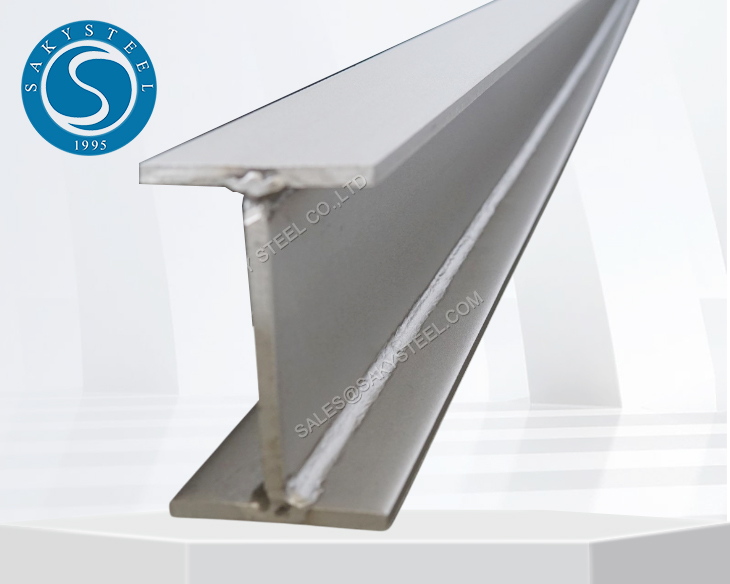

Intsimbi engatyiwayo I Beam

Inkcazelo emfutshane:

Jonga i-premium Stainless Steel I Beams e-SakySteel. Iphelele kulwakhiwo, izicelo zoshishino, kunye nokunye.

Intsimbi EngenaStainless I Beam:

I-Stainless Steel I-Beam iyinxalenye yolwakhiwo oluphezulu olusetyenziswa ngokuqhelekileyo kulwakhiwo kunye nezicelo zoshishino. Yenziwe ngentsimbi engapheliyo, inika ukuchasana okuphezulu kwi-corrosion, iqinisekisa ukusebenza okuhlala ixesha elide nakwiindawo ezinzima. Ngomlinganiselo wayo ofanelekileyo wobunzima bobunzima, ilungele ukuxhasa imithwalo enzima kwiibhulorho, izakhiwo kunye noomatshini. Ifumaneka ngobukhulu obuhlukeneyo kunye namabakala, i-Stainless Steel I-Beams i-customizable ukuhlangabezana neemfuno ezithile zayo nayiphi na iprojekthi, ukubonelela ngenkxaso yesakhiwo esithembekileyo nesisebenzayo.

Iinkcukacha ze-I-beam:

| IBanga | 302 304 304L 310 316 316L 321 2205 2507 njl. |

| Umgangatho | DIN 1025 / EN 10034, GBT11263-2017 |

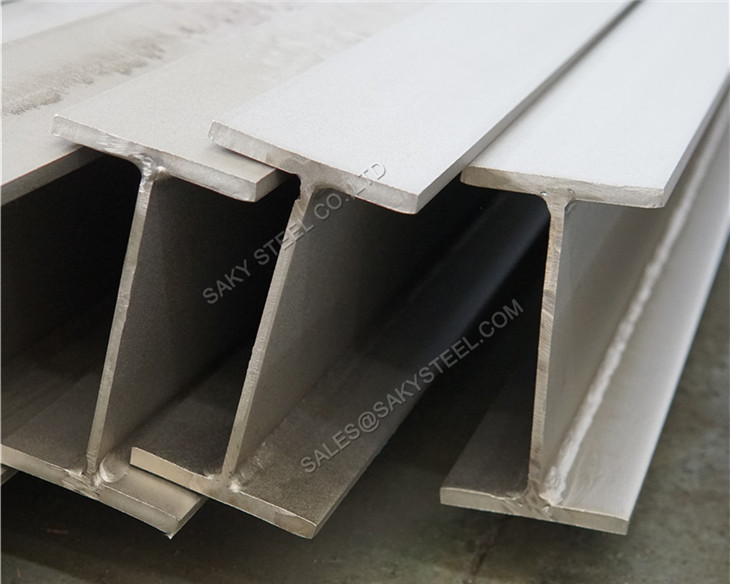

| Umphezulu | I-Pickled, Ikhazimle, Ikhazimlisiwe, iRhwaqekile iJikile, NO.4 Gqiba, Gqiba iMat |

