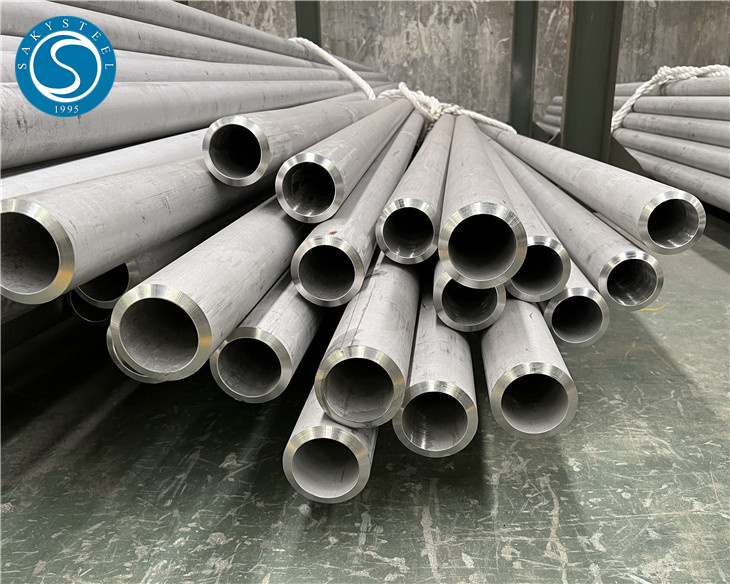

316 Seamless Stainless simbi pombi

Tsanangudzo Pfupi

| Zvinotsanangurwa zvesimbi isina musono pombi: |

Seamless Pipes & Tubes Size:1 / 8″ NB – 24″ NB

Specifications :ASTM A/ASME SA213, A249, A269, A312, A358, A790

Standard :ASTM, ASME

Giredhi:304, 316, 321, 321Ti, 420, 430, 446, 904L, 2205, 2507

MatekinikiKupisa-kwakakungurutswa, kunotonhorera

Urefu :5.8M, 6M & Inodiwa Urefu

Outer Diameter6.00 mm OD kusvika 914.4 mm OD, Size kusvika 24” NB

Thickness :0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Chirongwa :SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Types :Seamless Pipes

Fomu :Round, Square, Rectangle, Hydraulic, Honed Tubes

End :Magumo Akachena, Magumo Akanaka, Akatsikwa

| SS 316 isina Musono Pipes Kemikari Kuumbwa: |

| Giredhi | C | Mn | Si | P | S | Cr | Ni |

| SS 316 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 16-18 | 0.10 |

| Stainless Simbi Pipe Mechanical Properties: |

| Giredhi | Tensile Simba (MPa) min | Goho Simba 0.2% Uchapupu (MPa) min | Elongation (% mu50mm) min | Kuoma | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

| Stainless Simbi Pipe Production process : |

Mufananidzo uyu unoratidza zvakakwanaisina musono pombi kugadzirwa muitiro, ine matanho masere akakosha: kugadzirira zvinhu mbishi, kuzora, kupinza, kukuya pamusoro, kuchenesa asidhi, kudhirowa kunotonhora, ultrasonic test, uye kurongedza kwekupedzisira. Imwe neimwe nhanho inodzorwa nekuchenjerera kuti ive nechokwadi chepamusoro-dimensional kurongeka, kupedzisa kwepamusoro kwepamusoro, uye mhando yemukati, ichisangana nezvinoda kuomesesa zvekushandisa kwemaindasitiri.

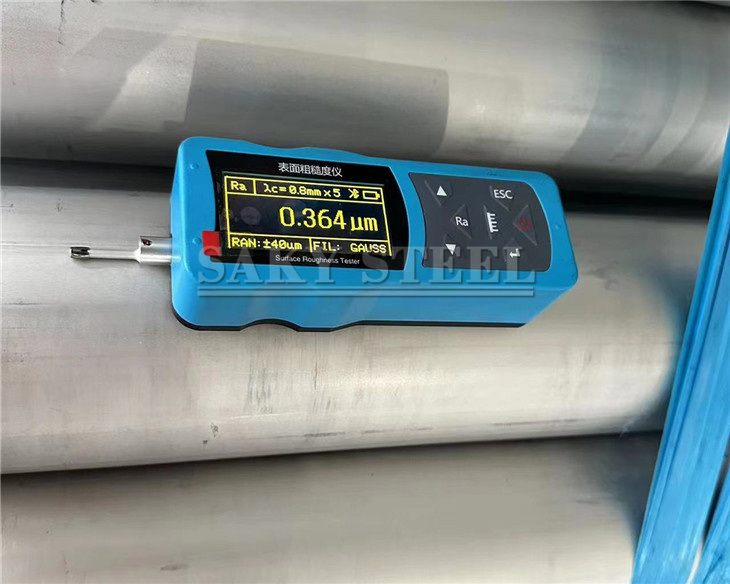

| 316 Stainless Simbi Pipe Roughness bvunzo: |

PaSAKY STEEL tinoedza kuomarara papombi dzesimbi isina simbi kuti tive nechokwadi chenzvimbo yakatsetseka uye inowirirana inosangana nezviyero zvepasi rose. Kushata kwepombi chinhu chakakosha chinokanganisa kuyerera kwekuita corrosion kuramba uye kuita kwese mumashandisirwo akakosha.

