1.4923 X22CrMoV12-1 Amabha Ajikelezayo

Incazelo emfushane:

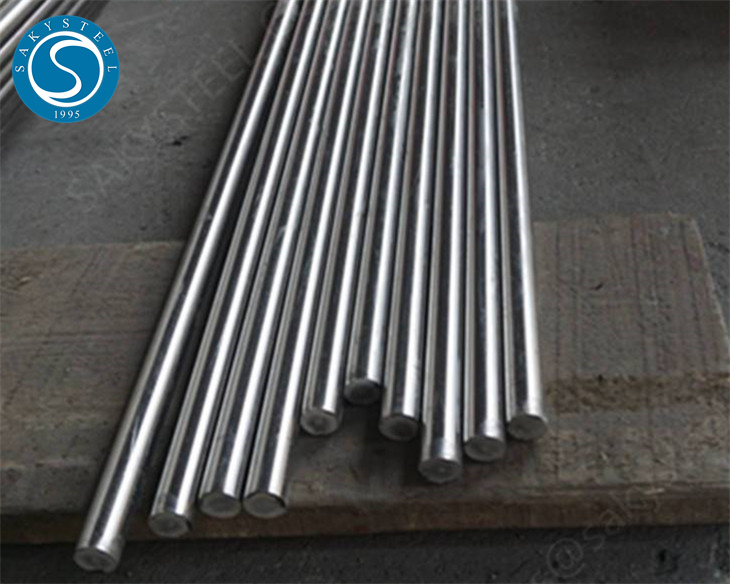

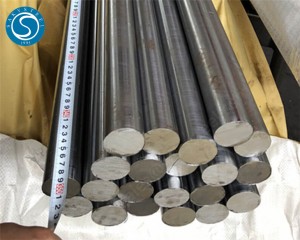

Zitholele amabha ayindilinga angu-1.4923 X22CrMoV12-1 alungele izinhlelo zokusebenza ezinezinga eliphezulu lokushisa njengama-turbine namabhayela. Hlola izakhiwo, ubukhulu, nezinketho zokwenza ngendlela oyifisayo.

1.4923 X22CrMoV12-1 Amabha Ajikelezayo:

1.4923 (X22CrMoV12-1) amabha ayindilinga angamandla aphezulu, amabha ensimbi angangeni ekushiseni adizayinelwe ukusetshenziswa ezindaweni ezidlulele. Ngokumelana okuhle kakhulu namazinga okushisa aphezulu kanye ne-oxidation, avame ukusetshenziswa kuma-turbine blades, izingxenye ze-boiler, nezinhlelo zamapayipi ezinomfutho ophezulu. Lokhu okubalulekile kunikeza ukwakheka okunokulinganisela kwe-chromium, i-molybdenum, ne-vanadium, eqinisekisa izici zomshini ezisezingeni eliphezulu, okuhlanganisa amandla aqinile, ukuqina, nokuqina, ngisho nakumazinga okushisa afinyelela ku-600°C. Ilungele izimboni ezidinga ukwethembeka ngaphansi kwengcindezi yokushisa, amabha ayindilinga angu-1.4923 ahlangabezana namazinga aqinile we-DIN kanye ne-EN, okuqinisekisa ikhwalithi engaguquki nokusebenza.

Imininingwane Yebha Eyindilinga ye-X22CrMoV12-1:

| I-Ultrasonic Test Standard | I-DIN EN 10269 |

| Ibanga | 1.4923, X22CrMoV12-1 |

| Ubude | 1-12M & Ubude obudingekayo |

| I-Surface Qeda | Emnyama, Ekhanyayo |

| Ifomu | Umjikelezo |

| Qeda | I-Plain End, I-Beveled End |

| Isitifiketi Sokuhlolwa Kwemishini | EN 10204 3.1 noma EN 10204 3.2 |

1.4923 Amabanga Alinganayo Ebha Eyindilinga:

| I-DIN | I-WERKSTOFF NR. | AISI |

| I-X22CrMoV12-1 | 1.4923 | X22 |

I-X22CrMoV12-1 Ukwakhiwa Kwekhemikhali Yebha Eyindilinga:

| C | Mn | P | S | Si | Cr | Ni | Mo |

| 0.18-0.24 | 0.4-0.9 | 0.025 | 0.015 | 0.50 | 11.0-12.5 | 0.3-0.8 | 0.8-1.2 |

1.4923 Izakhiwo ze-Steel Bars Mechanical:

| Okubalulekile | Isivuno Amandla (Mpa) | Amandla Okuqina (Mpa) | Ukuqina |

| 1.4923 | 600 | 750-950 | 240-310 HBW |

Izici ze-1.4923 Steel (X22CrMoV12-1):

1.Ukumelana Nokushisa Okuhle Kakhulu:Insimbi ye-1.4923 igcina izinto ezizinzile zemishini ngaphansi kwamazinga okushisa aphezulu (kufika ku-600 ° C), okwenza kube kuhle ukusetshenziswa kwesikhathi eside ezindaweni ezishisa kakhulu nezinomfutho ophezulu.

2.Amandla aphezulu kanye nokuqina:Ngamandla aqinile aphezulu (750-950 MPa) kanye nokuqina okungavamile, le nsimbi iqinisekisa ukusebenza okuthembekile ngaphansi kwengcindezi eshisayo neyomshini.

3.Ukumelana ne-Oxidation kanye Nokugqwala:Ukwakheka kwayo kwe-alloy, okune-chromium ephezulu (10.5-12.5%) ne-molybdenum (0.9-1.2%), kunikeza ukumelana okuhle kakhulu ne-oxidation kanye nokugqwala ezimweni zokushisa eziphakeme.

4.Ukwelashwa Okuhle Kokushisa:Insimbi engu-1.4923 ingathuthukiswa ngokucisha nokushisa, ithuthukise ubulukhuni bayo, amandla, nokuqina ukuze ihlangabezane nezidingo ezihlukahlukene zobunjiniyela.

5.Izicelo Ezibanzi Zezimboni:Okuvame ukusetshenziswa ezingxenyeni ezivezwe kumazinga okushisa aphezulu nezingcindezi, ezifana nalezi:ama-turbine blades,Izingxenye ze-Boiler,Izishintshi zokushisa,amapayipi anomfutho ophezulu,Ukuthobelana Namazinga Omhlaba.

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS TUV.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

1.4923 Ukupakishwa Kwebha Eyindilinga:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,