AISI 431 Stainless Steel Forged Block |1.4057 High Strength Machinable Steel

Tlhaloso e Khutšoanyane:

431 Stainless Steel Forged Blocks ke litšepe tse matla tse phahameng tsa martensitic tse tsejoang ka thepa ea tsona e ntle ea mochini, ho hanyetsa kutu e ntle, le ho thatafala ho hoholo. Li-blocks tsena tse qhekelitsoeng hangata li sebelisoa ho etsa likarolo tse hlokang matla le ho thibela kutu e itekanetseng, joalo ka li-shafts, hlobo, lisebelisoa tsa sefofane, likarolo tsa pompo le lisebelisoa tsa metsing.

AISI 431 Forged Steel Block:

AISI 431 Forged Steel Blockke sehlahisoa sa tšepe ea martensitic se nang le matla a phahameng, se sa bolaeeng ke kutu, se sebelisoang haholo lits'ebetsong tse hlokang ts'ebetso e ntle haholo ea mochini le ho hanyetsa kutu ka mokhoa o itekanetseng. Ka litaba tse phahameng tsa chromium le nickel, 431 e fana ka boima bo ntlafetseng, ho thatafala, le ho hanyetsa ho fokotseha ha ho bapisoa le litekanyetso tse tloaelehileng tsa martensitic tse kang 410 kapa 420. Li-blocks tsena tse entsoeng ka mokhoa o tloaelehileng li fanoa ka maemo a annealed kapa quenched and tempered (QT) 'me li ka ntlafatsoa ho ea ka mekhoa e fokolang. E loketse li-shafts, likarolo tsa pompo, 'mele ea li-valve le lisebelisoa tsa lisebelisoa, li-block tsa AISI 431 ke khetho e ntle bakeng sa liindasteri tse kang sefofane, marine, ts'ebetso ea lik'hemik'hale le boenjiniere bo akaretsang.

Litlhaloso tsa 431 SS Forged Block:

| Kereiti | 410, 416, 420, 430, 431, joalo-joalo. |

| Litlhaloso | ASTM A276 |

| Boholo | Customizable |

| E felile | Surface Milling |

| Mofuta | Li-blocks |

431 Block Forged Limaraka tse lekanang:

| Standard | UNS | EN | JIS |

| 431 | S43100 | 1.4057 | SUS 431 |

Sebopeho sa 431 SS Forged Bar Chemical:

| Kereiti | C | Si | Mn | S | P | Cr | Ni |

| 431 | 0.12-0.20 | 1.0 | 1.0 | 0.030 | 0.040 | 15.0-17.0 | 1.25-2,5 |

431 Stainless Machining Block Heat Treatment

Li-block tsa machining tsa tšepe tse 431 hangata li ts'oaroa ka mocheso ho fihlela thepa e nepahetseng ea mochini. Maemo a tloaelehileng haholo ke Quenched and Tempered (QT) le H1150. Kalafo ea mocheso e ntlafatsa matla a block, ho tiea le ho hanyetsa ho bola, ho e etsa hore e tšoanelehe bakeng sa ho sebetsa ka mokhoa o nepahetseng oa mochini le lits'ebetso tse phahameng haholo. Sebaka se seng le se seng se sebetsoa ho netefatsa ho ts'oana ha sebopeho, botsitso ba sebopeho, le boima bo sa fetoheng ka hohle.

