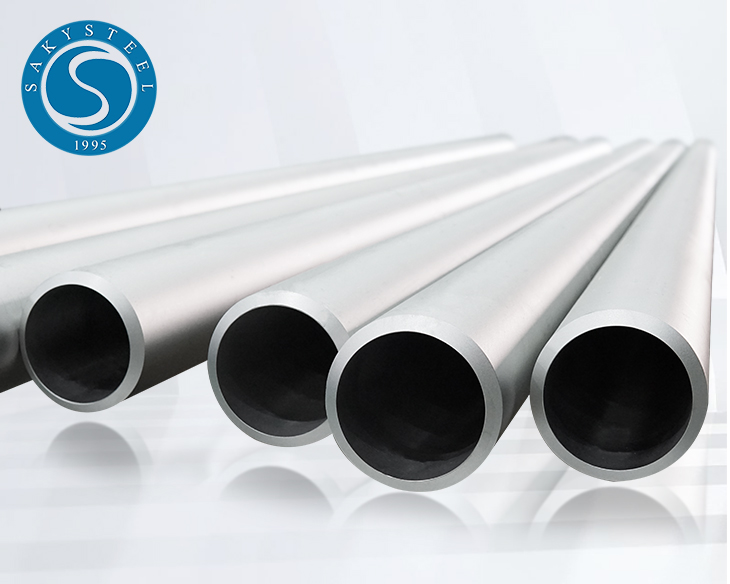

Tubus chalybis inoxidabilis 304 316

Descriptio Brevis:

| Specificationesfistula chalybis inoxidabilis:: |

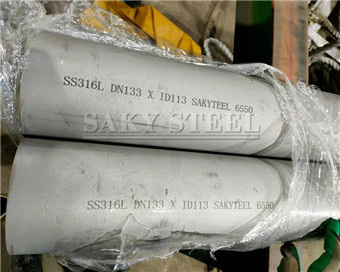

Magnitudo Tuborum et Fistularum Sinuosarum:1 / 8″ NB – 12″ NB

Specificationes:ASTM A/ASME SA213, A249, A269, A312, A358, A790

Norma:ASTM, ASME

Gradus:304,310, 310S, 314, 316, 316, 321, 347, 904L, 2205, 2507.

Technicae:Calido laminatum, frigido tractum

Longitudo:5.8M, 6M, 12M et Longitudo Requisita

Diameter externus:6.00 mm diametro externo usque ad 914.4 mm diametro externo

Crassitudo :0.6 mm ad 12.7 mm

Ordo temporum:SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS

Genera:Tubi Sinsurati

Forma:Tubi Rotundi, Quadrati, Rectanguli, Hydraulici, Acuti

Finis:Extremum Planum, Extremum Oblinatum, Calcatum

| Tubi Sinsurati Chalybis Inoxidabilis 316 / 316L Gradus Aequivalentes: |

| NORMA | OPUS NUM. | UNS | JIS | BS | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S1 | 58E | |

| SS 316 | 1.4401 | S31600 | SUS 316 | 304S11 | - | 58E |

| Tuborum sine suturis SS 304 / 316L, compositio chemica et proprietates mechanicae: |

| Gradus | C | Mn | Si | P | S | Cr | Mo | Ni |

| S30400 | 0.08 maximum | 2.0 maximum | 1.00 maximum | 0.045 maximum | 0.030 maximum | 18.00 – 20.00 | 8.00 – 11.00 | |

| S31600 | 0.035 maximum | 2.0 maximum | 1.00 maximum | 0.045 maximum | 0.030 maximum | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 |

| Gradus | Punctum Liquefactionis | Robur Tensilis | Robur Cedendi (0.2%Offset) |

| 304 | 1040°C (1900°F) | MPa – 515 | MPa – 205 |

| CCCXVI | 1100-1170°C (2010-2140°F) | MPa – 515 | MPa – 205 |

| Cur Nos Eligas? |

1. Materiam perfectam secundum necessitatem tuam minimo pretio adipisci potes.

2. Pretia etiam "Reworks", FOB, CFR, CIF, et traditionis ostium ad ostium offerimus. Suademus ut pactum vecturae facias, quod satis oeconomicum erit.

3. Materiae quas praebemus omnino verificabiles sunt, ab ipso certificato probationis materiae rudis ad declarationem dimensionalem finalem. (Relationes secundum requisitum apparebunt)

4. spondemus te responsum intra horas viginti quattuor daturum esse (plerumque eadem hora).

