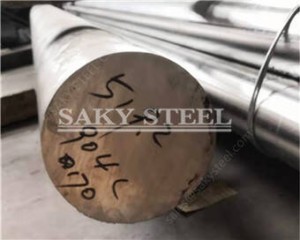

904L Stainless Steel Bar | ASTM B649 UNS N08904 Libara tse Rtoang

Tlhaloso e Khutšoanyane:

Reka tšepe ea tšepe ea 904L e sebopeho se chitja ho latela ASTM B649 UNS N08904. E thibela ho bola, k'habone e tlase, e loketse ts'ebeliso ea lik'hemik'hale le ea leoatleng. Phepelo ea lefats'e ho tsoa ho SAKYSTEEL.

904L Stainless Steel Bar:

86CRMOV7 (1.2327) Tool Steel ke tšepe e sebetsang hantle ea alloy e tsebahalang ka ho hanyetsa ho hoholo ha eona, ho tiea ho hoholo, le botsitso ba mocheso. Ka sebopeho sa lik'hemik'hale se leka-lekaneng ka hloko, se fana ka boima bo holimo le matla, se etsa hore e be se loketseng bakeng sa lits'ebetso tse hlokang tse kang ho etsa hlobo, lisebelisoa tsa ho seha le mechini ea indasteri. Sesebelisoa sena sa tšepe se sebelisoa haholo indastering ea likoloi, sefofane, le ts'ireletso, moo ho tšoarellang le ho nepahala ho leng bohlokoa. Ts'ebetso ea eona e tsitsitseng tlas'a maemo a feteletseng e tiisa ho tšepahala le ho phela nako e telele, ho etsa hore e be khetho e khethiloeng bakeng sa tharollo ea lisebelisoa tsa boleng bo phahameng.

Litlhaloso tsa SS 904L Bar:

| 904L SS Round bar boholo | Boima: 3-800mm |

|---|---|

| Alloy 904L Hex Bar boholo | 2-100mm A/F |

| 904L Steel Flat bar boholo | Botenya: 2-100mm |

| Bophara: 10 ho 500mm | |

| ASTM A276 UNS N08904 Square bar boholo | 4 ho isa ho 100 mm |

| 904L Grade Stainless Steel Angle bar size (ka mm) | 3*20*20~12*100*100 |

| Karolo ea 904L ea tšepe e sa hloekang | 3.0 ho 12.0mm botenya |

| N08904 Stainless Steel Channel Bar (ka limilimithara) | 80 x 40 ho isa ho 150 x 75 karolo; 5.0 ho isa ho 6.0 botenya |

| Stainless Steel 1.4539 Hollow Bar (ka mm) | 32 OD x 16 ID ho isa ho 250 OD x 200 ID) |

| SS 904L Billet Boholo | 1/2" ho isa ho 495mm bophara |

| Stainless Steel 904L Rectangles Size | 33 x 30mm ho isa ho 295 x 1066mm |

| Alloy 904L Round Bar Qetella | E batang (e khanyang) e huloang, mobu o se nang bohareng, o chesehang, o phethiloe hantle, o ebotsoe, o petsotsoe, o kolobisitsoeng o chesang, o phethiloe, o khanyang, oa Poland, o sila, Centreless Ground & Black. |

| 904L Steel Round Bar Surface | E khanyang, e Chesang e Pickled, e Cold Drawn, Lehlabathe le Qetetsoe, Le bentšitsoe, Mohala oa Moriri |

| 904L Stainless Steel Round Bar Condition | E thata ebile e halefile, e halefile |

| Sebaka sa rona sa 904L Steel Round bar se lumellana le NACE MR0175/ISO 15156 | |

Litlhaloso tsa Tekheniki ea Bar 904L :

| TS'ELISO | WERKSTOFF NR. | UNS | JIS | BS | KS | HLOMPHO | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Fe |

| 0.02 | 1.0 | 2.0 | 0.045 | 0.035 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | 1.0-2.0 | Ho leka-lekanya |

| Botenya | Melting Point | Matla a tšepe | Matla a Hlahisa (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi - 71000 , MPa - 490 | Psi - 32000 , MPa - 220 | 35 % |

Lethathamo la Mefuta ea 904L Stainless Steel Round Bar

| 904L Round Bar ea tšepe e se nang tšepe | ASTM A276 UNS N08904 Flat Bar |

| 904L SS Bar | 904L Steel Flat Bar Black |

| Alloy 904L Lipotoloho | 904L Grade Stainless Steel Flat Bar E Khanyang |

| 904L Steel Bright Bar | 904L Stainless Steel Flat Bar e Bentshitsoeng |

| Lithupa tsa ASTM A276 UNS N08904 | 904L SS Flat Bar Cold Drawn |

| Alloy 904L Square Bar Cold Drawn | 904L SS Bright Bar lintho tse bonahalang |

| 904L Sehlopha sa tšepe e sa hloekang ea tšepe | Stainless Steel 904L Flat Bar Annealed |

