Stainless hlau centerless sib tsoo bar

Lus piav qhia luv luv:

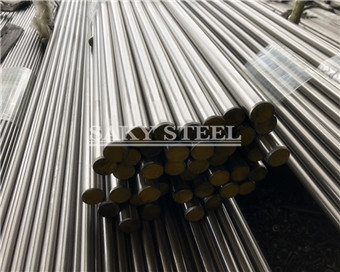

Saky Steel yog cov chaw tsim khoom ntawm Stainless hlau centerless sib tsoo bar. Peb stainless centerless sib tsoo bar tau tsim raws li tus txheej txheem thoob ntiaj teb rau kev siv machining thiab kev lag luam. Peb qhov chaw tsis muaj kev sib tsoo yog ib qho ntawm cov khoom tsim nyog tshaj plaws rau ntau yam kev siv xws li machining cov cuab yeej, fasteners, automotive daim ntaub ntawv, twj tso kua mis shafts, motor shafts, valve thiab ntau yam ntxiv.

Peb stainless hlau centerless sib tsoo bar yog ib qho ntawm feem ntau ntawm cov tuav rau ntau yam khoom tsim nyob rau hauv kev ua lag luam. Nws muaj zog corrosion kuj muaj peev xwm thiab tsis tshua muaj txij nkawm yam ntxwv uas ua rau nws yog ib yam khoom kiag li rau ntau yam kev siv.

Pebstainless hlau ci round barsmuaj ntau qib thiab sib txawv. Peb kuj muab kev pabcuam tsim khoom raws li cov neeg siv khoom xav tau.

| Stainless Hlau Round Bar Bright Khoom Qhia: |

| Stainless hlau centerless sib tsoo bar Qib: |

| Specification: | TS EN ISO 286-2 |

| Stainless hlau Round Bars: | Sab nraud txoj kab uas hla ntawm 4mm mus rau 50mm |

| Austenitic Qib (300 series) | 303, 303Cu, 303F, 304,304L, 304F, SUS316,316L, 316L, 316LF, 316LS, |

| Ferritic Qib (400 series) | 416, 416, 420, 420, 430, 430, 431, SUS420J2 |

| Lwm Qib | 1215/12L14, 1144, AW |

| Khoom Muag Khoom: | Tshuaj Annealed, Mos Annealed, Tshuaj Annealed, Quenched & Tempered, Ultrasonic Tested, Dawb los ntawm Deg Defects thiab Cracks, Dawb los ntawm cov kab mob. |

| Ntev: | 2.0 2.5 meters & raws li tus neeg yuav tsum tau muaj |

| Ua tiav: | Nruab nrab tsis muaj av |

| Ntim: | Txhua lub steel bar muaj lub singal, thiab ob peb yuav tau bundled los ntawm weaving hnab los yog raws li ib tug yuav tsum tau. |

| Specifications |

TS EN ISO 286-2 Kev ua siab ntev (chav kawm raws li kev ua tiav)

| Tiav lawmQhov xwm txheej | Cov chav kawm kam rau ua ISO 286-2 | ||||||

| h6 | h7 | h8 | h9 | h10 ua | h11 ua | h12 ua | |

| Kos | R | R | R, S, H | R, S, H | |||

| Hloov | R | R | R | R | |||

| Hauv av | R | R | R | R | R | R | R |

| Polished | R | R | R | R | R | R | R |

| R = puag ncig, S = square, H = hexagon | |||||||

| TS EN ISO 286-2 Kev Ua Haujlwm Siab: |

| NominalDimension mm | Cov chav kawm kam rau ua ISO 286-2 | ||||||

| h6 | h7 | h8 | h9 | h10 ua | h11 ua | h12 ua | |

| > 1 txog ≤ 3 | 0.006 ib | 0.010 ib | 0.014 ib | 0.025 ib | 0.040 ib | 0.060 ib | 0.100 Nws |

| > 3 rau ≤ 6 | 0.008 ib | 0.012 ib | 0.018 ib | 0.030 Nws | 0.048 ib | 0.075 ib | 0.120 Nws |

| > 6 txog ≤ 10 | 0.009 ib | 0.015 ib | 0.022 ib | 0.036 ib | 0.058 ib | 0.090 ib | 0.150 Nws |

| > 10 txog ≤ 18 | 0.011 ib | 0.018 ib | 0.027 ib | 0.043 ib | 0.070 ib | 0.110 Nws | 0.180 Nws |

| > 18 txog ≤ 30 | 0.013 ib | 0.021 ib | 0,03 3 | 0.052 ib | 0.084 ib | 0.130 Nws | 0.210 Nws |

| > 30 txog ≤ 50 | 0.016 ib | 0.025 ib | 0.039 ib | 0.062 ib | 0.100 Nws | 0.160 Nws | 0.250 Nws |

| > 50 txog ≤ 80 | 0.019 ib | 0.030 Nws | 0.046 ib | 0.074 ib | 0.120 Nws | 0.190 Nws | 0.300 Nws |

| > 80 rau ≤ 120 | 0.022 ib | 0.035 ib | 0.054 ib | 0.087 ib | 0.140 Nws | 0.220 Nws | 0.350 Nws |

| > 120 txog ≤ 180 | 0.025 ib | 0.040 ib | 0.063 ua | 0.100 Nws | 0.160 Nws | 0.250 Nws | 0.400 Nws |

| > 180 rau ≤ 200 | 0.029 ib | 0.046 ib | 0.072 ib | 0.115 ib | 0.185 ib | 0.290 Nws | 0.460 ib |

Cov kev sib txawv saum toj no yog qhov tsis zoo pov tseg txog qhov nominal dimension.

Piv txwv li 20mm nominal txoj kab uas hla muaj ib tug kam rau ua chav kawm h9 yog 20mm +0, -0.052mm los yog 19,948/20,000 mm

| Stainless hlau sib tsoo bar Ncaj soj ntsuam: |

Kev tshuaj xyuas ncaj nraim ntawm stainless hlau sib tsoo tuav yog qhov tseem ceeb ntawm kev tswj xyuas cov txheej txheem siv los xyuas kom cov tuav tau raws li qhov yuav tsum tau ua rau kev ncaj. Qhov kev tshuaj xyuas no feem ntau suav nrog ntsuas qhov sib txawv ntawm qhov bar los ntawm txoj kab ncaj nraim raws nws qhov ntev. Cov txheej txheem yuav siv cov cuab yeej tshwj xeeb xws li laser sensors, dial indicators, lossis precision ncaj npoo los ntsuas qhov ncaj ntawm qhov bar. Ib qho kev sib txawv dhau qhov kev txwv yuav cuam tshuam rau lub bar qhov kev ua tau zoo hauv kev ua haujlwm tom ntej lossis cov txheej txheem sib dhos. Qhov kev tshuaj xyuas no pab ua kom cov tuav tau zoo rau cov ntawv thov uas qhov kev sib tw thiab kev sib raug zoo yog qhov tseem ceeb, xws li hauv kev tsim cov tshuab precision lossis cov khoom siv.

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj): |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Ultrasonic kuaj

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kuaj

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev soj ntsuam cuam tshuam

10. Metallography Experimental Test

| SAKY STEEL's Core Advantages: |

1.Straightness: 400MM≤0.01;

2. Txoj kab uas hla ≤0.004;

3.Length: Raws li cov neeg siv khoom xav tau;

4.Magnetic: Tag nrho cov txheej txheem degaussing;

5.Degree ntawm tiav: Nyob ze rau Ra 0.4;

| Ntim: |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel ntim peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,