304 316 phala ea tšepe e sa hloekang

Tlhaloso e Khutšoanyane:

| Litlhaloso tsaphala ea tšepe e sa hloekang:: |

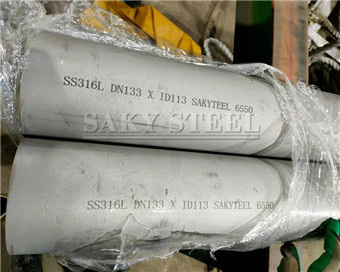

Liphaephe tse Seamless & Boholo ba Liphaephe :1 / 8″ NB – 12″ NB

Litlhaloso :ASTM A/ASME SA213, A249, A269, A312, A358, A790

E tloaelehileng :ASTM, ASME

Kereiti:304,310, 310S, 314, 316,316L, 321,347, 904L, 2205, 2507

Mekhoa:Ho chesa, ho huloa ka serame

Bolelele :5.8M, 6M,12M & Bolelele bo Hlokehang

Kantle Diameter :6.00 limilimithara OD ho fihla ho 914.4 limilimithara OD

Botenya :0.6 limilimithara ho 12.7 limilimithara

Kemiso :SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS

Mefuta :Liphaephe tse Seamless

Foromo :Round, Square, Rectangle, Hydraulic, Honed Tubes

QETA :Qetello e Sephara, Qetello e Beveled, e hatakeloa

| Stainless Steel 316 /316L Liphaephe tse Seamless Mephato e Tšoanang: |

| TS'ELISO | WERKSTOFF NR. | UNS | JIS | BS | HLOMPHO | EN |

| SS304 | 1.4301 | S30400 | SUS 304 | 304S1 | 58E | |

| SS316 | 1.4401 | S31600 | SUS 316 | 304S11 | - | 58E |

| SS 304 / 316L Liphaephe tse se nang Seam Sebopeho sa Lik'hemik'hale le thepa ea Mochini: |

| Kereiti | C | Mn | Si | P | S | Cr | Mo | Ni |

| S30400 | 0.08 max | 2.0 max | 1.00 max | 0.045 boholo | 0.030 boholo | 18.00 - 20.00 | 8.00 - 11.00 | |

| S31600 | 0.035 boholo | 2.0 max | 1.00 max | 0.045 boholo | 0.030 boholo | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 |

| Kereiti | Melting Point | Matla a tšepe | Matla a Hlahisa (0.2%Offset) |

| 304 | 1040 °C (1900 °F) | MPa - 515 | MPa - 205 |

| 316 | 1100-1170 °C (2010-2140 °F) | MPa - 515 | MPa - 205 |

| Ke Hobane'ng ha U Re Khetha |

1. U ka fumana boitsebiso bo phethahetseng ho ea ka tlhokahalo ea hau bonyane theko e ka khonehang.

2. Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

3. Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela.(Litlaleho li tla hlaha ho latela tlhoko)

4. e tiisetso ea ho fana ka karabo nakong ea lihora tse 24(hangata ka hora e tšoanang)

