Warshadaha petrochemical, daxalka dhuumaha ayaa khatar weyn ku ah badbaadada shaqada, ilaalinta deegaanka, iyo hufnaanta dhaqaalaha. Dhuumaha inta badan waxay qaadaan walxaha wasakhaysan sida saliida ceyriinka ah, gaaska dabiiciga ah, xeryahooda baaruudka, acids, iyo alkalis, taasoo ka dhigaysa ka hortagga daxalka dhuumaha mudnaanta injineernimada. Maqaalkani waxa uu sahamiyaa tabaha ugu waxtarka badan ee ka hortagga daxalka ee dhuumaha petrochemical, daboolaya xulashada walxaha, ilaalinta dusha sare, ilaalinta cathodic, iyo la socodka daxalka.

Xulashada Qalabka: Safka Koowaad ee Difaaca

Doorashada walxaha u adkaysta daxalka waxay si weyn u kordhisaa nolosha adeegga dhuumaha. Ikhtiyaarada caadiga ah waxaa ka mid ah:

| Qalab | Nooca | Astaamaha Muhiimka ah | Deegaanka Codsiga |

|---|---|---|---|

| 316L | Austenitic Stainless Steel | Iska caabin godad wanaagsan; alxanka leh | Warbaahin acidic ah, soo-gaadhista chloride |

| S32205 / S32750 | Duplex / Super Duplex | Xoog sare, iska caabin koloriin heer sare ah | Xeebta, dhuumaha brine |

| Inconel 625/825 | Alloy Nickel | Iska caabin aan caadi ahayn ee asiidhyada iyo alkalisyada xooggan | Desulfurization, nidaamyada heerkulka sare |

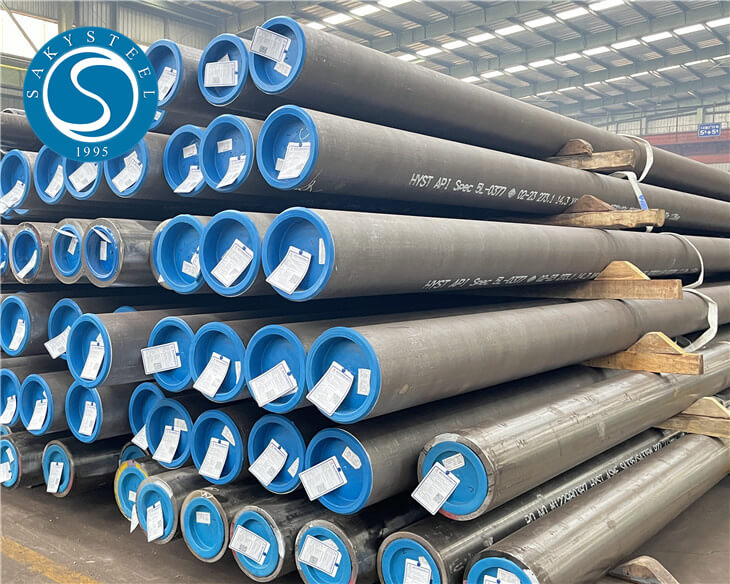

| Birta Kaarboonka ee Dahaarka leh | Bir la safeeyey | Kharash-ku-ool ah, daxalka lagu ilaaliyo dahaarka | Saliid sulfur-qani ah, khadadka cadaadiska hooseeya |

Dahaarka dusha sare: Caqabad jidheed oo ka hortagaysa daxalka

Dahaarka dibadda iyo gudaha ayaa bixiya xannibaad ilaalin ah si ay u xannibaan walxaha daxalka ah:

Dahaarka epoxy tar dhuxusha:Habka dhaqameed ee dhuumaha la aasay.

• Epoxy Fusion Bonded (FBE):Iska caabin heerkul sare ah iyo adhesion xooggan.

• 3-Lakabka PE / PP Dahaarka:Si ballaaran loo isticmaalo dhuumaha gudbinta masaafada fog.

Dahaarka gudaha: Yaree caabbinta dareeraha kana ilaali daxalka gidaarka gudaha.

Diyaarinta saxda ah ee dusha sare iyo codsiga ayaa muhiim u ah waxtarka dahaarkan.

Ilaalinta Cathodic: Tignoolajiyada Ka-hortagga Daxalka Korantada

Ilaalinta Cathodic waxay ka hortagtaa daxalka korantada iyadoo ku qasbaysa dusha dhuumaha inay u dhaqmaan sidii cathode:

Nidaamka Anode-ka Allabari: Wuxuu isticmaalaa zinc, magnesium, ama aluminium anodes.

Nidaamka Hadda La Yaqaanay: Wuxuu adeegsadaa ilo koronto oo dibadda ah si uu hadda u isticmaalo.

Habkan waxaa caadi ahaan loo adeegsadaa dhuumaha dhulka hoostiisa ku duugan iyo kuwa badda hoose, oo inta badan lagu daro dahaarka waxqabadka ugu wanaagsan.

Kormeerka iyo Dayactirka Daxalka

Kormeerka joogtada ahi waxa uu suurtageliyaa in goor hore la ogaado daxalka, yaraynta khataraha fashilka:

• Tijaabooyin iska caabin koronto ah iyo la socodka qaylada korantada ee falanqaynta wakhtiga dhabta ah;

• Qiyaasta Dhumucda Ultrasonic ee ogaanshaha khafiifinta derbiga;

• Kuubannada Daxalka ee qiimaynta heerka daxalka muddo ka dib.

Dejinta kormeerada joogtada ah, jadwalka nadiifinta, iyo daawaynta kiimikaad waxay caawisaa ilaalinta daacadnimada dhuumaha.

U hoggaansanaanta Heerarka Warshadaha

Hubi in qaabaynta dhuumahaaga iyo xeeladaha ilaalinta ay la socdaan xeerarka caalamiga ah:

TS EN ISO 21809 Heerarka dahaarka dibedda ee dhuumaha ee warshadaha batroolka iyo gaaska dabiiciga

NACE SP0169 - Shuruudaha ilaalinta Cathodic;

API 5L / ASME B31.3 - Dhuumaha khadka iyo habsocodka heerarka dhismaha tuubooyinka.

Gabagabo: Habka Isku-dhafan ee Ilaalinta Muddada Dheer

Ilaalinta daxalka dhuumaha ee waxtarka leh waxay u baahan tahay istaraatiijiyad dhinacyo badan leh, oo ay ku jiraan:

• Xulashada agabka wanaagsan,

• Nidaamyada dahaarka adag,

• Ilaalinta firfircoon ee cathodic, iyo

• Barnaamijyada la socodka iyo dayactirka la isku halayn karo.

Adiga oo qaadanaya nidaamka maaraynta daxalka oo dhamaystiran, hawl-wadeenada batroolka waxa ay yareeynayaan xidhitaannada aan qorshaysnayn, kordhinta cimriga hantida, oo ay xaqiijiyaan badbaado, hawlo hufan.

Waqtiga boostada: Meey-27-2025