Stainless Steel Clean BA EP Tubes

Short Description:

Stainless Steel Clean BA EP Tubes with bright annealed or electropolished finish for high purity gas and fluid systems. Ideal for semiconductor, pharmaceutical and laboratory applications.

Clean tubes are characterized by a highly smooth inner surface, ultra-high purity, and tight dimensional tolerances. The internal surface roughness is strictly controlled, with an Ra value of ≤ 0.6 μm, ensuring excellent cleanliness and flow performance.

These tubes are widely used in industries with stringent hygiene and purity requirements, including semiconductor manufacturing, medical catheter production, food and beverage processing, pharmaceutical systems, superheater heat exchangers, and high-purity gas and fluid piping systems.

Manufactured in compliance with ASTM A269 / ASTM A270 standards, the tubes can be supplied with either a Bright Annealed (BA) or Electropolished (EP) inner surface finish. For applications requiring the highest level of cleanliness, the tubes are nitrogen purged and clean-room packaged, ensuring contamination-free delivery.

| Specifications of 316 BA EP Stainless Steel Pipe: |

| Specifications | ASTM A269,JIS3459 |

| Grade | 316L,1.4404,1.4435 |

| Type | Seamless pipe |

| Specification range | 3.175-325×0.5-20MM |

| Wall Thickness | 0.5 mm – 20 mm (custom thickness on request) |

| Length | Up to 6000 mm (custom lengths available) |

| Surface | Bright |

| Condition | Annealed / Hard / As Drawn |

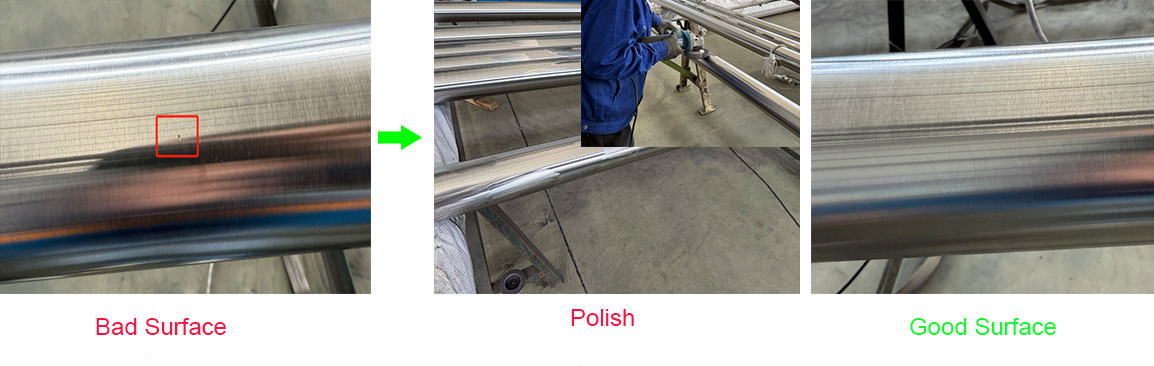

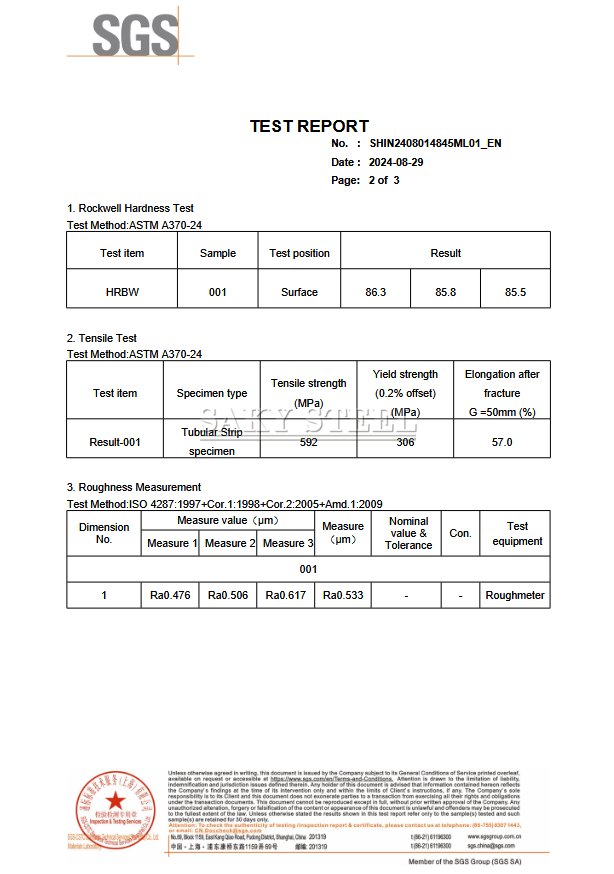

| Clean BA EP Stainless Steel Tubes Roughness Test : |

The inner surface roughness of the clean tubes is strictly inspected using calibrated surface roughness measuring instruments. Measurements are carried out along the tube’s longitudinal direction to ensure accurate and repeatable results. The Ra value of the inner surface is controlled to meet specified requirements, with typical roughness levels of Ra ≤ 0.6 μm for clean tubes. All inspection procedures are conducted in accordance with relevant international standards to guarantee consistent surface quality and cleanliness performance.

| Support for third-party sample testing : |

|

|

| Surface Finish: |

The clean tubes are available with Bright Annealed (BA) or Electropolished (EP) surface finishes.

-

Bright Annealed (BA):

The tubes are solution annealed in a controlled protective atmosphere, resulting in a bright, smooth and uniform inner surface. BA finish provides good corrosion resistance and low surface roughness, making it suitable for high-purity gas and fluid applications. -