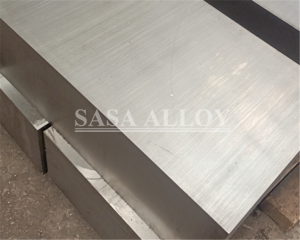

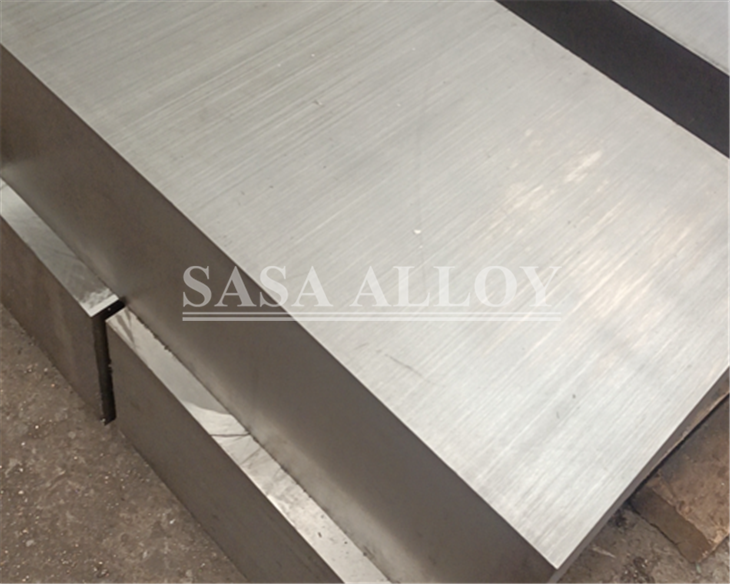

1.4057 Forged Block Surface Milling Finish

1.4057 Forged Stainless Steel Block, eo hape e tsejoang e le AISI 431, ke tšepe e sa hloekang ea martensitic e matla haholo e nang le thepa e ntle haholo ea mochini le ho hanyetsa kutu ka mokhoa o itekanetseng. E fanoe ka boemo bo entsoeng ka mokhoa oa ho sila ka holim'a metsi, thibela e fana ka ho nepahala ho ntlafetseng le sebaka se boreleli, se etsa hore e be se loketseng bakeng sa mochine o tlaase oa CNC kapa ho etsoa ka mokhoa o nepahetseng.

Teko ea roughness ea 431 square bar

Libaka tsa rona tsa lisekoere tsa tšepe tse 431 li ntse li hlahlojoa ka thata holim'a metsi ho netefatsa hore li fihlela litlhoko tse nepahetseng tsa lits'ebetso tsa indasteri tse sebetsang hantle. Re sebelisa li-calibrated surface profilometers, re lekanya boleng ba Ra (Roughness Average) ho latela maemo a machaba a kang ISO 4287 le ASME B46.1. Teko ena e etsa bonnete ba hore sebaka sa marang-rang se loketse ts'ebeliso ea bohlokoa indastering ea boenjineri ba sepakapaka, sa metsing le sa metjhini. Ka ho hanyetsa kutu e ntle haholo le matla a phahameng a tsitsipano, tšepe e sa hloekang ea 431 e loketse likarolo tse hlokang ho tšoarella le ho nepahala ha boholo. Teko e thata e netefatsa boitokisetso ba mochini mme e matlafatsa ts'epahalo ea sehlahisoa lits'ebetsong tse sebelisoang qetellong.

Phallo ea Tlhahiso ea 431 Forged Block

Ona ke mokhoa o tloaelehileng oa tlhahiso bakeng sa li-block tsa rona tse 431 tse entsoeng ka tšepe:

1. Ingot → 2. Forging after heat → 3. Cutting → 4. Heat Treatment → 5. Surface Milling Finish → 6. Finished Product

Sebaka se seng le se seng se qala ka ingot ea boleng bo phahameng, e futhumetseng le e chesang e chesang ho ntlafatsa sebopeho sa eona sa ka hare. Ka mor'a ho khaola ka boholo, thibela e fumana phekolo ea mocheso ho finyella boima le boima bo lakatsehang. Ka mor'a moo, ho sebelisoa leloala ho netefatsa ho bata le ho nepahala pele ho tlhahlobo ea ho qetela le ho fana ka thepa.

Litšebeletso tsa Rōna

1.Custom Forging - Li-blocks tse ferekaneng li fumaneha ka litekanyo le libopeho tse lokiselitsoeng.

2.Kalafo ea Mocheso - Ho tima & ho halefa (QT), ho tlosoa, kapa boemo ba H1150 bo thehiloeng ho kopo.

3.Surface Milling - Ho sila ka holimo ka mokhoa o nepahetseng ka holimo ho netefatsa ho bata le ho fokotsa nako ea machining.

4.CNC Machining (ka kopo) - Mechine e thata kapa e felileng e fumaneha.

5.Tlhahlobo ea Mokha oa Boraro - Tšehetso bakeng sa SGS, BV, TUV, kapa tlhahlobo e khethiloeng ke bareki.

Setifikeiti sa Teko sa 6.Mill (EN 10204 3.1/3.2) - Ho lateloa ka ho feletseng le ho lumellana le litekanyetso tsa machaba.

7.Flexible Packaging & Export Logistics - Li-pallets tsa lehong, mekotla e entsoeng ka tšepe, liphutheloana tse loketseng leoatle.

8.Fast Lead Time & Global Shipping - Kemiso e ka tšeptjoang ea tlhahiso le likhetho tsa ho fana ka lefats'e ka bophara.

9.Technical Support - Khetho ea thepa, likhothaletso tsa machining, le tlhahlobo ea ho taka.

431 Stainless Block Packaging Pre-Hardened Block Packaging:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,