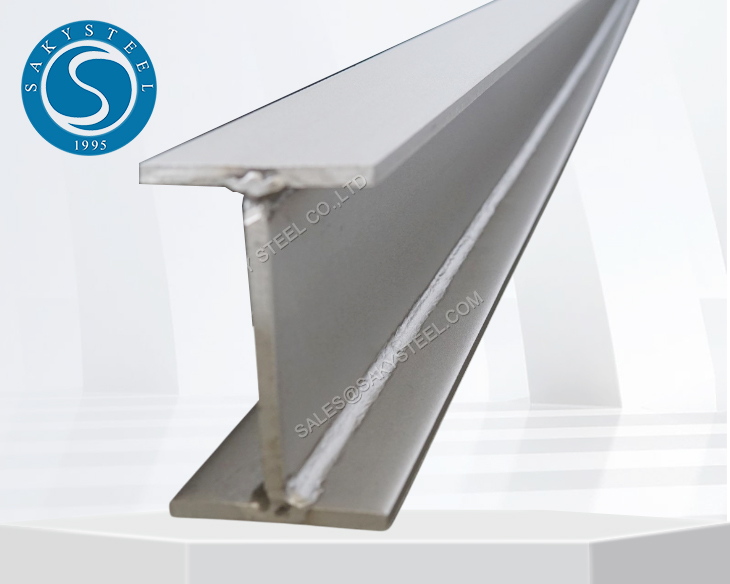

Insimbi Engagqwali I Beam

Incazelo emfushane:

Hlola i-premium Stainless Steel I Beams e-SakySteel. Ilungele ukwakhiwa, izicelo zezimboni, nokuningi.

I-Stainless Steel I Beam:

I-Stainless Steel I Beam iyingxenye yesakhiwo esinamandla aphezulu evame ukusetshenziswa ekwakhiweni nasekusetshenzisweni kwezimboni. Yenziwe ngensimbi engagqwali eqinile, inikeza ukumelana okuphakeme nokugqwala, iqinisekisa ukusebenza okuhlala isikhathi eside ngisho nasezimweni ezinzima. Ngesilinganiso sayo esiphelele samandla nesisindo, ilungele ukusekela imithwalo esindayo emabhulohweni, ezakhiweni nasemishinini. Itholakala ngosayizi namabanga ahlukahlukene, Imishayo Yensimbi Engagqwali Ingenziwa ngendlela oyifisayo ukuze ihlangabezane nezidingo ezithile zanoma iyiphi iphrojekthi, ihlinzeka ngosekelo lwesakhiwo oluthembekile nolusebenzayo.

Imininingwane ye-I-beam:

| Ibanga | 302 304 304L 310 316 316L 321 2205 2507 njll. |

| Okujwayelekile | I-DIN 1025 / EN 10034, GBT11263-2017 |

| Ubuso | Okukhandiwe, Kukhanya, Kupholishiwe, Kuphendukile Kahle, NO.4 Qeda, Math Qeda |

| Uhlobo | Imishayo ye-HI |

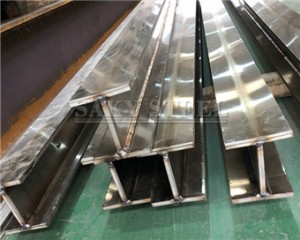

| Ubuchwepheshe | Okushisiwe Okushisiwe, Okushiselwe |

| Ubude | 6000, 6100 mm, 12000, 12100 mm nobude obudingekayo |

| Isitifiketi Sokuhlolwa Kwemishini | En 10204 3.1 noma En 10204 3.2 |

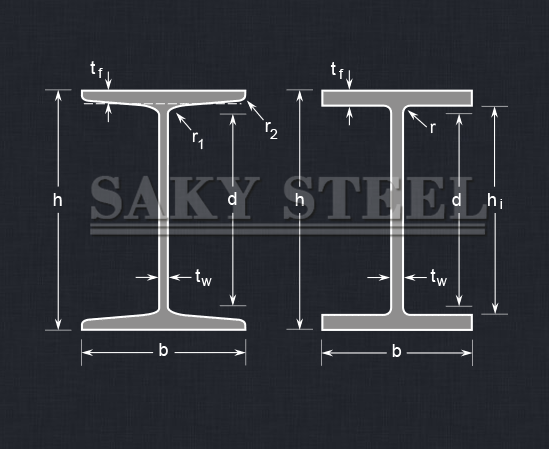

Uchungechunge lwe-I Beams kanye ne-S Beams luqukethe inqwaba yezinto zesakhiwo ezimise okwebha ezisetshenziswa ekwakhiweni nasembonini. Imishayo egoqelwe ngokushisayo ihlanganisa ama-conical flange, kuyilapho ama-laser-fused flange anama-flange ahambisanayo. Zombili lezi zinhlobo zithobela izindinganiso zokubekezelelana ezibekwe yi-ASTM A 484, nenguqulo exutshwe nge-laser nayo inamathela ekucacisweni komkhiqizo okuvezwe ku-ASTM A1069.