Isu tinoshandisa zviridzwa zvakaringana kuyera kushata kwepamusoro kuve nechokwadi chekuti mapaipi ese anosangana nezvinodiwa nemutengi kuti aite mushe uye kupera. Mapombi edu akanakira kugadzira chikafu chemakemikari emugungwa uye maindasitiri ezvimiro uko kunaka kwepamusoro kwakakosha.

|  |

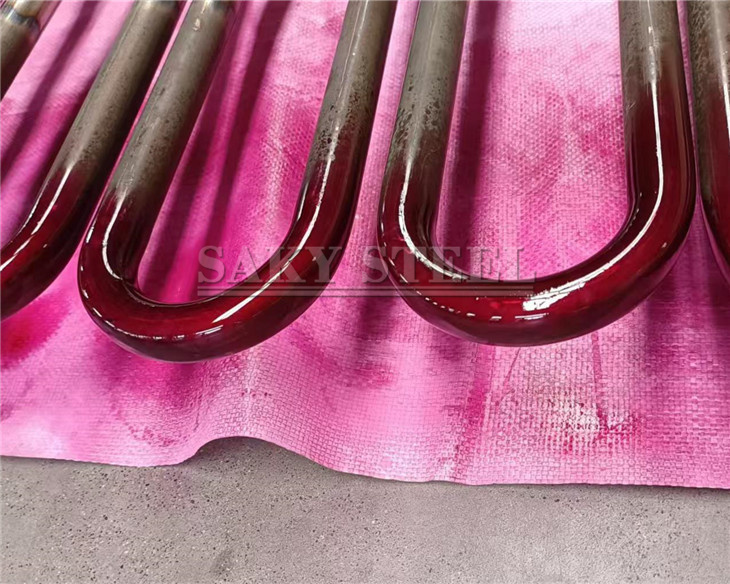

| Stainless Simbi Pipe Surface Test: |

Kupera kwepamusoro kwepombi dzesimbi isina tsvina kwakakosha pakuita uye kutaridzika. PaSAKY STEEL isu tinonyatso kudzora kunaka kwepasi kuburikidza nepamusoro pekuongorora maitiro. Mufananidzo wacho unoratidza kuenzanisa kwakajeka pakati pepombi dzepamusoro dzakaipa dzine hurema hunooneka uye mapaipi edu akanaka epamusoro ane kupera uye yunifomu kupera.

Mapombi edu esimbi asina simbi haana mahara kubva pakatsemuka makomba mavanga uye maredhi emakaki ekuona yakanakisa kusakara uye kuvimbika. Mapombi aya anoshandiswa zvakanyanya mumakemikari emugungwa uye zvimiro zvekushandisa uko kutendeseka kwepamusoro kunokosha.

| PT Test : |

SAKY STEEL inoita inopinza yekuyedza PT pamapombi esimbi isina tsvina uye zvikamu sechikamu chemaitiro edu akasimba ekudzora mhando. PT inzira isiri yekuparadza yekuyedza inoshandiswa kuona kuremerwa kwepasi senge cracks porosity uye inclusions isingaonekwe nemeso.

Vatariri vedu vakadzidziswa vanoshandisa zvemhando yepamusoro zvinopinda uye zvekuvandudza zvinhu kuti ive nechokwadi chechokwadi uye chakavimbika mhedzisiro. Ese maitiro ePT anotevera zviyero zvepasirese uye zvakatemwa nevatengi zvinovimbisa kuchengetedzwa kwechigadzirwa uye kuita.

|  |

| Sei Tisarudze: |

1. Unogona kuwana zvinhu zvakakwana maererano nezvinodiwa zvako pamutengo wakaderera.

2. Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekutumira pamusuwo kumasuo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

3. Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pazvitupa zvekuongorora zvinhu kusvika kune yekupedzisira dimensional statement.(Mishumo icharatidza pane zvinodiwa)

4. inovimbisa kupa mhinduro mukati memaawa makumi maviri nemana (kazhinji muawa imwe chete)

5. Unogona kuwana dzimwe nzira dzemasheya, kutakura zvigayo nekuderedza nguva yekugadzira.

6. Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

| Hunhu Husimbiso (kusanganisira zvese Zvinoparadza uye Zvisiri Kuparadza): |

1. Visual Dimension Test

2. Mechanical bvunzo senge tensile, Elongation uye kuderedzwa kwenzvimbo.

3. Muedzo mukuru

4. Kemikari yekuongorora kuongorora

5. Kuoma bvunzo

6. Pitting kudzivirira bvunzo

7. Flaring Testing

8. Mvura-Jet Test

9. Penetrant Test

10. X-ray test

11. Intergranular Corrosion Testing

12. Kuongorora kwemigumisiro

13. Eddy anoongorora

14. Hydrostatic analysis

15. Metallography Experimental Test

| Kurongedza: |

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko chinotakurwa chinopfuura nemumatanho akasiyana-siyana kuti chisvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,

Applications:

1. Pepa & Pulp Makambani

2. High Pressure Applications

3. Indasitiri yeOiri neGasi

4. Chemical Refinery

5. Pipeline

6. High Temperature Application

7. Mvura Pipe Lin

8. Zvigadzirwa zveNuclear Power Plants

9. Food Processing uye Dairy Industries

10. Boiler & Heat Exchangers