| 904L Stainless Steel Round Bars | 904L SS Flat Bar setoko |

| N08904 Stainless Steel Hex Bar | Alloy 904L Threaded Bar |

| 904L SS Square Bar e bentšitsoe | Stainless Steel 904L Bright Bar Hot Rolled |

| SS 904L Hex Bar E Khanyang | ASTM A276 UNS N08904 Hollow Bar |

| Stainless Steel 1.4539 Rectangular Bar Annealed | 904L tšepe e bentšitsoeng ea Hex Bar |

| 904L Hex Bar e hloekisitsoeng | 904L Grade Stainless Steel Hexagonal Bar |

| SS 904L Rectangular Bar | N08904 Stainless Steel Threaded Bar Black |

| 904L Steel Hex Bar e Kenyelitsoeng | N08904 Stainless Steel Cold Drawn Round Bar |

| 904L Grade Stainless Steel Forged Bar | Stainless Steel 1.4539 Bar e hloekisitsoeng |

Tlhahlobo ea 904L Bar UT

Ultrasonic Testing (UT) ke mokhoa o matla oa tlhahlobo o sa senyeheng o etsoang hoLitšepe tsa tšepe tse 904Lho lemoha mefokolo ea ka hare joalo ka mapetsong, li-voids, le li-inclusions. U sebelisa maqhubu a molumo o phahameng haholo, tlhahlobo ea UT e netefatsa boits'epo ba sebopeho sa bar le ho netefatsa ho latela maemo a thata a boleng. TsohleLi-bar tsa SAKYSTEEL 904Letsa tlhahlobo ea ultrasonic ea 100% ho latela ASTM A388 kapa litekanyetso tse lekanang, ho fa bareki tiisetso e phahameng ea ts'epo bakeng sa lits'ebetso tsa likepe tsa khatello, ts'ebetso ea lik'hemik'hale le tikoloho ea leoatle. Liphetho tsa liteko tsa UT lia fumaneha ha li kōptjoa 'me li kenyelelitsoe Setifikeiting sa Teko sa Mill (MTC) bakeng sa ho latelloa.

904L Bright bar Teko ea Concentricity

Teko ea Concentricityke mokhoa o nepahetseng oa ho hlahloba o sebelisetsoang ho netefatsa teka-tekano pakeng tsa bokaholimo ba bokantle le bo ka hare ba karolo e chitja, joalo ka phala, tube kapa bar. HoLitšepe tsa tšepe tse 904Lkapa likarolo tse entsoeng ka mokhoa o nepahetseng, ho boloka concentricity e tiileng ke ea bohlokoa ho etsa bonnete ba hore botenya ba lerako le lekanang, ho leka-lekana ha mochine, le botšepehi bo sebetsang hantle nakong ea mochine kapa ho potoloha. Teko ena hangata e etsoa ho sebelisoa matšoao a ho daela, lisebelisoa tsa ho tsamaisana le laser, kapa mochini o lekanyang o hokahanyang (CMM) ho lekanya ho kheloha lipakeng tsa mehala e bohareng. HoSAKYSTEEL, likarolo tsohle tsa bohlokoa li ka hlahlojoa bakeng sa ho tsepamisa maikutlo ha ho kōptjoa ho finyella litekanyetso tse phahameng tsa ts'ebeliso ea lisebelisoa tsa lifofane, tsa bongaka le tsa boenjiniere.

AISI 904L molamu Koba Teko

Theteko ea kobehake mokhoa oa ho hlahloba ka mochini o sebelisetsoang ho lekola hore na ho na le ductility, matla, le ho utloahala ha lisebelisoa tsa tšepe tse kang litšepe tse sa hloekang, lipoleiti kapa manonyeletso a cheselitsoeng. Nakong ea tlhahlobo, mohlala o kobeha ka lehlakoreng le itseng kapa radius ho hlahloba hore na ha ho na mapetsong a holim'a metsi, ho robeha kapa matšoao a mang a ho hlōleha. Bakeng sa lisebelisoa tse kang904L tšepe e sa hloekang, teko ea bend e thusa ho netefatsa hore sehlahisoa se ka mamella deformation ntle le ho lahleheloa ke botšepehi ba sebopeho. HoSAKYSTEEL, tlhahlobo ea bend e etsoa ho latela litekanyetso tsa ASTM kapa EN, 'me liphetho li kenyelelitsoe tlalehong ea tlhahlobo ea boleng ha u kopa, ho netefatsa hore lihlahisoa tsa rona li finyella litlhoko tse phahameng ka ho fetisisa tsa ts'ebetso le polokeho.