Electropolished (EP):

The EP process further refines the inner surface through electrochemical polishing, significantly reducing surface roughness and removing embedded contaminants. This finish enhances corrosion resistance and minimizes particle adhesion, making it ideal for ultra-high cleanliness environments such as semiconductor and pharmaceutical systems.

| Key Features of Stainless Steel BA EP Tubing : |

-

Ultra-smooth inner surface with controlled roughness (Ra ≤ 0.6 μm)

-

High cleanliness and ultra-high purity, suitable for critical applications

-

Available with Bright Annealed (BA) or Electropolished (EP) surface finish

-

Excellent corrosion resistance and minimal particle generation

-

Tight dimensional tolerances for high-precision piping systems

-

Manufactured in accordance with ASTM A269 / A270 standards

-

Nitrogen purged and clean-room packaged for contamination-free delivery

| BA EP stainless steel tubing Applications: |

-

Semiconductor ultra-high purity (UHP) gas delivery systems

-

Pharmaceutical and biotechnology process piping

-

Medical devices and catheter manufacturing systems

-

Food and beverage processing and sanitary pipelines

-

Superheater and heat exchanger tubing

-

High-purity gas and fluid distribution systems

-

Laboratory and analytical instrumentation tubing

| Customer Visit : |

We recently welcomed an overseas customer to visit our facility. During the visit, the customer toured our production workshop, inspection laboratory, and finished product warehouse, gaining a comprehensive understanding of our clean stainless steel BA and EP tube manufacturing process, surface finishing techniques, and quality control system.

Both parties had in-depth discussions on product standards, surface roughness control, clean packaging, and application requirements. The customer expressed strong confidence in our manufacturing capability and quality assurance, and looks forward to establishing long-term cooperation.

| FAQ : |

Q1: What is the difference between BA and EP tubes?

BA tubes are bright annealed with smooth surfaces, while EP tubes are electropolished to achieve even lower surface roughness and higher cleanliness.

Q2: Which grade is best for clean BA EP tubes?

316L stainless steel is most commonly used due to its superior corrosion resistance and cleanliness performance.

Q3: How are clean tubes packaged?

Each tube is cleaned, dried, capped on both ends and packed in clean plastic with protective packaging.

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,