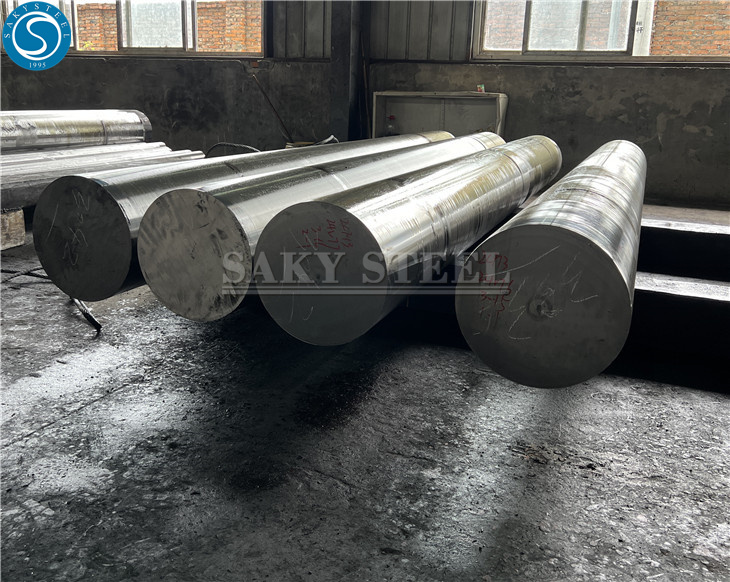

86CRMOV7 1.2327 Sesebelisoa sa tšepe

Tlhaloso e Khutšoanyane:

86CRMOV7 (1.2327) tšepe ea sesebelisoa e fana ka khanyetso e ntle ea ho roala, ho tiea ho hoholo, le botsitso ba mocheso. E loketse indasteri ea ho etsa hlobo, ea likoloi le ea lifofane.

86CRMOV7 1.2327 Tool Steel:

86CRMOV7 (1.2327) Tool Steel ke tšepe e sebetsang hantle ea alloy e tsebahalang ka ho hanyetsa ho hoholo ha eona, ho tiea ho hoholo, le botsitso ba mocheso. Ka sebopeho sa lik'hemik'hale se leka-lekaneng ka hloko, se fana ka boima bo holimo le matla, se etsa hore e be se loketseng bakeng sa lits'ebetso tse hlokang tse kang ho etsa hlobo, lisebelisoa tsa ho seha le mechini ea indasteri. Sesebelisoa sena sa tšepe se sebelisoa haholo indastering ea likoloi, sefofane, le ts'ireletso, moo ho tšoarellang le ho nepahala ho leng bohlokoa. Ts'ebetso ea eona e tsitsitseng tlas'a maemo a feteletseng e tiisa ho tšepahala le ho phela nako e telele, ho etsa hore e be khetho e khethiloeng bakeng sa tharollo ea lisebelisoa tsa boleng bo phahameng.

Litlhaloso tsa H11 1.2378 TOOL STEELS:

| Kereiti | 86CRMOV7, 1.2327 |

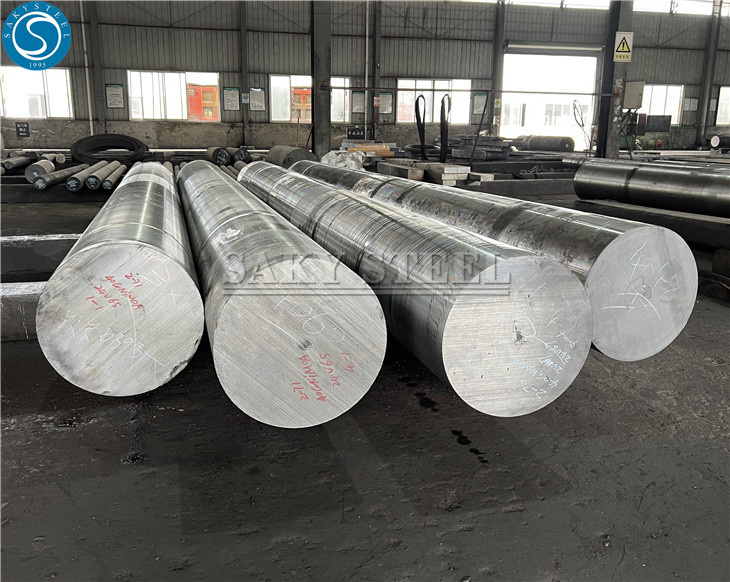

| Bokaholimo | Batsho; E peeled; E bentšitsoeng; E entsoe ka mochini; Ho sila; E retelehile; Milled |

