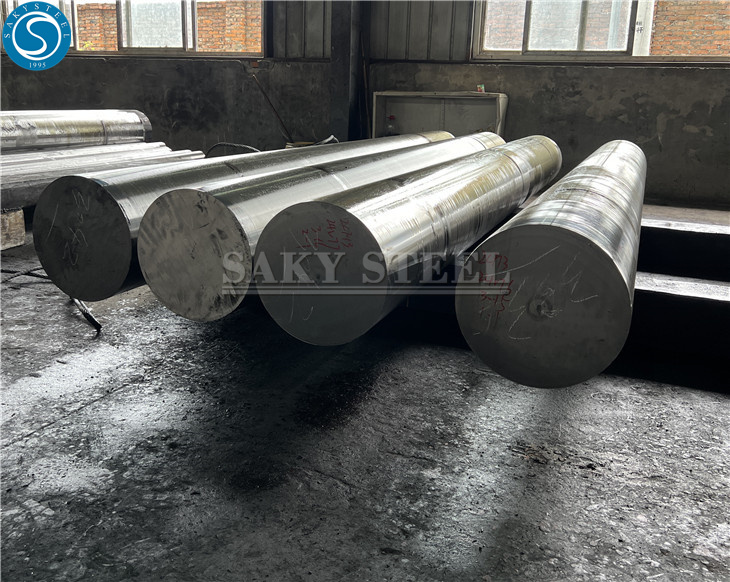

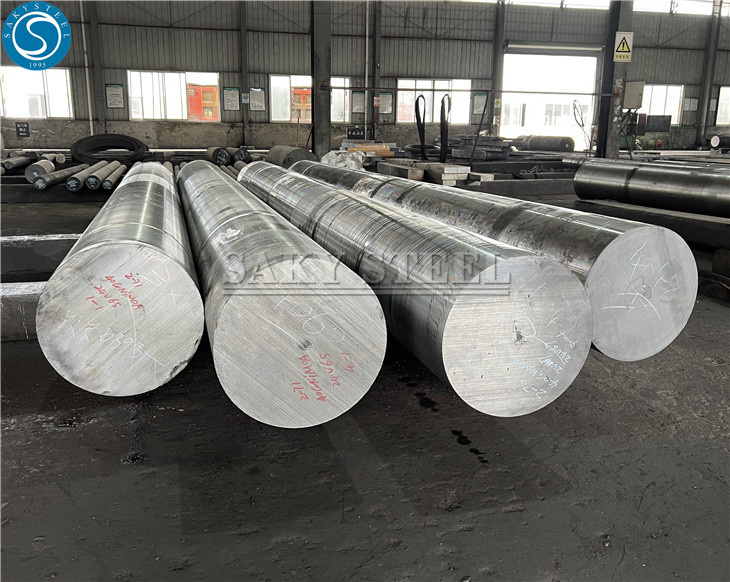

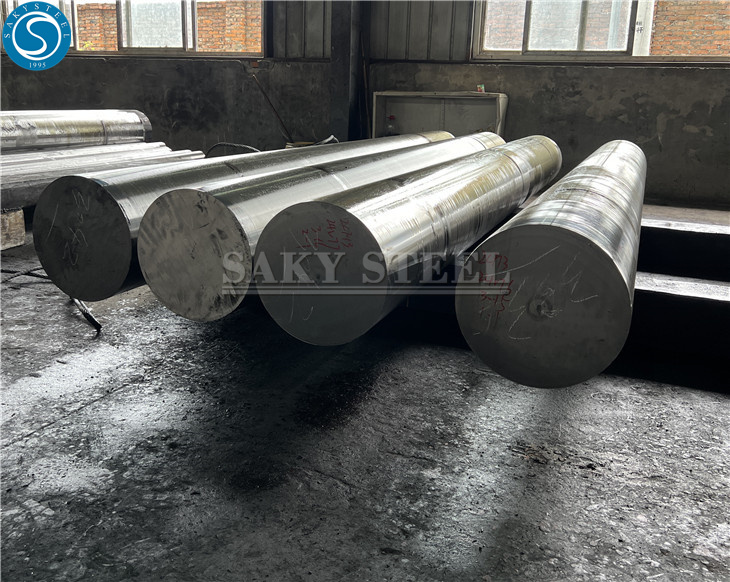

86CRMOV7 1.2327 Insimbi Yamathuluzi

Incazelo emfushane:

I-86CRMOV7 (1.2327) insimbi yamathuluzi inikeza ukumelana okuhle nokugqokwa, ukuqina okuphezulu, nokuzinza kwe-thermal. Ilungele ukwenza isikhunta, izimboni zezimoto, kanye ne-aerospace.

