Stainless hlau Hollow Bar

Lus piav qhia luv luv:

Nrhiav rau Stainless Hlau Hollow Bars? Peb muab seamless thiab welded stainless hlau hollow tuav nyob rau hauv 304, 316, thiab lwm yam qib.

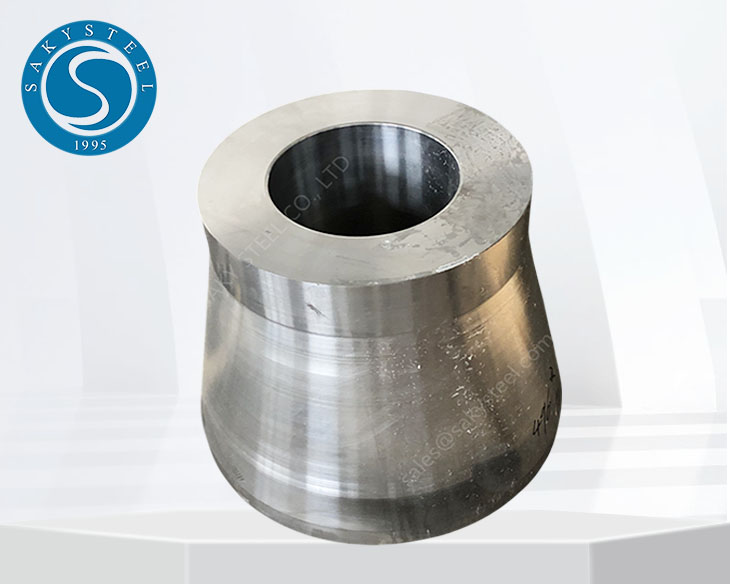

Stainless hlau Hollow Bar:

