253MA / UNS30815 Ipuleti

Incazelo emfushane:

| Imininingwane ye-2Idatha ye-53MA: |

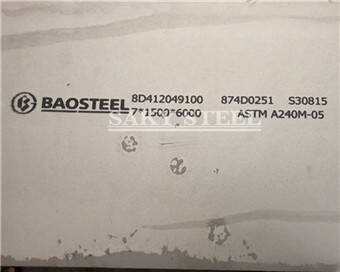

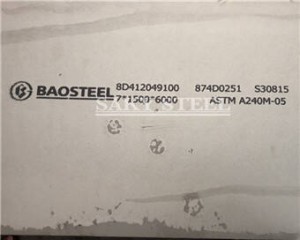

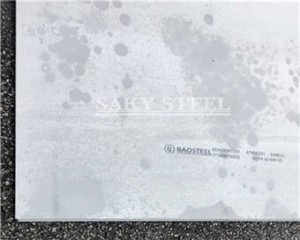

Imininingwane :ASTM A240 / ASME SA240

Ibanga:253SMA, S31803, S32205, S32750

Ububanzi :1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, njll.

Ubude :2000mm, 2440mm, 3000mm, 5800mm, 6000mm, njll.

Ubukhulu :0.3 mm kuya ku-50 mm

Ubuchwepheshe :Ipuleti eligoqiwe elishisayo (HR), ishidi eligoqiwe elibandayo (CR)

I-Surface Finish :2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, hair line, sand blast, Brush, SATIN (Met with Plastic Coated) njll.

I-Raw Materail:POSCO, Acerinox, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, Saky Steel, Outokumpu

Ifomu :Ishidi Elingenalutho, Ipuleti, Amafulethi, njll.

| Insimbi Engagqwali 253MA AmaSpredishithi namaPlate Amabanga Alinganayo: |

| IZINGA | I-WERKSTOFF NR. | EN Ukuqokwa | I-UNS |

| 253MA | 1.4835 | X9CrSiNCe21-11-2 | I-S30815 |

| 253MAAmaSpredishithi, Ukwakheka Kwamakhemikhali Amacwecwe kanye Nezakhiwo Zemishini(saky steel): |

| Ibanga | C | Cr | Mn | Si | P | S | N | Ce | Fe | Ni |

| 253MA | 0.05 - 0.10 | 20.0-22.0 | 0.80 ubuningi | 1.40-2.00 | 0.040 ubuningi | 0.030 ubuningi | 0.14-0.20 | 0.03-0.08 | Ibhalansi | 10.0-12.0 |

| Amandla Okuqina | Amandla Esivuno (0.2%Offset) | Ubude (ku-2 in.) |

| Psi:87,000 | Psi 45000 | 40 % |

| Kungani Usikhethe: |

1. Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani inani elingenzeka.

2. Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokudiliva umnyango nomnyango. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

3. Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina.(Imibiko izovela ngokwemfuneko)

4. isiqinisekiso sokunikeza impendulo phakathi namahora angu-24(imvamisa ngehora elifanayo)

5. Ungathola ezinye izindlela zesitoko, ukulethwa komshini ngokunciphisa isikhathi sokukhiqiza.

6. Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

| Ukuqinisekisa Ikhwalithi Ye-SAKY STEEL (okuhlanganisa kokubili Okubhubhisayo Nokungabhidlizi) : |

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Ukuhlaziywa komthelela

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Ukuhlolwa Okungenele

8. I-Intergranular Corrosion Testing

9. Ukuhlolwa Kokuqina

10. Ukuhlolwa Kokuhlola Kwe-Metallography

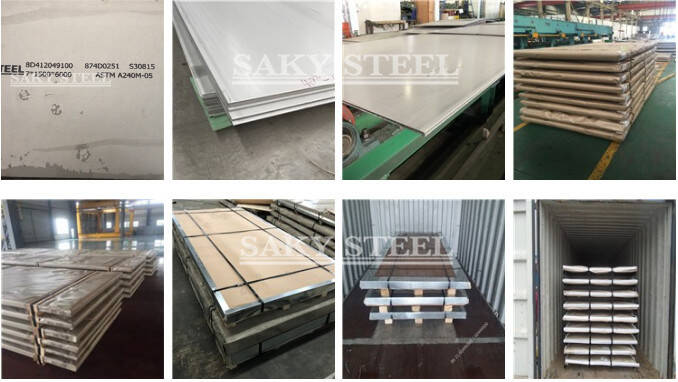

| Iphakheji ye-SAKY STEEL'S: |

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,

I-alloy engu-253Ma inezici ezilandelayo:

I-253MA iyinsimbi engagqwali ye-austenitic ekwazi ukumelana nokushisa eyenzelwe izinhlelo zokusebenza ezidinga amandla aphezulu okukhasa kanye nokumelana nokugqwala okuhle. Izinga lokushisa layo lokusebenza liyi-850 ~ 1100 °C.

Ukwakheka kwamakhemikhali kwe-253MA kuyalinganisela, okwenza insimbi ibe nezakhiwo ezifanele kakhulu ezibanzi ebangeni lokushisa lika-850 °C-1100 °C, ukumelana ne-oxidation ephakeme kakhulu, futhi izinga lokushisa lesikali lifinyelela ku-1150 °C; ukumelana ne-creep ephezulu kakhulu Amandla namandla okuqhekeka kwe-creep; ukumelana kahle nokugqwala kokushisa okuphezulu kanye nokumelana nokugqwala kwebhulashi emithonjeni eminingi yamagesi; amandla okukhiqiza okuphezulu namandla okuqina emazingeni okushisa aphezulu; ukuhleleka okuhle nokushisela Kanye nokusebenziseka okwanele.

Ngaphezu kwezakhi ze-alloying i-chromium ne-nickel, insimbi engagqwali engu-253MA iphinde ibe nenani elincane lensimbi yomhlaba engavamile (Izinsimbi Zomhlaba Ezingavamile, i-REM), ethuthukisa kakhulu amandla ayo okulwa ne-antioxidant. I-nitrogen yengezwa ukuthuthukisa izakhiwo ezinwabuzelayo futhi wenze le nsimbi ibe yi-austenite ephelele. Nakuba okuqukethwe kwe-chromium ne-nickel kuphansi uma kuqhathaniswa, le nsimbi engagqwali inezici eziningi zokushisa ezifanayo njengensimbi ephezulu ye-alloy alloy kanye ne-nickel-based alloy.

253Ma izicelo:

I-253MA isetshenziswa kabanzi emishinini yokucwilisa, imishini yesithando somlilo, ukuncibilika kwensimbi, isithando somlilo kanye nemishini yokuphonsa eqhubekayo, izigayo zokugawula (izithando zokushisa), izithando zokushisa ukushisa nezinye izinto, imishini yamaminerali kanye nemishini yokukhiqiza usimende.