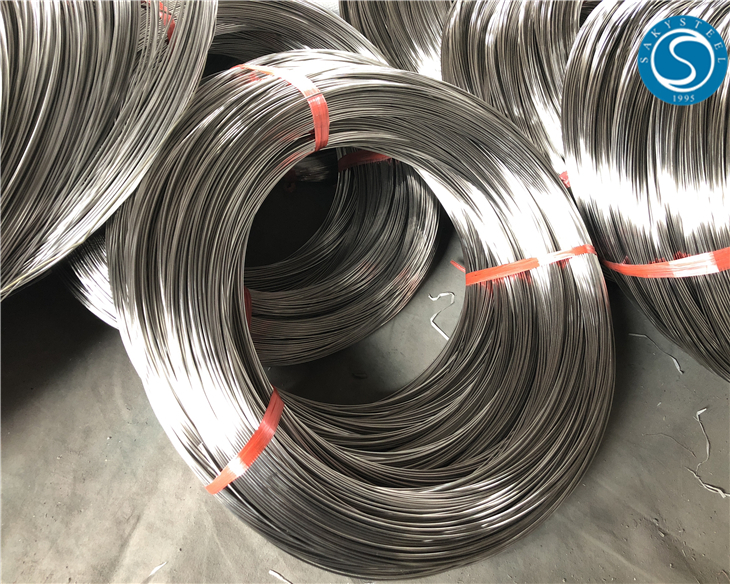

Hardness Steel Silig

Sharaxaad Gaaban:

| Faahfaahinta siligga birta ah ee adag: |

1) Fasalka: ASTM: 201, 202, 204Cu, 301, 302, 303, 304, 304Cu, 304HC, 304L, 304H, 310, 310S, 312, 314, 366, 3L 316LCu, 321, 410, 420, 430, 430L

DIN/EN: 1.4301, 1.4306, 1.4307, 1.4310, 1.4401, 1.4404, 1.4567, 1.4841. 1.4597, 1.4362, 1.4370, 1.4016

2) Halbeegga: GB, SUS, ASTM, AISI, EN, DIN, JIS, BS - sidoo kale heerarka caalamiga ah ee u dhigma.

3) Dhexroorka: 0.01-25mm

4) Dusha sare: dhalaalaya, daruur leh, cad, madow

5) Xaalad: silig adag

6) Nooca: Hydrogen, Qabow-sawir, Ciwaanka Qabow, Annealed

7) Baakadaha: gariiradda ama dabaasha

Xirmada 1.coil badiyaa waa 5,10,15,20,50,150,500KG/dufan.

2.ka buuxaan baco gudaha ah iyo bacaha tolmada leh ama kartoonada dibadda.

3. badan oo lagu soo raray sariirta, oo lagu duuduubay filim caag ah iyo fiilooyinka xidhidhka.

4.ama sida dalabkaaga.

| Darajooyinka silig birta ah ee engegnaanta |

| Nooca AISI | C Max % | Mn Max % | P Max% | S Max% | Si Max% | Cr% | Ni% | Mo% |

| 201 | 0.15 | 5.50-7.50 | 0.06 | 0.03 | 1 | 16.000-18.00 | 0.5 | - |

| 202 | 0.15 | 7.50-10.00 | 0.06 | 0.03 | 1 | 17.00-19.00 | 3.-0-5.00 | - |

| 204CU | 0.08 | 6.5-8.5 | 0.06 | 0.03 | 2 | 16.0-17.0 | 1.5-3.0 | - |

| 302 | 0.15 | 2 | 0.045 | 0.03 | 1 | 17.00-19.00 | 8.00-10.00 | - |

| 302HQ/ | 0.03 | 2 | 0.045 | 0.02 | 1 | 17.00-19.00 | 9.00-10.00 | - |

| 304CU | ||||||||

| 304HC | 0.04 | 0.80-1.70 | 0.04 | 0.015 | 0.3-0.6 | 18-19 | 8.5-9.5 | - |

| 303 | 0.07 | 2 | 0.045 | 0.25 Min | 1 | 17-19 | 8.0-10.0 | 0.6 |

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.00-20.00 | 8.0-10.50 | - |

| 304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.00-20.00 | 8.00-12.00 | - |

| 310 S | 0.055 | 1.5 | 0.04 | 0.005 | 0.7 | 25.0-28.0 | 19-22 | - |

| 314 | 0.25 | 2 | 0.045 | 0.03 | 1.50-3.00 | 23.00-26.00 | 19.00-22.00 | - |

| 316 | 0.06 | 2 | 0.045 | 0.03 | 1 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 |

| 316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 |

| 316Ti | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 |

| 347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.00-19.00 | 9.00-13.00 | - |

| 321 | 0.06 | 2 | 0.045 | 0.01 | .40-.60 | 17-19.00 | 9.4-9.6 | - |

| 308 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17-19 | 9.5-13.0 | - |

| 308L | 0.025 | 1.50/2.00 | 0.025 | 0.02 | 0.5 | 19.0/21.0 | 9.5/11.0 | - |

| 309 | 0.08 | 1.50 / 2.50 | 0.02 | 0.015 | 0.5 | 23.0/25.0 | 20.0/14.0 | - |

| 309L | 0.025 | 1.50 / 2.50 | 0.02 | 0.015 | 0.5 | 23.0/25.0 | 12.0/14.0 | - |

| 316L | 0.02 | 1.50/2.00 | 0.02 | 0.02 | 0.5 | 18.0/20.0 | 12.00-14.00 | 2.00-3.00 |

| 430L | 0.03 | 1 | 0.04 | 0.03 | 1 | 16.00-18.00 | - | |

| 434 | 0.08 | 1 | 0.04 | 0.03 | 1 | 16.00-18.00 | - | 0.90-1.40 |

Codsiga :Stainless Steel si ballaaran u isticmaali kartaa Warshadaha, Dhismayaasha, Qurxinta, Life, Medical, Gaadiidka, Warshadaha Kiimikada, tamarta qorraxda, Marine, Duulista, iwm.

Isticmaalka Alaabta: Xarkaha guga SS ee loo isticmaalo guga, birta, xadhiga, burushka, dib u habeynta, tayada polishing electro, pin, toosan iyo baararka la jaray, silig birta go'an, dariiqa gaadhiga, mesh bir ah, sawirida silig, mesh tolida, tuubada, xadhig silig, qalabka sifaynta, birta strand, qalabka elektarooniga ah, daawaynta, ciidanka isticmaalka alaabta rasaasta, qalabka ilaalinta, ka hortagga= ololka alaabta jikada, iwm.

Tags Kulul: Soosaarayaasha siliga birta ah ee adag, alaab-qeybiyeyaasha, qiimaha, iibka