| Uhlobo | HI Imiqadi |

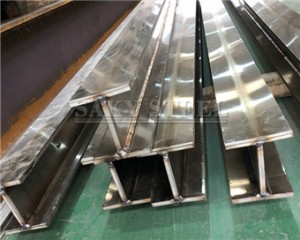

| Iteknoloji | I-Hot Rolled, i-Welded |

| Ubude | 6000, 6100 mm, 12000, 12100 mm & noBude obufunekayo |

| Mill Test Certificate | En 10204 3.1 okanye En 10204 3.2 |

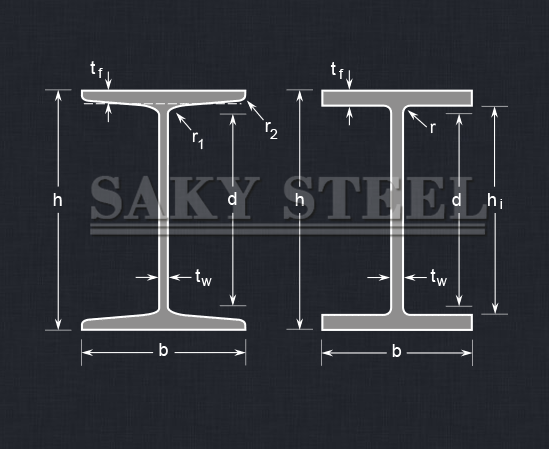

Uluhlu lwe-I Beams kunye ne-S Beams lubandakanya uluhlu olubanzi lwezinto ezibunjiweyo ze-bar ezisetyenziselwa ukwakhiwa kunye noshishino. Imiqadi eqengqelekayo eshushu ifaka iiflange eziphothiweyo, ngelixa imiqadi edityanisiweyo ngelaser ineeflange ezinxuseneyo. Zombini ezi ntlobo zihambelana nemigangatho yokunyamezela ebekwe yi-ASTM A 484, kunye ne-laser-fused version iphinda ibambelele kwiinkcukacha zemveliso ezichazwe kwi-ASTM A1069.

Intsimbi yensimbi engenasici inokuthi idityaniswe-i-welded okanye i-bolted-okanye yenziwe nge-hot processing-hot rolling okanye i-extrusion. Iziqendu ezithe tyaba kumphezulu naphantsi komqadi zibizwa ngokuba ziiflange, ngelixa ukudibanisa okuthe nkqo kubizwa ngokuba yiwebhu.

Ubunzima bentsimbi yentsimbi:

| Umzekelo | Ubunzima | Umzekelo | Ubunzima |

| 100*50*5*7 | 9.54 | 344*354*16*16 | 131 |

| 100*100*6*8 | 17.2 | 346*174*6*9 | 41.8 |

| 125*60*6*8 | 13.3 | 350*175*7*11 | 50 |

| 125*125*6.5*9 | 23.8 | 344*348*10*16 | 115 |

| 148*100*6*9 | 21.4 | 350*350*12*19 | 137 |

| 150*75*5*7 | 14.3 | 388*402*15*15 | 141 |

| 150*150*7*10 | 31.9 | 390*300*10*16 | 107 |

| 175*90*5*8 | 18.2 | 394*398*11*18 | 147 |

| 175*175*7.5*11 | 40.3 | 400*150*8*13 | 55.8 |

| 194*150*6*9 | 31.2 | 396*199*7*11 | 56.7 |

| 198*99*4.5*7 | 18.5 | 400*200*8*13 | 66 |

| 200*100*5.5*8 | 21.7 | 400*400*13*21 | 172 |

| 200*200*8*12 | 50.5 | 400*408*21*21 | 197 |

| 200*204*12*12 | 72.28 | 414*405*18*28 | 233 |

| 244*175*7*11 | 44.1 | 440*300*11*18 | 124 |

| 244*252*11*11 | 64.4 | 446*199*7*11 | 66.7 |

| 248*124*5*8 | 25.8 | 450 * 200 * 9-14 | 76.5 |

| 250*125*6*9 | 29.7 | 482*300*11*15 | 115 |

| 250*250*9*14 | 72.4 | 488*300*11*18 | 129 |

| 250*255*14*14 | 82.2 | 496*199*9*14 | 79.5 |

| 294*200*8*12 | 57.3 | 500*200*10*16 | 89.6 |

| 300*150*6.5*9 | 37.3 | 582*300*12*17 | 137 |

| 294*302*12*12 | 85 | 588*300*12*20 | 151 |

| 300*300*10*15 | 94.5 | 596*199*10*15 | 95.1 |

| 300*305*15*15 | 106 | 600*200*11*17 | 106 |

| 338*351*13*13 | 106 | 700*300*13*24 | 185 |

| 340*250*9*14 | 79.7 |

Usetyenziso lweMiqadi yeNsimbi eNgatyiwayo:

1.Ulwakhiwo kunye neZiseko zoPhuhliso:

Imiqadi yensimbi engenasici isetyenziswa ngokubanzi ekwakhiweni kwezakhiwo, iibhulorho, kunye nezinye iiprojekthi ezinkulu zeziseko ezingundoqo.

2. oomatshini boShishino:

Le miqadi ibalulekile kuyilo loomatshini, ibonelela ngenkxaso yolwakhiwo oluyimfuneko lwezixhobo zoshishino ezinzima kunye neenkqubo zokuvelisa.

3.Ubunjineli baseLwandle noNxweme:

Imiqadi yentsimbi ye-stainless I isetyenziswa ngokuqhelekileyo kwiindawo zaselwandle ngenxa yokuxhathisa kwayo ngokugqwesileyo kwi-corrosion yamanzi etyuwa.