| Ho sebetsa | Cold Drawn & polished Cold Drawn, Centreless Ground & polished |

| Setifikeiti sa Tlhahlobo ea Mill | En 10204 3.1 kapa En 10204 3.2 |

1.2327 THUL STELS e lekanang:

| DIN | AISI | JIS | ISO |

| 1.2327 | 86CrMoV7 | SKD7 | X86CrMoV7 |

1.2327 Tool Steels Sebopeho sa Lik'hemik'hale:

| C | Si | Mn | S | Cr | Mo | V | P |

| 0.83-0.90 | 0.15-0,35 | 0.30-0,45 | 0.030 | 1.6-1.9 | 0.2-0.35 | 0.05-0.15 | 0.03 |

86CRMOV7 TOOL Steels Mechanical Properties:

| Tensile Matla (MPa) | Elongation (%) | Yield Strength(MPa) | Ho thatafala (HRC) |

| 2000 | 10 | 1500 | 58-62 |

Likarolo tsa 1.2327 Tool Steel:

• Boima bo phahameng le ho hanyetsa ho roala: Ka mor'a ho tima, boima bo ka fihla ka holimo ho 60HRC, ho etsa hore e tšoanelehe bakeng sa maemo a phahameng a matla le a sa sebetseng a sebetsang.

• Ho Toughness Excellent: E boloka khanyetso e ntle ea tšusumetso le tlas'a maemo a matla a phahameng.

• Matla a Thermal Stability: E loketse ts'ebetso ea mocheso o phahameng o nang le botsitso bo botle ba dimensional.

• Tlhokahalo ea 'Maraka: Ka lebaka la ts'ebetso ea eona e hlahelletseng, 86CRMOV7 1.2327 e tumme haholo 'marakeng oa litšepe oa lisebelisoa tsa lefats'e, haholo indastering ea tlhahiso e nepahetseng le e apereng hlobo e phahameng.

Lisebelisoa tsa 1.2327 Tool Steel:

1.Automotive Manufacturing: E sebelisoa bakeng sa ho hatakela ka matla a phahameng a shoa le likarolo tsa enjene.

2.Aerospace: E hlahisa likarolo tse phahameng tsa mocheso, tse matla haholo.

3. Tlhahiso ea Sesole: E sebelisoa likarolong tsa libetsa tse nepahetseng le liforomo tsa boemo ba sesole.

4.Plastiki Molds: E loketse bakeng sa ho roala ha polasetiki e phahameng e shoa, e lelefatsa bophelo ba tšebeletso.

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

Litšebeletso tsa Rōna

1. Ho khutsisa le ho khutsisa

2.Ho phekola mocheso oa vacuum

3.Bokaholimo bo pentiloeng ka seipone

4.Precision-milled finish

4.CNC mechine

5.Ho cheka ka mokhoa o nepahetseng

6.Khaola likarolo tse nyane

7.Fihlella ho nepahala ha hlobo

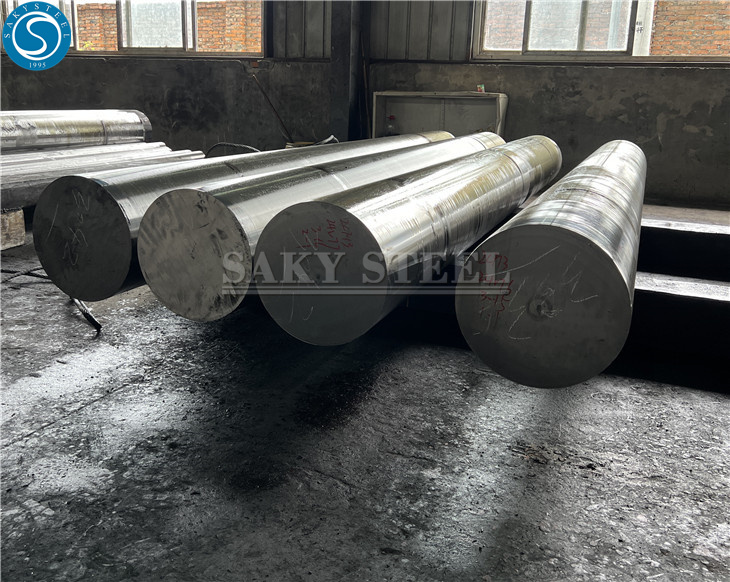

Ho paka:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,