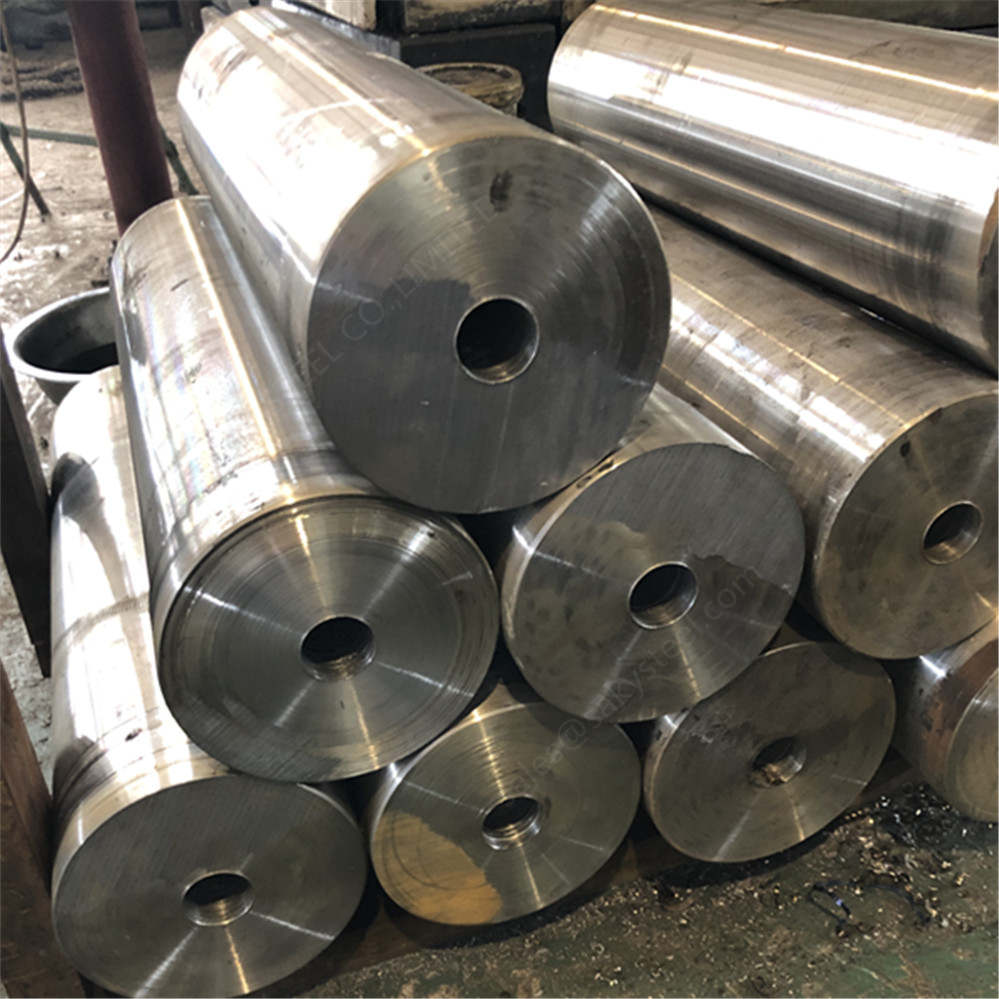

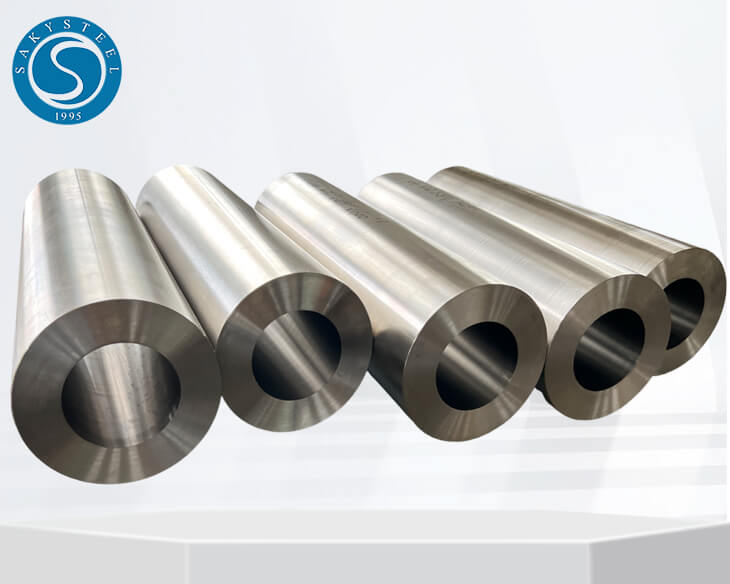

Lub hollow bar yog hlau bar featuring lub hauv paus bore uas txuas mus rau nws tag nrho ntev. Manufactured zoo ib yam li seamless hlab, nws yog extruded los ntawm ib tug forged bar thiab ces precision-txiav mus rau qhov xav tau zoo. Txoj kev tsim khoom no txhim kho cov khoom siv kho tshuab, feem ntau ua rau muaj kev sib xws ntau dua thiab txhim kho kev cuam tshuam toughness piv rau dov lossis forged Cheebtsam. Tsis tas li ntawd, hollow tuav muaj qhov zoo ntawm qhov tseeb thiab qhov sib xws, ua rau lawv muaj kev ntseeg siab rau cov ntawv thov uas xav tau kev ua haujlwm siab thiab raug.

Specifications ntawm Stainless Hlau Hollow Bar

| Txuj | ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311, DIN 1654-5, DIN 17440, KS D3706, GB / T 1220 |

| Khoom siv | 201, 202, 205, XM-19 thiab lwm yam. 301, 303, 304, 304L, 304H, 309S, 310S, 314,316,316L, 316Ti, 317,321,321H, 329,330,348 thiab lwm yam. 409,410,416,420,430,430F,431,440 2205,2507,S31803,2209,630,631,15-5PH,17-4PH,17-7PH,904L,F51,F55,253MA thiab lwm yam. |

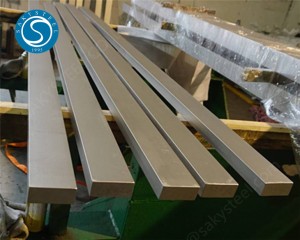

| Nto | Bright, Polishing, Pickled, Peeled, Dub, Sib Tsoo, Zeb, Daim iav, Hairline thiab lwm yam |

| Technology | Cold Drawn, Kub Rolled, Forged |

| Specifications | raws li xav tau |

| Ua siab ntev | H9, H11, H13, K9, K11, K13 los yog raws li xav tau |

Ntau cov ntsiab lus ntawm Stainless hlau hollow bar

| SIZE (mm) | MOQ (kgs) | SIZE (mm) | MOQ (kgs) | SIZE (mm) | MOQ (kgs) |

| 32 x16 32 x 20 32 x 25 36 x16 36 x 20 36 x 25 40 x 20 40 x 25 40 x28 45 x 20 45 x 28 45 x 32 50 x 25 50 x32 50 x36 56 x 28 56x36 ib 56 x 40 63x32 ib 63 x 40 6 3x50 71x36 ib 71x45 ib 71x56 ib 7 5x40 75x5 0 75x60 ua 80 x40 80 x50 | 200 kgs | 80x63 ib 85x4 5 8 5x5 85x67 ua 90 x50 90x56 ib 90x63 ib 90x71 ib 95x5 0 100 x 56 100 x 71 100 x 80 106x56 ib 106x71 ib 106 x 80 112x63 ib 112x71 ib 112 x 80 112 x 90 118 x 63 118 x 80 118 x 90 125 x 71 125 x 80 125 x 90 125 x 100 132x71 ib 132 x 90 132 x 106 | 200 kgs | 140 x 80 140 x 100 140 x 112 150 x 80 150 x 106 150 x 125 160 x 90 160 x 112 160 x 132 170 x 118 170 x 140 180 x 125 180 x 150 190 x 132 190 x 160 200 x 160 200 x 140 212 x 150 212 x 170 224 x 160 224 x 180 236x170 ib 236x190 ib 250 x 180 250 X 200 305 X 200 305 X 250 355 x 25 5 355 X 300 | 350kgs ua |