4.Amandla ahlaziyekayo:

Imiqadi yentsimbi estainless isetyenziswa kulwakhiwo lweeinjini zomoya, iifreyimu zephaneli yelanga, kunye nezinye iinkqubo zamandla ahlaziyekayo.

5.Ezothutho:

Imiqadi yensimbi engenastainless idlala indima ephambili ekwakhiweni kweebhulorho, iitonela, kunye neendlela ezingaphezulu kwiziseko zothutho.

6.Ukwenziwa kweMichiza kunye noKutya:

Ukuxhathisa kwentsimbi engatyiwa kwiikhemikhali kunye neemeko ezigqithisileyo kwenza le miqadi ilungele ukusetyenziswa kumashishini afana nokulungisa imichiza, ukwenziwa kokutya, kunye namayeza.

Iimpawu kunye neeNzuzo:

1.Ugcino oluphantsi:

Ngenxa yokumelana nokugqwala kunye ne-corrosion, i-stainless steel I beams ifuna ukulungiswa okuncinci, ukunciphisa iindleko zokugcinwa kwexesha elide xa kuthelekiswa nezinye izinto ezifana ne-carbon steel.

2.Uzinzo:

Intsimbi estainless yenziwe ngenkunkuma esetyenzisiweyo kwaye inokuphinda isetyenziswe ngokupheleleyo ekupheleni kobomi bayo. Oku kunciphisa impembelelo yokusingqongileyo kwaye kunceda ukulondoloza ubutyebi bendalo.

3.Uyilo lokuguquguquka:

Imiqadi yensimbi engenastainless I iyaguquguquka kakhulu, ifumaneka kwiimilo ezahlukeneyo, ubungakanani, kunye namabakala ukuhlangabezana neemfuno ezithile zayo nayiphi na iprojekthi, nokuba kulwakhiwo, kushishino, okanye kwezothutho.

4.Ixabiso lobuhle:

Ngomphezulu ogudileyo, okhazimlisiweyo, imiqadi yentsimbi engatyiwayo yongeza inkangeleko ethandekayo kuyilo lwezakhiwo, izenza zidume kwizinto eziveziweyo zesakhiwo kwizakhiwo zale mihla.

5.Ukumelana nobushushu kunye nomlilo:

Insimbi engenasici iyakwazi ukumelana nobushushu obuphezulu ngaphandle kokulahlekelwa yintembeko yesakhiwo, iyenza ifaneleke kwizicelo zobushushu obuphezulu ezifana neziko zoshishino, i-reactors, kunye nezakhiwo ezinokumelana nomlilo.

6.Ulwakhiwo olukhawulezayo nolusebenzayo:

Imiqadi yensimbi engenasici inokuthi yenziwe ngaphambili, ekhawulezisa inkqubo yokwakha. Oku kusebenza kakuhle kubangela amaxesha okugqitywa kweprojekthi ngokukhawuleza kunye nokongiwa kweendleko kumsebenzi kunye nokusetyenziswa kwempahla.

7.Ixabiso Lexesha elide:

Nangona imiqadi yensimbi engenasici inokuba neendleko eziphezulu zokuqala kunezinye izinto, ukuqina kwazo, ukugcinwa okuphantsi, kunye nobomi benkonzo ende kunika imbuyekezo enkulu kutyalo-mali kwixesha elide.

Kutheni Khetha thina?

•Unokufumana izinto ezigqibeleleyo ngokwemfuno yakho ngexabiso elincinci elinokwenzeka.

•Sikwabonelela ngeeReworks, FOB, CFR, CIF, kunye namaxabiso okuhambisa umnyango ukuya emnyango. Sicebisa ukuba wenze isivumelwano sokuthumela ngenqanawe okuya kuba nokonga kakhulu.

•Iimathiriyeli esizibonelelayo ziqinisekiswa ngokupheleleyo, ukusuka kwisatifikethi sovavanyo lwemathiriyeli ekrwada ukuya kwisiteyitimenti somgangatho wokugqibela.(Iingxelo ziya kubonisa ngokwemfuneko)

•Siqinisekisa ukunika impendulo kwiiyure ezingama-24(ngokuqhelekileyo ngeyure enye)

•Ukubonelela nge-SGS, TUV, BV 3.2 ingxelo.

•Sizinikele ngokupheleleyo kubathengi bethu. Ukuba akunakwenzeka ukuhlangabezana neemfuno zakho emva kokuvavanya zonke iinketho, asiyi kukukhohlisa ngokwenza izithembiso zobuxoki eziza kudala ubudlelwane obuhle kubathengi.

•Ukubonelela ngenkonzo yokumisa enye.

I-Stainless Steel I Beam Packing:

1. Ukupakisha kubaluleke kakhulu ngokukodwa kwimeko yokuthunyelwa kwamanye amazwe apho umthwalo udlula kwiitshaneli ezahlukeneyo ukuya kufika kwindawo yokugqibela, ngoko ke sibeka inkxalabo ekhethekileyo malunga nokupakishwa.

2. I-Saky Steel ipakisha iimpahla zethu ngeendlela ezininzi ezisekelwe kwiimveliso. Sipakisha iimveliso zethu ngeendlela ezininzi, ezinje,