5. U ka fumana mefuta e meng ea li-stock, ho tsamaisoa ha leloala ka ho fokotsa nako ea tlhahiso.

6. Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

| Tiisetso ea Boleng (ho kenyeletsoa tse senyang le tse sa senyeheng) : |

1. Teko ea Visual Dimension

2. Tlhahlobo ea mochine joalo ka tensile, Elongation le phokotso ea sebaka.

3. Teko e kholo

4. Tlhahlobo ea tlhahlobo ea lik'hemik'hale

5. Teko ea boima

6. Teko ea tšireletso ea likoti

7. Flaring Testing

8. Teko ea Jet ea Metsi

9. Penetrant Test

10. Tlhahlobo ea X-ray

11. Intergranular Corrosion Testing

12. Tlhahlobo ea phello

13. Eddy tlhahlobo ea hona joale

14. Tlhahlobo ea Hydrostatic

15. Metallography Teko ea Teko

| Sephutheloana: |

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,

E phuthetsoe

Mabokose a mabokose

Liphalete tsa lehong

Mabokose a lehong

Likerese tsa lehong

| Lisebelisoa: |

1. Lik'hamphani tsa Pampiri le Pulp

2. Likopo tsa Khatello e Phahameng

3. Indasteri ea Oli le Khase

4. Ho Hloekisa Lik'hemik'hale

5. Pipeline

6. Kopo ea Mocheso o Phahameng

7. Leseli la Pipe ea Metsi

8. Limela tsa Matla a Nyutlelie

9. Liindasteri tsa ho lokisa lijo le tsa lebese

10. Boiler & Heat Exchangers

| Lintlha tse ling: |

| SN | (GB) | (DIN) | (JIS) | AISI/ASTM | UNS | SAE | (ISO) |

| 1 | 1Cr17Mn6Ni5N | SUS201 | 201 | S20100 | 30201 | A-2 | |

| 2 | 1Cr18Mn8Ni5N | X8CrMnNi189 | SUS202 | 202 | S20200 | 30202 | A-3 |

| 3 | 1Cr18Mn10Ni5Mo3N | ||||||

| 4 | 2Cr13Mn9Ni4 | ||||||

| 5 | 1Cr17Ni7 | X12CrNi17.7 | SUS301 | 301 | S30100 | 30301 | 14 |

| 6 | 1Cr17Ni8 | X12CrNi17.7 | SUS301J1 | ||||

| 7 | 1Cr18Ni9 | X12CrNi18.8 | SUS302 | 302 | S30200 | 30302 | 12 |

| 8 | Y1Cr18Ni9 | X12CrNiSi18.8 | SUS303 | 303 | S30300 | 30303 | 17 |

| 9 | Y1Cr18Ni9Se | SUS303Se | 303Se | S30323 | 30303Se | 17 | |

| 10 | 1Cr18Ni9Si3 | X12CrNiSi18.8 | SUS302B | 302B | S30215 | 30302B | |

| 11 | 0Cr18Ni9 | X5CrNi18.9 | SUS304 | 304 | S30400 | 30304 | 11 |

| 12 | 00Cr18Ni10 | X2CrNi18.9 | SUS304L | 304L | S30403 | 30304L | 10 |

| 13 | 0Cr19Ni9N | Tlhaloso: SUS404N1 | 304N | S30451 | |||

| 14 | 0Cr19Ni10NbN | X5CrNiNb18.9 | SUS304N2 | XM21 | S30452 | ||

| 15 | 00Cr18Ni10N | X2CrNiN18.10 | Tlhaloso: SUS304LN | 304LN | S30453 | ||

| 16 | 1Cr18Ni12 | X5CrNi19.11 | SUS305 | 305 | S30500 | 30305 | 13 |

| 17 | 0Cr18Ni12 | X5CrNi19.11 | |||||

| 18 | 0Cr23Ni13 | X7CrNi23.14 | SUS309S | ||||

| 19 | 0Cr25Ni20 | SUS310S | |||||

| 20 | 0Cr17Ni12Mo2 | X5CrNiMo18.10 | SUS316 | 316 | S31600 | 30316 | 20,20a |

| 21 | 1Cr17Ni12Mo2 | ||||||

| 22 | 0Cr18Ni12Mo2Ti | X10CrNiMoTi18.10 | |||||

| 23 | 1Cr18Ni12Mo2Ti | X10CrNiMoTi18.10 | |||||

| 24 | 00Cr17Ni14Mo2 | X2CrNiMo18.10 | SUS316L | 316L | S31603 | 30316L | 19,19a |

| 25 | 0Cr17Ni12Mo2N | SUS316N | 316N | S31651 | |||

| 26 | 00Cr17Ni13Mo2N | X2CrNiMoNi18.12 | Tlhaloso: SUS316LN | 316LN | S31653 | ||

| 27 | 0Cr18Ni12Mo2Cu2 | SUS316J1 | |||||

| 28 | 00Cr18Ni14Mo2Cu2 | SUS316J11 |