-

Tool steel is a special class of alloy steels that is specifically engineered for manufacturing tools, dies, and equipment used in cutting, shaping, and forming materials. Unlike regular carbon steels, tool steels contain carefully balanced amounts of alloying elements such as tungsten, molybdenu...Read more »

-

Stainless steel has become one of the most widely used materials across industries due to its corrosion resistance, durability, and versatility. However, not all stainless steel grades are created equal. While grades such as 304, 316L, and 317L are commonly used in industrial and commercial appli...Read more »

-

Stainless steel has long been a vital material in industries that demand durability, corrosion resistance, and strength. Among the many grades of stainless steel, 904L stainless steel stands out as a high-performance, low-carbon, austenitic alloy designed for extreme environments. With its high n...Read more »

-

The aviation industry relies on advanced engineering solutions to ensure safety, performance, and efficiency. One of the most critical components inside modern aircraft engines is the heat exchanger. These devices manage thermal energy by transferring heat between fluids, enabling engines to oper...Read more »

-

Stainless steel has become one of the most versatile and widely used materials across industries. From kitchen utensils to skyscrapers, and from chemical equipment to medical devices, stainless steel is everywhere. Among the many grades of stainless steel, Grade 304 has earned the reputation of b...Read more »

-

Food safety and hygiene are top priorities in the modern food industry. From processing raw materials to packaging finished products, every step demands equipment that is durable, corrosion resistant, and easy to clean. Among the wide range of stainless steel grades available, stainless steel 317...Read more »

-

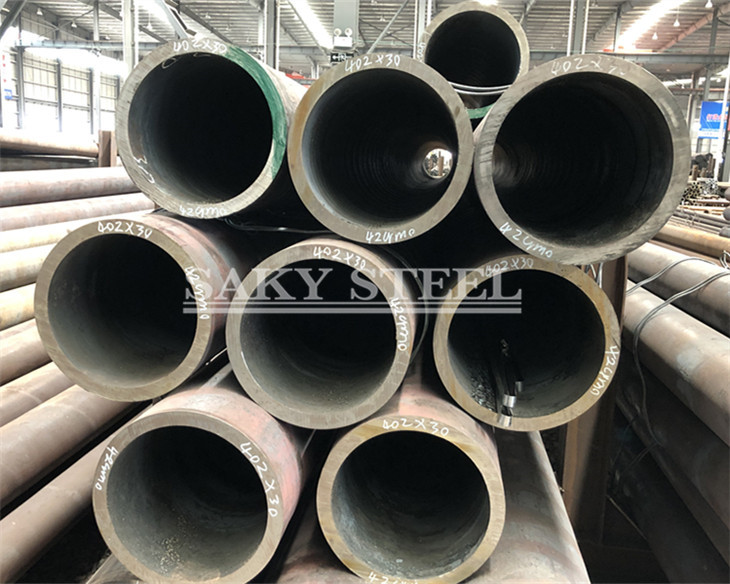

Pipes are the backbone of industrial infrastructure, connecting systems, transporting fluids, and supporting structural applications. Among the many types of metallic pipes available, carbon steel pipes and mild steel pipes are some of the most widely used. Known for their strength, durability, a...Read more »

-

Stainless steels are widely used in industries that demand durability, corrosion resistance, and strength at both low and high temperatures. Among the many grades available, 310 and 310S stainless steels stand out because of their remarkable performance in extreme heat and oxidizing environments....Read more »

-

Low carbon steel, also known as mild steel, is one of the most commonly used types of steel in the world. Its versatility, affordability, and wide range of applications make it an essential material in industries such as construction, automotive, manufacturing, and machinery. To better understand...Read more »

-

Shell and tube heat exchangers are among the most widely used types of heat exchangers in industries such as power generation, chemical processing, oil and gas, marine, and HVAC. Their versatility, efficiency, and ability to handle extreme conditions make them a preferred choice for engineers and...Read more »

-

Boiler tubes are a critical component in power generation, industrial heating systems, and chemical processing industries. They are specifically designed to withstand high pressure, extreme temperature, and corrosive environments. Understanding what boiler tubes are, their types, and how they are...Read more »

-

Stainless steel precision tubes are one of the most important products in modern engineering and manufacturing. Known for their dimensional accuracy, high strength, and superior surface finish, these tubes are widely used across industries such as automotive, aerospace, medical, petrochemical, an...Read more »

-

Carbon steel seamless pipes play an essential role in industries ranging from construction and mechanical engineering to oil, gas, and petrochemical applications. Selecting the right pipe is not just about price or availability, but about ensuring long-term performance, safety, and efficiency. Wi...Read more »

-

Hot rolled steel is one of the most widely used materials in manufacturing, construction, automotive, and heavy machinery. Known for its versatility, cost-effectiveness, and ease of fabrication, hot rolled steel comes in multiple grades, each designed for specific mechanical properties and perfor...Read more »

-

Rust is one of the most common problems that affect metal objects, tools, and structures. Caused by the chemical reaction between iron, oxygen, and moisture, rust weakens metal, affects its appearance, and can shorten its lifespan. Whether it’s a small spot on a household tool or widespread corro...Read more »