Insimbi engagqwali ingahlanganiswa-ishiselwe noma ibhowudiwe-noma yenziwe ngokucubungula okushisayo-i-hot rolling noma i-extrusion. Izingxenye ezivundlile phezulu nangaphansi kwe-beam zibizwa ngokuthi ama-flange, kuyilapho ingxenye exhumayo eqondile yaziwa ngokuthi iwebhu.

Isisindo se-Stainless steel beam:

| Imodeli | Isisindo | Imodeli | Isisindo |

| 100*50*5*7 | 9.54 | 344*354*16*16 | 131 |

| 100*100*6*8 | 17.2 | 346*174*6*9 | 41.8 |

| 125*60*6*8 | 13.3 | 350*175*7*11 | 50 |

| 125*125*6.5*9 | 23.8 | 344*348*10*16 | 115 |

| 148*100*6*9 | 21.4 | 350*350*12*19 | 137 |

| 150*75*5*7 | 14.3 | 388*402*15*15 | 141 |

| 150*150*7*10 | 31.9 | 390*300*10*16 | 107 |

| 175*90*5*8 | 18.2 | 394*398*11*18 | 147 |

| 175*175*7.5*11 | 40.3 | 400*150*8*13 | 55.8 |

| 194*150*6*9 | 31.2 | 396*199*7*11 | 56.7 |

| 198*99*4.5*7 | 18.5 | 400*200*8*13 | 66 |

| 200*100*5.5*8 | 21.7 | 400*400*13*21 | 172 |

| 200*200*8*12 | 50.5 | 400*408*21*21 | 197 |

| 200*204*12*12 | 72.28 | 414*405*18*28 | 233 |

| 244*175*7*11 | 44.1 | 440*300*11*18 | 124 |

| 244*252*11*11 | 64.4 | 446*199*7*11 | 66.7 |

| 248*124*5*8 | 25.8 | 450*200*9-14 | 76.5 |

| 250*125*6*9 | 29.7 | 482*300*11*15 | 115 |

| 250*250*9*14 | 72.4 | 488*300*11*18 | 129 |

| 250*255*14*14 | 82.2 | 496*199*9*14 | 79.5 |

| 294*200*8*12 | 57.3 | 500*200*10*16 | 89.6 |

| 300*150*6.5*9 | 37.3 | 582*300*12*17 | 137 |

| 294*302*12*12 | 85 | 588*300*12*20 | 151 |

| 300*300*10*15 | 94.5 | 596*199*10*15 | 95.1 |

| 300*305*15*15 | 106 | 600*200*11*17 | 106 |

| 338*351*13*13 | 106 | 700*300*13*24 | 185 |

| 340*250*9*14 | 79.7 |

Izicelo ze-Stainless Steel I Beams:

1.Ukwakhiwa Nengqalasizinda:

Imishayo yensimbi engagqwali isetshenziswa kakhulu ekwakhiweni kwezakhiwo, amabhuloho, neminye imisebenzi emikhulu yengqalasizinda.

2.Imishini Yezimboni:

Le mishayo ibalulekile ekwakhiweni kwemishini, ihlinzeka ngosekelo olubalulekile lwemishini esindayo yezimboni nezinqubo zokukhiqiza.

3.I-Marine and Coastal Engineering:

Imishayo yensimbi engagqwali ivame ukusetshenziswa ezindaweni zasolwandle ngenxa yokumelana kwayo okuhle nokugqwala kwamanzi anosawoti.

4.Amandla Avuselelekayo:

Imishayo yensimbi engagqwali isetshenziswa ekwakhiweni kwezinjini zomoya, amafreyimu ephaneli yelanga, nezinye izinhlelo zamandla avuselelekayo.

5.Ezokuthutha:

Imishayo yensimbi engagqwali idlala indima ebalulekile ekwakhiweni kwamabhuloho, amahubhe, kanye nezindawo ezidlula ngaphezulu kwingqalasizinda yezokuthutha.