86CRMOV7 1.2327 Insimbi Yethuluzi:

I-86CRMOV7 (1.2327) I-Tool Steel iyinsimbi ye-alloy esebenza kahle kakhulu eyaziwa ngokumelana kwayo nokugqokwa okuhle kakhulu, ukuqina okuphezulu, nokuzinza kwe-thermal. Ngokwakheka kwamakhemikhali okulinganiselwe ngokucophelela, inikeza ukuqina namandla aphakeme, okuyenza ifanelekele izinhlelo zokusebenza ezinzima ezifana nokwenza isikhunta, amathuluzi okusika, nemishini yezimboni. Leli thuluzi lensimbi lisetshenziswa kakhulu ezimbonini zezimoto, ze-aerospace, nezokuvikela, lapho ukuqina nokunemba kubalulekile. Ukusebenza kwayo okungaguquki ngaphansi kwezimo ezimbi kakhulu kuqinisekisa ukwethembeka nokuphila isikhathi eside, okwenza kube ukukhetha okuncanyelwayo kwezixazululo zamathuluzi ezisezingeni eliphezulu.

Imininingwane Yezinsimbi Ze-H11 1.2378:

| Ibanga | 86CRMOV7, 1.2327 |

| Ubuso | Mnyama; Ihlutshiwe; Ipholishiwe; Okwenziwe ngomshini; Kugaywe; Iphendukile; Igayiwe |

| Iyacubungula | Ebandayo Edwetshiwe & Epholishiwe Ebandayo Edwetshiwe, I-Centerless Ground & Epholishiwe |

| Isitifiketi Sokuhlolwa Kwemishini | En 10204 3.1 noma En 10204 3.2 |

1.2327 IZITEMBA ZAmathuluzi okulingana:

| I-DIN | AISI | I-JIS | ISO |

| 1.2327 | 86CrMoV7 | SKD7 | I-X86CrMoV7 |

1.2327 Tool Steels Ukwakhiwa Kwekhemikhali:

| C | Si | Mn | S | Cr | Mo | V | P |

| 0.83-0.90 | 0.15-0.35 | 0.30-0.45 | 0.030 | 1.6-1.9 | 0.2-0.35 | 0.05-0.15 | 0.03 |

86CRMOV7 Tool Steel Mechanical Properties:

| Amandla e-Tensile (MPa) | Ubude (%) | Isivuno Amandla(MPa) | Ukuqina (HRC) |

| 2000 | 10 | 1500 | 58-62 |

Izici ze-1.2327 Tool Steel:

• Ukuqina Okuphezulu Nokumelana Nokugqoka: Ngemva kokucisha, ubulukhuni bungafinyelela ngaphezu kuka-60HRC, buyenze ifanelekele izimo zokusebenza ezinamandla nezingagugi.

• Ukuqina Okuhle Kakhulu: Igcina ukumelana nomthelela omuhle ngisho nangaphansi kwezimo zamandla aphezulu.

• Ukuzinza Kwe-Thermal Okuqinile: Ifanele ukusebenza kwezinga lokushisa eliphezulu ngokuzinza kwe-dimensional okuhle kakhulu.

• Isidingo Semakethe: Ngenxa yokusebenza kwayo okuvelele, i-86CRMOV7 1.2327 idume kakhulu emakethe yensimbi yamathuluzi yomhlaba wonke, ikakhulukazi ezimbonini zokukhiqiza ezinembayo nezigqokwa kakhulu.

Ukusetshenziswa kwe-1.2327 Tool Steel:

1.Ukukhiqiza Kwezimoto: Kusetshenziselwa ukugxiviza okunamandla aphezulu kanye nezingxenye zenjini.

2.I-Aerospace: Ikhiqiza izinga lokushisa eliphezulu, izingxenye zesakhiwo ezinamandla kakhulu.

3.Ukukhiqiza Kwezempi: Kusetshenziswa ezingxenyeni zezikhali ezinembayo kanye nesikhunta sezinga lezempi.

4.Izikhunta zePlastiki: Ifanele ukubunjwa kwepulasitiki egqoke kakhulu iyafa, inweba impilo yesevisi.

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS TUV.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

Izinkonzo Zethu

1.Ukucisha nokuthulisa

2.Vacuum ukwelapha ukushisa

3.Indawo epholishwe ngesibuko

4.Ukuqeda okugayiwe ngokunembe

4.CNC imishini

5.Ukubhola okunembayo

6.Sika ube yiziqephu ezincane

7.Finyelela ukunemba okufana nesikhunta

Ukupakisha:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,