5. Alternativas ex promptu, traditiones officinarum cum tempore fabricationis minimo accipere potes.

6. Clientibus nostris plene dediti sumus. Si, omnibus optionibus examinatis, postulatis vestris satisfacere non poterit, vos non decipiemus falsis promissis, quae bonas necessitudines cum clientibus creabunt.

| Cura Qualitatis (tam Destructivam quam Non Destructivam comprehendens): |

1. Examen Dimensionis Visualis

2. Examinationes mechanicae sicut tensile, elongatio et areae reductio.

3. Experimentum magnae scalae

4. Analysis examinationis chemicae

5. Examen duritiae

6. Examen tutelae contra foveas

7. Examinatio Flaring

8. Experimentum Aquae Iactae

9. Examen Penetrationis

10. Examen radiographicum

11. Examen Corrosionis Intergranularis

12. Analysis impactus

13. Currentis turbulenti examinatio

14. Analysis hydrostatica

15. Experimentum Metallographiae

| Involucrum: |

1. Involucrum magni momenti est, praesertim in casu vecturarum internationalium ubi consignatio per varias vias transeunt ad destinationem finalem perveniendum, itaque curam specialem involucrorum adhibemus.

2. Saky Steel merces nostras multis modis secundum producta convasat. Nos merces nostras multis modis convasamus, exempli gratia,

Involucrum contractile

Capsae cartoneae

Palettae ligneae

Arcae ligneae

Arcae ligneae

| Applicationes: |

1. Societates Chartae et Pulpae

2. Applicationes Altae Pressionis

3. Industria Petrolei et Gasii

4. Refinaria Chemica

5. Ductus

6. Applicatio Altae Temperaturae

7. Tubus Aquarius Linea

8. Centrales Energiae Nuclearis

9. Industriae Ciborum Processus et Lacticiniorum

10. Caldaria et Permutatores Caloris

| Plura detalia: |

| SN | (GB) | (DIN) | (JIS) | AISI/ASTM | UNS | SAE | (ISO) |

| 1 | 1Cr17Mn6Ni5N | SUS201 | 201 | S20100 | 30201 | A-2 | |

| 2 | 1Cr18Mn8Ni5N | X8CrMnNi189 | SUS202 | 202 | S20200 | 30202 | A-3 |

| 3 | 1Cr18Mn10Ni5Mo3N | ||||||

| 4 | 2Cr13Mn9Ni4 | ||||||

| 5 | 1Cr17Ni7 | X12CrNi17.7 | SUS301 | 301 | S30100 | 30301 | 14 |

| 6 | 1Cr17Ni8 | X12CrNi17.7 | SUS301J1 | ||||

| 7 | 1Cr18Ni9 | X12CrNi18.8 | SUS302 | 302 | S30200 | 30302 | 12 |

| 8 | Y1Cr18Ni9 | X12CrNiSi18.8 | SUS303 | 303 | S30300 | 30303 | 17 |

| 9 | Y1Cr18Ni9Se | SUS303Se | 303Se | S30323 | 30303Se | 17 | |

| 10 | 1Cr18Ni9Si3 | X12CrNiSi18.8 | SUS302B | 302B | S30215 | 30302B | |

| 11 | 0Cr18Ni9 | X5CrNi18.9 | SUS304 | 304 | S30400 | 30304 | 11 |

| 12 | 00Cr18Ni10 | X2CrNi18.9 | SUS304L | 304L | S30403 | 30304L | 10 |

| 13 | 0Cr19Ni9N | SUS404N1 | 304N | S30451 | |||

| 14 | 0Cr19Ni10NbN | X5CrNiNb18.9 | SUS304N2 | XM21 | S30452 | ||

| 15 | 00Cr18Ni10N | X2CrNiN18.10 | SUS304LN | 304LN | S30453 | ||

| 16 | 1Cr18Ni12 | X5CrNi19.11 | SUS305 | CCCV | S30500 | 30305 | 13 |

| 17 | 0Cr18Ni12 | X5CrNi19.11 | |||||

| 18 | 0Cr23Ni13 | X7CrNi23.14 | SUS309S | ||||

| 19 | 0Cr25Ni20 | SUS310S | |||||

| 20 | 0Cr17Ni12Mo2 | X5CrNiMo18.10 | SUS316 | CCCXVI | S31600 | 30316 | 20, 20a |

| 21 | 1Cr17Ni12Mo2 | ||||||

| 22 | 0Cr18Ni12Mo2Ti | X10CrNiMoTi18.10 | |||||

| 23 | 1Cr18Ni12Mo2Ti | X10CrNiMoTi18.10 | |||||

| 24 | 00Cr17Ni14Mo2 | X2CrNiMo18.10 | SUS316L | 316L | S31603 | 30316L | 19, 19a |

| 25 | 0Cr17Ni12Mo2N | SUS316N | 316N | S31651 | |||

| 26 | 00Cr17Ni13Mo2N | X2CrNiMoNi18.12 | SUS316LN | 316LN | S31653 | ||

| 27 | 0Cr18Ni12Mo2Cu2 | SUS316J1 | |||||

| 28 | 00Cr18Ni14Mo2Cu2 | SUS316J11 |