AISI 431 Stainless Steel Forged Block |1.4057 High Strength Machinable Steel

Short Description:

431 Stainless Steel Forged Blocks are high-strength martensitic stainless steels known for their excellent mechanical properties, good corrosion resistance, and superior hardness. These forged blocks are commonly used in manufacturing components that require both strength and moderate corrosion resistance, such as shafts, molds, aerospace fixtures, pump parts, and marine hardware.

AISI 431 Forged Steel Block:

AISI 431 Forged Steel Block is a high-strength, corrosion-resistant martensitic stainless steel product, widely used in applications requiring excellent mechanical performance and moderate corrosion resistance. With a high content of chromium and nickel, 431 offers improved toughness, hardenability, and resistance to scaling compared to standard martensitic grades like 410 or 420.These forged blocks are typically supplied in annealed or quenched and tempered (QT) conditions and can be further machined to customer-specified dimensions. Ideal for shafts, pump components, valve bodies, and tooling fixtures, AISI 431 forged blocks are an excellent choice for industries such as aerospace, marine, chemical processing, and general engineering.

Specifications of 431 SS Forged Block:

| Grade | 410, 416, 420, 430, 431,etc. |

| Specifications | ASTM A276 |

| Size | Customizable |

| Finished | Surface Milling |

| Type | Blocks |

431 Forged Block Equivalent grades:

| Standard | UNS | EN | JIS |

| 431 | S43100 | 1.4057 | SUS 431 |

431 SS Forged Bar Chemical Composition:

| Grade | C | Si | Mn | S | P | Cr | Ni |

| 431 | 0.12-0.20 | 1.0 | 1.0 | 0.030 | 0.040 | 15.0-17.0 | 1.25-2.5 |

431 Stainless Machining Block Heat Treatment

431 stainless steel machining blocks are typically heat treated to achieve optimal mechanical properties. The most common conditions are Quenched and Tempered (QT) and H1150. Heat treatment enhances the block’s strength, toughness, and corrosion resistance, making it suitable for precision machining and high-stress applications. Each block is processed to ensure structural uniformity, dimensional stability, and consistent hardness throughout.

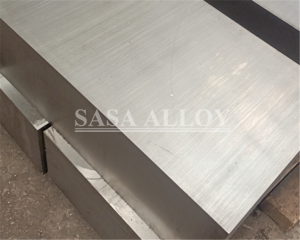

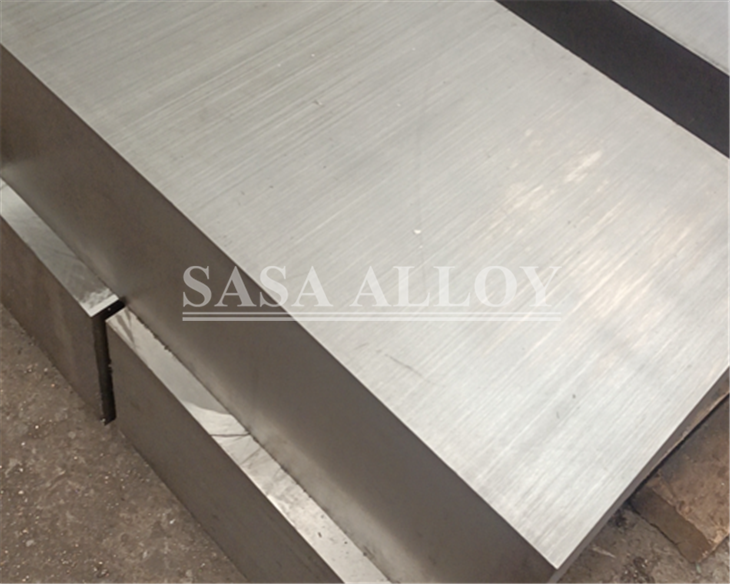

1.4057 Forged Block Surface Milling Finish

1.4057 Forged Stainless Steel Block, also known as AISI 431, is a high-strength martensitic stainless steel with excellent mechanical properties and moderate corrosion resistance. Supplied in forged condition with surface milling finish, the block offers improved dimensional accuracy and a smoother surface, making it ideal for downstream CNC machining or precision fabrication.The surface milling finish ensures reduced surface roughness (typically Ra ≤ 3.2 µm), allowing better fit, alignment, and reduced machining time in critical applications.

431 square bar Roughness test

Our 431 stainless steel square bars undergo strict surface roughness testing to ensure they meet the precise requirements of high-performance industrial applications. Using calibrated surface profilometers, we measure the Ra (Roughness Average) value in accordance with international standards such as ISO 4287 and ASME B46.1. This test ensures the bar surface finish is suitable for critical uses in aerospace, marine, and mechanical engineering industries.With excellent corrosion resistance and high tensile strength, 431 stainless steel is ideal for components requiring both durability and dimensional accuracy. The roughness test verifies machining readiness and enhances product reliability in end-use applications.

Production Flow of 431 Forged Block

This is the typical production process for our 431 stainless steel forged blocks:

1. Ingot → 2. Forging after heating → 3. Cutting → 4. Heat Treatment → 5. Surface Milling Finish → 6. Finished Product

Each block begins with a high-quality ingot, which is heated and hot-forged to refine its internal structure. After cutting to size, the block undergoes heat treatment to achieve the desired hardness and toughness. A surface milling finish is then applied to ensure flatness and precision before final inspection and delivery.

Our Services

1.Custom Forging – Forged blocks available in tailored dimensions and shapes.

2.Heat Treatment – Quenched & tempered (QT), annealed, or H1150 condition based on application.

3.Surface Milling – High-precision surface milling to ensure flatness and reduced machining time.

4.CNC Machining (on request) – Rough or semi-finished machining available.

5.Third-Party Inspection – Support for SGS, BV, TUV, or customer-nominated inspection.

6.Mill Test Certificate (EN 10204 3.1/3.2) – Full traceability and compliance with international standards.

7.Flexible Packaging & Export Logistics – Wooden pallets, steel-strapped bundles, seaworthy packaging.

8.Fast Lead Time & Global Shipping – Reliable production scheduling and worldwide delivery options.

9.Technical Support – Material selection, machining recommendations, and drawing review.

431 Stainless Pre-Hardened Block Packaging:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,