1.4923 X22CrMoV12-1 Kaa Poe

ʻO ka wehewehe pōkole:

E ʻike i ka 1.4923 X22CrMoV12-1 kaola pōʻai kūpono no nā noi wela kiʻekiʻe e like me nā turbine a me nā paila. E ʻimi i nā waiwai, nā ana, a me nā koho hoʻoponopono.

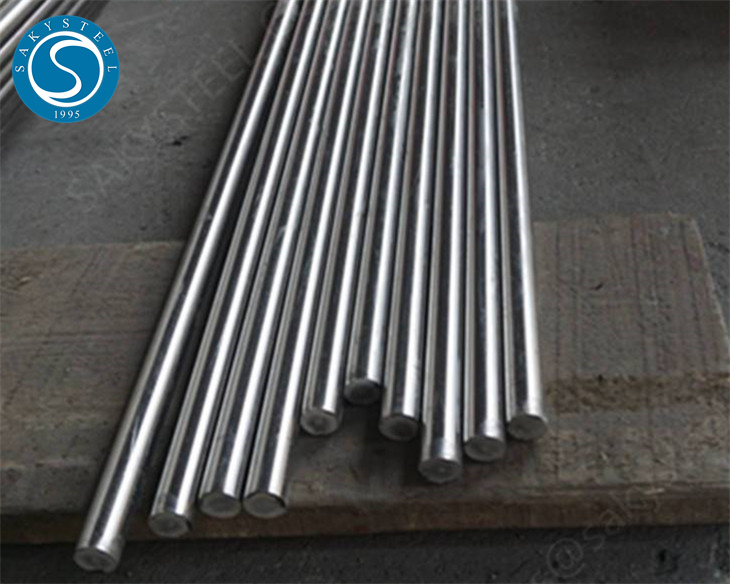

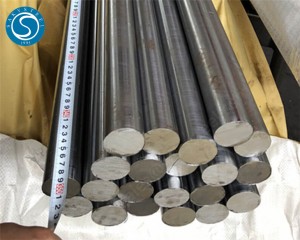

1.4923 X22CrMoV12-1 Kaa Poe:

ʻO 1.4923 (X22CrMoV12-1) nā kaola pōʻai he ikaika kiʻekiʻe, ʻaʻohe wela wela i hoʻolālā ʻia no nā noi i nā kaiapuni koʻikoʻi. Me ke kūpaʻa maikaʻi loa i nā wela kiʻekiʻe a me ka oxidation, hoʻohana maʻamau ʻia lākou i nā lau turbine, nā ʻāpana boiler, a me nā ʻōnaehana paipu kiʻekiʻe. Hāʻawi kēia mea i kahi hoʻohui kaulike o ka chromium, molybdenum, a me ka vanadium, e hōʻoiaʻiʻo ana i nā waiwai mechanical kiʻekiʻe, me ka ikaika tensile kiʻekiʻe, ka paʻakikī, a me ka lōʻihi, ʻoiai ma nā mahana kiʻekiʻe a hiki i 600 ° C. He kūpono no nā ʻoihana e koi ana i ka hilinaʻi ma lalo o ke koʻikoʻi wela, 1.4923 mau kaola pōʻai e hoʻokō i nā kūlana DIN a me EN, e hōʻoia ana i ka maikaʻi a me ka hana.

Nā kikoʻī o X22CrMoV12-1 Poʻa Poʻe:

| ʻO ke kumu hoʻāʻo kani kani ultrasonic | DIN EN 10269 |

| Papa | 1.4923, X22CrMoV12-1 |

| Ka lōʻihi | 1-12M & Koi ʻia ka lōʻihi |

| Hoʻopau ʻili | ʻEleʻele, Bright |

| Puka | Poʻapuni |

| Hoʻopau | Wela Plain, Wela Beveled |

| Palapala Hoao Mill | EN 10204 3.1 a i ʻole EN 10204 3.2 |

1.4923 Papa Poʻe Poʻe Kaulike:

| DIN | WERKSTOFF NR. | AISI |

| X22CrMoV12-1 | 1.4923 | X22 |

X22CrMoV12-1 Poepoe Bar Kemimi

| C | Mn | P | S | Si | Cr | Ni | Mo |

| 0.18-0.24 | 0.4-0.9 | 0.025 | 0.015 | 0.50 | 11.0-12.5 | 0.3-0.8 | 0.8-1.2 |

.

| Mea waiwai | Ka ikaika hua (Mpa) | Ikaika U'i (Mpa) | ʻoʻoleʻa |

| 1.4923 | 600 | 750-950 | 240-310 HBW |

Nā hiʻohiʻona o 1.4923 Steel (X22CrMoV12-1):

1.Excellent Heat kū'ē:Mālama ka 1.4923 kila i nā waiwai mechanical paʻa ma lalo o nā wela kiʻekiʻe (a hiki i 600 ° C), i mea kūpono no ka hoʻohana lōʻihi i nā wahi wela a me ke kiʻekiʻe.

2.High ikaika a me ka paakiki:Me ka ikaika tensile kiʻekiʻe (750-950 MPa) a me ka paʻakikī koʻikoʻi, e hōʻoia kēia kila i ka hana hilinaʻi ma lalo o ke koʻikoʻi wela a me ka mechanical.

3.Oxidation a me ka Corrosion Kū'ē:ʻO kona hui pū ʻana, e hōʻike ana i ka chromium kiʻekiʻe (10.5-12.5%) a me ka molybdenum (0.9-1.2%), hāʻawi maikaʻi loa i ka pale ʻana i ka oxidation a me ka corrosion i nā kūlana wela kiʻekiʻe.

4.Maikaʻi Heat Treatability:Hiki ke hoʻonui ʻia ke kila 1.4923 ma o ke kinai ʻana a me ka hoʻomaʻamaʻa ʻana, hoʻonui i kona paʻakikī, ikaika, a paʻakikī e hoʻokō i nā koi ʻenehana like ʻole.

5.Wide Industrial Applications:Hoʻohana maʻamau i nā ʻāpana i hōʻike ʻia i nā wela kiʻekiʻe a me nā puʻe, e like me: ʻO nā lau turbine steam, ʻāpana Boiler, Heat exchangers, High-pressure pipe, Compliance with International Standards.

No ke aha e koho ai iā mākou?

•Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

•Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka i ka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

•Hiki ke hōʻoia ʻia nā mea a mākou e hāʻawi ai, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope. (E hōʻike ʻia nā hōʻike ma ke koi)

•Ke hōʻoiaʻiʻo nei mākou e hāʻawi i kahi pane i loko o 24 mau hola (maʻamau i ka hola hoʻokahi)

•Hāʻawi i ka hōʻike SGS TUV.

•Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

•Hāʻawi i ka lawelawe hoʻokahi.

1.4923 Puʻupuʻu lāʻau pōʻai:

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,