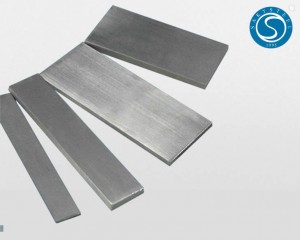

430F 430FR Ibha Yensimbi Engagqwali

Incazelo emfushane:

- Imininingwane: ASTM A838 ; EN 10088-3

- Ibanga: Ingxubevange 2, 1.4105, X6CrMoS17

- Ububanzi Bebha Eyindilinga: 1.00 mm ukuya ku-600 mm

- I-Surface Finish: Mnyama, Kuyakhanya, Kupholishiwe,

I-Saky Steel's 430FR iyinsimbi engagqwali eyi-ferritic edizayinelwe izingxenye kazibuthe ezithambile ezisebenza endaweni ebolayo. I-chromium engu-17.00% - 18.00% yenza ukumelana nokugqwala kufane no-430F. Okuqukethwe kwe-silicon okwandisiwe kule alloy kuvumela ukukhuphuka kwezici kazibuthe ngaphezu kuka-430F esimweni esihlanganisiwe. I-430FR ibonise ukusebenza okuphezulu nokungaguquguquki ngenxa yokumelana kwayo nogesi okuphezulu. Ingxubevange yenzelwe izinhlelo zokusebenza ezidinga amandla kazibuthe aphoqelelayo abuthakathaka (Hc =1.88 – 3.00 Oe [150 – 240 A/m]) njengoba kudingeka kumavalvu e-solenoid. Ukucutshungulwa kwethu okulawulwayo kuvumela izakhiwo kazibuthe ukuthi ngokuvamile zibe phezulu kunezinkambiso zemboni. I-430FR inobunzima obuningi ngaphezu kuka-430F, ngenxa yamazinga e-silicon akhuphukayo, ukunciphisa ukubola okwenzeka phakathi nemithelela ye-oscillation eyenzeka kumavalvu e-AC kanye ne-DC solenoid.

| Imininingwane yebha yensimbi engagqwali engu-430F: |

Imininingwane :I-ASTM A838 ; EN 10088-3

Ibanga:Ingxubevange 2, 1.4105, X6CrMoS17

Ubude :5.8M, 6M nobude obudingekayo

Ububanzi Bebha Eyindilinga :4.00 mm kuya ku-100 mm

Ibha Elikhanyayo :4mm - 100mm,

Isimo :Okubandayo Okudwetshiwe & Okupholishiwe Okubandayo Okudwetshiwe, Okuhlutshiwe futhi Kwakhiwe

I-Surface Finish :Mnyama, Ogqamile, Opholishiwe, Oguqukile Omabi, NO.4 Qeda, Math Qeda

Ifomu :Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged Njll.

Qeda :I-Plain End, I-Beveled End

| 430F 430FR Amabanga Alinganayo Ebha Yensimbi Engagqwali: |

| IZINGA | I-UNS | I-WERKSTOFF NR. | I-JIS | EN |

| 430F | I-S43020 | 1.4104 | I-SUS 430F | |

| 430FR | 1.4105 | I-SUS 430FR | x6CrMoS17 |

| I-430F 430FR Ibha Yekhemikhali ye-SS |

| Ibanga | C | Mn | Si | P | S | Cr | Mo | Fe |

| 430F | 0.12 ubuningi | 1.25 ubuningi | 1.0 ubuningi | 0.06 ubuningi | 0.15 imiz | 16.0-18.0 | U-Bal. | |

| 430FR | 0.065 ubuningi | 0.08 ubuningi | 1.0-1.50 | 0.03 ubuningi | 0.25-0.40 | 17.25-18.25 | 0.50 ubuningi | U-Bal. |

| Insimbi Engagqwali WERKSTOFF NR. 1.4105 Amabha Mechanical Properties |

| Ibanga | Amandla E-Tensile (MPa) min | Ubude (% ku-50mm) min | Amandla Esivuno 0.2% Ubufakazi (MPa) min | Ukuqina |

| I-Brinell (HB) ubuningi | ||||

| 430F | 552 | 25 | 379 | 262 |

| 430FR | 540 | 30 | 350 |

Phawula, uma ufuna ukwazi 430 430Se Stainless Steel Bar, Pls chofozalapha;

| Ukuhlolwa kwe-UT ye-430FR Stainless Steel Bar |

Ukuhlolwa kwe-Ultrasonic (UT) kuyindlela yokuhlola eyinhloko engabhubhisi esetshenziselwa ukuhlola ikhwalithi yangaphakathi ye-430F kanye ne-430FR yensimbi yensimbi engagqwali. Lezi zinsimbi ezingenasici ze-ferritic ezisebenza ngokukhululekile zivame ukusetshenziswa emshinini wezimoto, i-solenoid valve, kanye nezingxenye zomshini onembile lapho kokubili izici zikakazibuthe nokusebenza kwemishini kubalulekile. I-UT yenzelwe ukuthola amaphutha angaphakathi njengokuqhekeka, i-voids, noma okufakiwe okungafaka engcupheni ukusebenza komshini. Amagagasi omsindo wemvamisa ephezulu angeniswa kubha, futhi ukubonakaliswa okuvela emaphutheni kuyahlaziywa ukuze kuqinisekiswe ukuthi ibha ihlangabezana nezindinganiso ezidingekayo zobuqotho. Kuzinhlelo zokusebenza ezibucayi, i-UT iqhutshwa ngokuhambisana ne-ASTM A388 noma imininingwane efanayo ukuze kuqinisekiswe ukuzwakala kwesakhiwo nokusebenza okungaguquguquki ezindaweni ezifunayo.

|  |

| 430 Ibha Yensimbi Engagqwali Ukuhlolwa Kokuqina |

| Kungani Khetha Thina |

1. Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani inani elingenzeka.

2. Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokudiliva umnyango nomnyango. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

3. Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina.(Imibiko izovela ngokwemfuneko)

4. isiqinisekiso sokunikeza impendulo phakathi namahora angu-24(imvamisa ngehora elifanayo)

5. Ungathola ezinye izindlela zesitoko, ukulethwa komshini ngokunciphisa isikhathi sokukhiqiza.

6. Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

| Ukuqinisekisa Ikhwalithi Ye-SAKY STEEL (okuhlanganisa kokubili Okubhubhisayo Nokungabhidlizi) : |

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Ukuhlolwa kwe-Ultrasonic

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Ukuhlolwa Okungenele

8. I-Intergranular Corrosion Testing

9. Ukuhlaziywa komthelela

10. Ukuhlolwa Kokuhlola Kwe-Metallography

| Ukupakishwa: |

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,