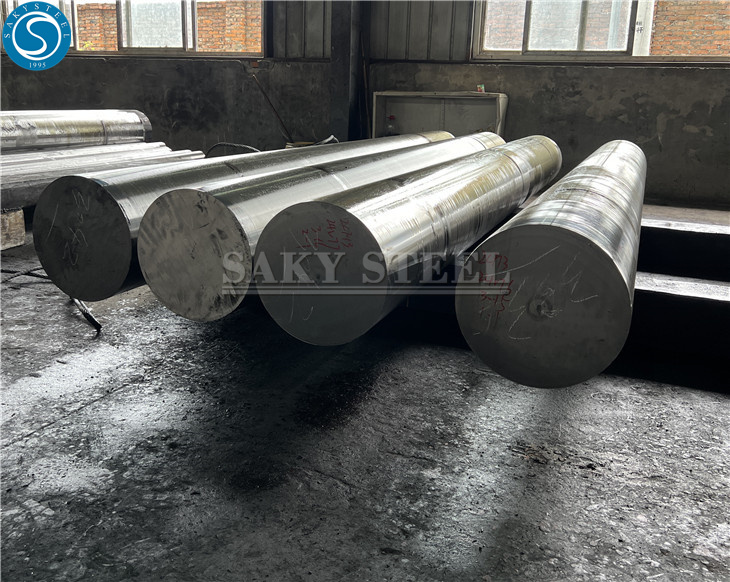

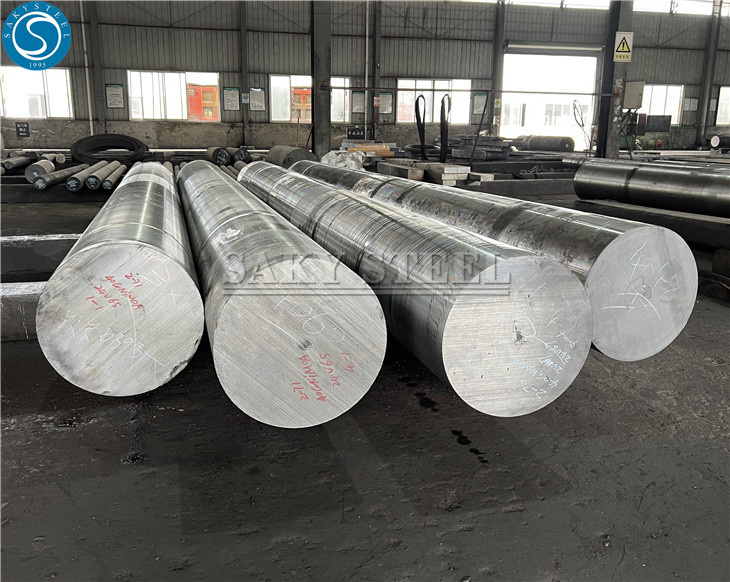

86CRMOV7 1.2327 Tool Steel

Tsanangudzo Pfupi

86CRMOV7 (1.2327) simbi yemidziyo inopa yakanakisa kupfeka kuramba, kusimba kwepamusoro, uye kugadzikana kwekupisa. Yakanakira kugadzira mold, mota, uye aerospace maindasitiri.

86CRMOV7 1.2327 Turusi Simbi:

86CRMOV7 (1.2327) Tool Steel isimbi yepamusoro-soro inozivikanwa nekunaka kwayo kupfeka kusagadzikana, kusimba kwepamusoro, uye kugadzikana kwekupisa. Nekunyatso kurongeka kwemakemikari kuumbwa, inopa kuoma kwepamusoro uye kusimba, zvichiita kuti ive yakakodzera kune inoda maapplication akadai sekugadzira mold, maturusi ekucheka, uye michina yemaindasitiri. Ichi chishandiso simbi chinoshandiswa zvakanyanya mumotokari, aerospace, uye maindasitiri ekudzivirira, uko kusimba uye nemazvo kwakakosha. Kuita kwayo kusingachinji pasi pemamiriro akanyanya kunovimbisa kuvimbika uye hupenyu hurefu, zvichiita kuti ive sarudzo inosarudzika yemhando yepamusoro yezvigadziriso zvekushandisa.

Zvinotsanangurwa zveH11 1.2378 TOOL STEELS:

| Giredhi | 86CRMOV7, 1.2327 |

| Surface | Nhema; Peeled; Polished; Machined; Grinded; Turned; Milled |

| Processing | Cold Drawn & polished Cold Drawn, Centreless Ground & Polished |

| Mill Test Certificate | En 10204 3.1 kana En 10204 3.2 |

1.2327 TOOL STEELS zvakaenzana:

| DIN | AISI | JIS | ISO |

| 1.2327 | 86CrMoV7 | SKD7 | X86CrMoV7 |

1.2327 TOOL STEELS Chemical Maumbirwo:

| C | Si | Mn | S | Cr | Mo | V | P |

| 0.83-0.90 | 0.15-0.35 | 0.30-0.45 | 0.030 | 1.6-1.9 | 0.2-0.35 | 0.05-0.15 | 0.03 |

86CRMOV7 TOOL STEELS Mechanical Properties:

| Tensile simba (MPa) | Elongation (%) | Goho Simba (MPa) | Kuoma (HRC) |

| 2000 | 10 | 1500 | 58-62 |

Zvimiro zve1.2327 Tool Steel:

• High Hardness uye Wear Resistance: Mushure mokudzima, kuoma kunogona kusvika pamusoro pe60HRC, zvichiita kuti zvive zvakakodzera kune yakakwirira-simba uye kupfeka-kusagadzikana kwekushanda.

• Excellent Toughness: Inochengetedza maitiro akanaka ekupikisa kunyange pasi pemamiriro epamusoro-simba.

• Kusimba Kwakasimba Kwekupisa: Inokodzera kushanda kwepamusoro-tembiricha ine yakanakisa dimensional kugadzikana.

• Kudiwa Kwemusika: Nekuda kwekuita kwayo kwakatanhamara, 86CRMOV7 1.2327 inofarirwa zvakanyanya mumusika wepasi rose wesimbi simbi, kunyanya mukugadzira kwakanyatso kugadzirwa uye yakakwirira-kupfeka mold maindasitiri.

Zvishandiso zve1.2327 Tool Steel:

1.Automotive Manufacturing: Inoshandiswa kune yakakwirira-simba stamping inofa uye injini zvikamu.

2.Aerospace: Inogadzira yakakwirira-kupisa, yakakwirira-yakasimba structural components.

3.Mauto Manufacturing: Inoshandiswa muzvikamu zvezvombo zvakarurama uye zviumbwa zvehondo.

4.Plastic Molds: Inokodzera kuumbwa kwepurasitiki yepamusoro inofa, kuwedzera hupenyu hwebasa.

Sei Sarudza isu?

•Iwe unogona kuwana iyo yakakwana zvinhu zvinoenderana nezvinodiwa zvako pamutengo unogoneka.

•Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekuendesa gonhi kumusuwo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

•Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pachitupa chebvunzo kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

•Isu tinovimbisa kupa mhinduro mukati me24hours (kazhinji muawa imwe chete)

•Ipa SGS TUV chirevo.

•Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

•Ipa imwe-stop service.

Masevhisi Edu

1.Kudzima uye kupisa

2.Vacuum kupisa kurapa

3.Mirror-polished surface

4.Precision-milled finish

4.CNC machining

5.Precision drilling

6.Cheka muzvikamu zviduku

7.Achieve mold-kufanana nemazvo

Packing:

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,