / 1.4542 n'ụdị ogwe okirikiri, mpempe akwụkwọ, ogwe dị larịị na warara oyi na-atụ. A na-eji ihe a eme ihe n'ọtụtụ ebe na mbara igwe, mmiri, akwụkwọ, ike, n'ụsọ osimiri na ụlọ ọrụ nri maka ihe ndị na-arụ ọrụ dị arọ nke igwe, bushings, turbine blades, couplings, skru, drive shafts, nuts, metric Devices.

1. Ụlọ ọrụ Aerospace

-

Ngwa igwe turbine (mkpọmkpọ ebe, osisi, ụlọ)

-

Akụkụ ọdịda ọdịda

-

Fasteners (bolts, nuts) na structural njikọ

-

Ihe mejupụtara sistemu hydraulic

2. Ụlọ ọrụ mmanụ na gas

-

Ngwá ọrụ mgbada (mkpanaka ọkpọ, oche valve, ihe ọkpọkọ)

-

Akụkụ valvụ na-eguzogide corrosion

-

Akụkụ akụrụngwa nke mmanụ (ogwe mgbapụta, ụlọ, mgbanaka akara)

3. Ụlọ ọrụ Nhazi Chemical

-

Pumps na valves eji na gburugburu acidic

-

Ndị na-ekpo ọkụ na arịa nrụgide

-

Reactors na agitator shafts

-

Ngwa maka tankị nchekwa

4. Nhazi nri & akụrụngwa ọgwụ

-

Nri-ọkwa ebu na ụgbọala components

-

Ngwa maka sterilizer dị elu

-

Ngwa ịwa ahụ na ngwa ahụike (a chọrọ asambodo)

-

Akụkụ maka usoro njikwa nrụgide ahụike

5. Injinia mmiri na Offshore

-

Ogwe ndị na-emepụta ihe na mgbakọ na-akpali akpali

-

Ogwe mgbapụta mmiri mmiri na ihe mkpuchi

-

Fasteners na nhazi ihe njikọ n'ime ụgbọ mmiri

-

Ihe ndị na-eguzogide corrosion maka nyiwe dị n'ikpere mmiri

6. Ngwá agha nuklia na ike

-

Fasteners maka nuclear reactor owuwu

-

Ngwunye tube na-akwado maka ndị na-agbanwe ọkụ

-

Ogwe valvụ hydraulic na ahụ mgbapụta

-

Akụkụ valve okpomọkụ dị elu

7. Ụlọ ọrụ ebu na ngwá ọrụ

-

okpokolo agba ntụ ntụ

-

Ike dị elu na-akpụ ogwe na nkwado

-

Ntuziaka posts na bushings maka stamping ebu

8. General Machinery & Automation

-

Ihe ndị na-ebufe ihe dị ka ogwe ngwo, njikọ, na spindles

-

Mechanical rails na n'ọnọdu mkpara na akpaaka usoro

-

Ogwe piston hydraulic ụlọ ọrụ