UNS N08904 Bar Applications

Litšepe tsa tšepe tsa 904L li atisa ho sebelisoa libakeng tse boima tsa meralo le tse thibelang ho bola ka lebaka la matla a tsona a phahameng, ho cheseha ho hoholo, le ho hanyetsa ho phahameng ho acid le chloride. Lisebelisoa tse tloaelehileng li kenyelletsa:

1. Lisebelisoa tsa lik'hemik'hale le tsa Petrochemical

• Li-shafts le lihokelo tsa litanka tsa polokelo ea asiti

• Li-pump shafts le likarolo tsa agitator tse sebelisoang tlhahiso ea sulfuric / phosphoric acid

• Likarolo tse tsamaisang khatello ka har'a li-reactor le likholomong tsa distillation

2. Mehaho ea Marine & Offshore

• Metsu e meholo ea lipompo tsa metsi a leoatle

• Li-propeller hubs le li-shafts tsa likepe tsa metsing

• Litšehetso tsa meralo bakeng sa liforomo tsa maoatle le meaho e ka tlas'a metsi

3. Indasteri ea Pulp & Paper

• Tobetsa lirolo le li-pulp agitator shafts tikolohong e nang le asiti e soeufalitsoeng

• Lithupa tsa ts'ehetso bakeng sa litanka tsa polokelo tse nang le asiti

4. Litsamaiso tsa Taolo ea Tšilafalo

• Basebeletsi ba tora ea scrubber ba tsamaiso ea flue gas desulfurization (FGD).

• Li-shafts le li-spacers bakeng sa likarolo tsa tlhahiso ea chlorine dioxide

5. Lisebelisoa tsa Oli le Khase

• Likarolo tsa khatello tse entsoeng ka har'a lithulusi tse theolelang

• Likutu tsa li-valve le li-actuator likarolong tse hloekisang khase e senyang

• Lihokelo tse ka tlas'a leoatle li pepesehetse corrosion ea chloride stress

6. Pharmaceutical & Food Processing

• Li-mixer shafts tse nang le bophara bo boholo le lithapo tsa tšehetso

• Likarolo tse thibelang ho bola litsamaisong tsa ho hloekisa sebakeng (CIP).

• Lisebelisoa tse entsoeng ka mechine lijaneng tse nang le acid-sensitive reaction

7. Likarolo tsa Mechini le Sebopeho

• Li-flanges tse entsoeng ka mochini, lihlahla le li-spacers

• Li-rods tsa sebopeho tse boima haholo sebakeng se nang le letsoai le lengata kapa se nang le asiti

• Ho etsa lintho tse tala bakeng sa likarolo tse thata tse sa jeng

Lithuto tsa Bareki

Re atlehile ho sebeletsa bareki liindastering tse latelang:

• Moetsi oa thepa ea desalination naheng ea Netherlands - liphaephe tse cheselitsoeng tsa 904L le li-flanges

• Khampani ea petrochemical Saudi Arabia - 904L lipoleiti tse boima bakeng sa linings tsa reactor

• Moetsi oa lisebelisoa tsa meriana Indonesia - li-tubes tse bentšitsoeng tsa 904L bakeng sa liphaephe tse hloekileng

Lintlha tsa bohlokoa tsa 904L Stainless Steel

Ho hanyetsa acid e ikhethang:Haholo-holo e hanyetsanang le sulfuric, phosphoric, le organic acid

E ntle ka ho fetesisa le ho hanyetsa ho bola ha crevice:E loketse tikoloho e nang le chloride e ngata

Weldability e ntle:Ho senyeha ho fokolang ha ho hanyetsa kutu libakeng tse cheselitsoeng

Likahare tsa khabone e tlase:E fokotsa kotsi ea ho bola ha intergranular

Boleng bo phahameng ba ho qetela:E loketse lisebelisoa tse hlokang libaka tse hloekileng le tse boreleli

Sebopeho se tsitsitseng sa austenitic:E hanela phetoho ea mokhahlelo leha e le mocheso o tlase

Lipotso tse atisang ho botsoa (FAQ)

Q1: Na 904L e tšoana le Inkoloy 825?

A: Li ka bapisoa le sulfuric acid resistance, empa Inkoloy 825 ke motsoako oa nickel o nang le litšenyehelo tse phahameng. 904L ke mokhoa o mong oa moruo.

Q2: Na 904L e ka chesetsoa?

A: E, e ka cheseha ka botlalo ka ho sebelisa terata e tšoanang ea filler joalo ka ER385 (904L).

Q3: Na 904L e loketse lits'ebetso tsa mocheso o tlase?

A: E, sebopeho sa eona se tsitsitseng sa austenitic se boloka ts'ebetso ka mocheso o tlase.

Mekhoa ea ho Leka

• Ho senya

• Lik'hemik'hale

• Tlhahlobo ea Pono

• Tlhahlobo ea Motho oa Boraro

• Ho phatloha

• Ha e Senye

• Mechini

• NABL Lab e amohetsoe

• PMI

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

Litšebeletso tsa Rōna

1. Ho khutsisa le ho khutsisa

2.Ho phekola mocheso oa vacuum

3.Bokaholimo bo pentiloeng ka seipone

4.Precision-milled finish

4.CNC mechine

5.Ho cheka ka mokhoa o nepahetseng

6.Khaola likarolo tse nyane

7.Fihlella ho nepahala ha hlobo

Packaging ea tšepe e sa hloekang:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,