| Lus Cim: OD x ID (mm) | |||||

| Loj | Chucked tseeb rau OD | Chucked muaj tseeb rau ID | |||

| OD, | ID, | Max. OD, | Max ID, | Min.OD, | Min. ID, |

| mm | mm | mm | mm | mm | mm |

| 32 | 20 | 31 | 21.9 ib | 30 | 21 |

| 32 | 16 | 31 | 18 | 30 | 17 |

| 36 | 25 | 35 | 26.9 ib | 34.1 ib | 26 |

| 36 | 20 | 35 | 22 | 34 | 21 |

| 36 | 16 | 35 | 18.1 | 33.9 ib | 17 |

| 40 | 28 | 39 | 29.9 ib | 38.1 ib | 29 |

| 40 | 25 | 39 | 27 | 38 | 26 |

| 40 | 20 | 39 | 22.1 | 37.9 ib | 21 |

| 45 | 32 | 44 | 33.9 ib | 43.1 ib | 33 |

| 45 | 28 | 44 | 30 | 43 | 29 |

| 45 | 20 | 44 | 22.2 | 42.8 ib | 21 |

| 50 | 36 | 49 | 38 | 48 | 37 |

| 50 | 32 | 49 | 34.1 ib | 47.9 ib | 33 |

| 50 | 25 | 49 | 27.2 ib | 47.8 ib | 26 |

| 56 | 40 | 55 | 42 | 54 | 41 |

| 56 | 36 | 55 | 38.1 ib | 53.9 ua | 37 |

| 56 | 28 | 55 | 30.3 | 53.7 ib | 29 |

Kev siv ntawm Stainless Hlau Hollow Bar

1.Oil & Gas Kev Lag Luam: Siv rau hauv cov cuab yeej drilling, cov cuab yeej siv lub taub hau, thiab cov txheej txheem sab nrauv vim lawv cov kav ntev thiab tsis kam mus rau qhov hnyav ib puag ncig.

2.Automotive & Aerospace: Zoo tagnrho rau lub teeb yuag structural Cheebtsam, shafts, thiab hydraulic thooj voos kheej kheej uas yuav tsum tau muaj zog thiab tej yam kuj.

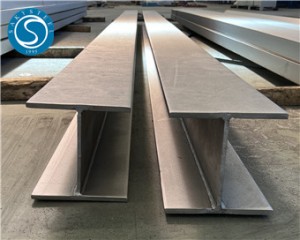

3.Construction & Infrastructure: Siv nyob rau hauv architectural moj khaum, txuas hniav, thiab kev txhawb nqa cov qauv uas corrosion kuj thiab lub zog yog qhov tseem ceeb.

4.Machinery & Khoom: Siv nyob rau hauv precision-engineered qhov chaw xws li hydraulic thiab pneumatic cylinders, tsav ncej, thiab bearings.

5.Food & Pharmaceutical Processing: Zoo siab rau kev siv tu cev xws li cov tshuab conveyor, cov cuab yeej ua haujlwm, thiab cov tso tsheb hlau luam vim lawv qhov chaw tsis zoo.

6.Marine Kev Lag Luam: Siv nyob rau hauv nkoj tsim thiab offshore platforms, muab kev tiv thaiv zoo rau dej ntsev corrosion.

Cov yam ntxwv tshwj xeeb ntawm Stainless Hlau Hollow Bar

Thawj qhov sib txawv ntawm stainless hlau hollow bar thiab seamless raj yog nyob rau hauv phab ntsa thickness. Thaum cov raj tau tsim tshwj xeeb rau kev thauj cov dej thiab feem ntau tsuas yog xav tau kev ua haujlwm ntawm qhov kawg rau fittings lossis cov khoom sib txuas, hollow tuav muaj cov phab ntsa tuab tuab kom haum rau kev ua haujlwm ntxiv rau hauv cov khoom tiav.

Kev xaiv rau hollow tuav es tsis txhob siv cov khoom tuav muaj qhov zoo meej, nrog rau cov khoom siv thiab cov cuab yeej txuag nqi, txo lub sij hawm ua haujlwm, thiab txhim kho cov khoom tsim tau. Txij li cov hollow tuav tau ze rau qhov kawg cov duab, cov khoom siv tsawg dua yog khib nyiab, thiab cov cuab yeej siv tau tsawg. Qhov no txhais tau tias txo tus nqi tam sim ntawd thiab siv cov peev txheej zoo dua.

Qhov tseem ceeb tshaj, txo qis los yog tshem tawm cov kauj ruam machining tseem ceeb txhim kho kev tsim khoom. Qhov no tuaj yeem ua rau txo qis cov nqi ua haujlwm ib feem lossis muaj peev xwm ntau lawm thaum cov tshuab ua haujlwm ntawm lub peev xwm. Tsis tas li ntawd, siv stainless hlau hollow tuav tshem tawm qhov xav tau rau trepanning thaum tsim cov khoom nrog lub hauv paus bore - ib qho kev lag luam uas tsis tsuas yog hardens cov khoom tab sis kuj ua rau cov txheej txheem machining nyuaj.

Vim li cas thiaj xaiv peb?

•Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

•Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

•Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

•Peb lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

•Muab SGS TUV daim ntawv qhia.

•Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

•Muab kev pabcuam ib-nres.

Ntim:

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj dhau los ntawm ntau txoj kev mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel ntim peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,