6.Ukucubungula Amakhemikhali Nokudla:

Ukumelana kwensimbi engagqwali kumakhemikhali nezimo ezimbi kakhulu kwenza le mishayo ilungele ukusetshenziswa ezimbonini ezifana nokucubungula amakhemikhali, ukukhiqiza ukudla, kanye nemithi.

Izici Nezinzuzo:

1.Isondlo Esiphansi:

Ngenxa yokumelana nokugqwala nokugqwala, imishayo yensimbi engagqwali I idinga ukulungiswa okuncane, ukwehlisa izindleko zokuyilungisa zesikhathi eside uma kuqhathaniswa nezinye izinto ezifana ne-carbon steel.

2.Ukusimama:

Insimbi engagqwali yenziwe ngezinsalela ezigaywe kabusha futhi ingagaywa kabusha ngokugcwele ekupheleni komjikelezo wayo wokuphila. Lokhu kunciphisa umthelela wendawo futhi kusiza ukulondoloza imithombo yemvelo.

3.Ukuguquguquka komklamo:

Imishayo yensimbi engagqwali iguquguquka kakhulu, itholakala ngezimo ezihlukahlukene, osayizi, namabanga ukuze ihlangabezane nezimfuneko ezithile zanoma iyiphi iphrojekthi, kungaba okokwakha, imboni, noma ezokuthutha.

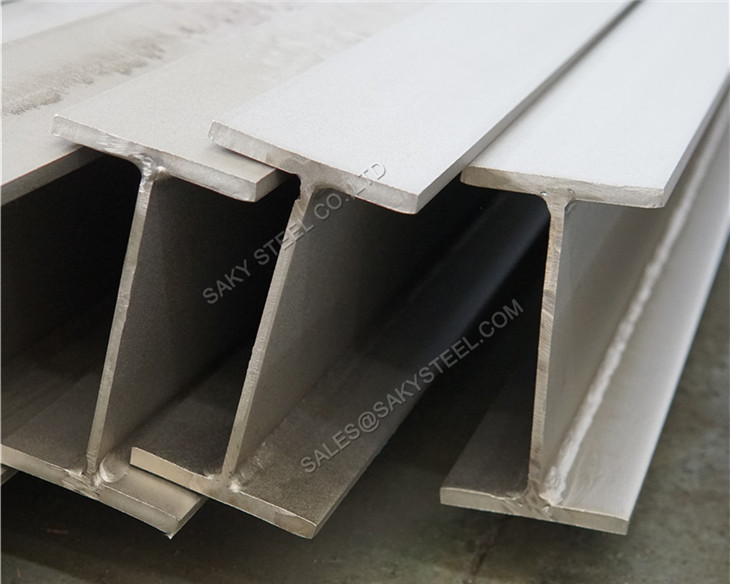

4.Ivelu yobuhle:

Ngendawo yayo ebushelelezi, epholishiwe, imishayo yensimbi engagqwali yengeza ukubukeka okubukekayo emiklamo yezakhiwo, okuyenza idume ezintweni zesakhiwo eziveziwe ezakhiweni zesimanjemanje.

5.Ukumelana Nokushisa Nomlilo:

Insimbi engagqwali iyakwazi ukumelana namazinga okushisa aphezulu ngaphandle kokulahlekelwa ubuqotho bayo besakhiwo, iyenze ifanelekele ukusetshenziswa kwezinga lokushisa eliphezulu njengeziko lezimboni, ama-reactors, nezakhiwo ezikwazi ukumelana nomlilo.

6.Ukwakha Okusheshayo Nokuphumelelayo:

Imishayo yensimbi engagqwali ingenziwa yakhiwe ngaphambili, okusheshisa inqubo yokwakha. Lokhu kusebenza kahle kuholela ezikhathini zokuphothulwa ngokushesha kwephrojekthi nokongiwa kwezindleko emsebenzini nasekusetshenzisweni kwempahla.

7.Inani Lesikhathi Eside:

Nakuba imishayo yensimbi engagqwali ingase ibe nezindleko eziphakeme zokuqala kunezinye izinto zokwakha, ukuqina kwayo, ukunakekelwa okuphansi, nempilo ende yesevisi inikeza imbuyiselo enkulu ekutshalweni kwezimali esikhathini eside.

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS, TUV, BV 3.2.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

Ukupakisha kwe-Stainless Steel I Beam:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho izimpahla zidlula eziteshini ezihlukahlukene ukuze zifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakishwa.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,