-

Forging is a powerful metal forming process that enhances the mechanical properties of components through deformation under pressure. Forged parts are stronger, more reliable, and longer-lasting than those produced by casting or machining alone. But to achieve high-quality forgings, it takes more...Read more »

-

In the forging industry, oxidation is one of the most common and costly challenges. Oxidation can degrade the surface quality of forged parts, reduce mechanical performance, and increase machining or finishing costs. Whether you are working with carbon steel, stainless steel, alloy steel, or tita...Read more »

-

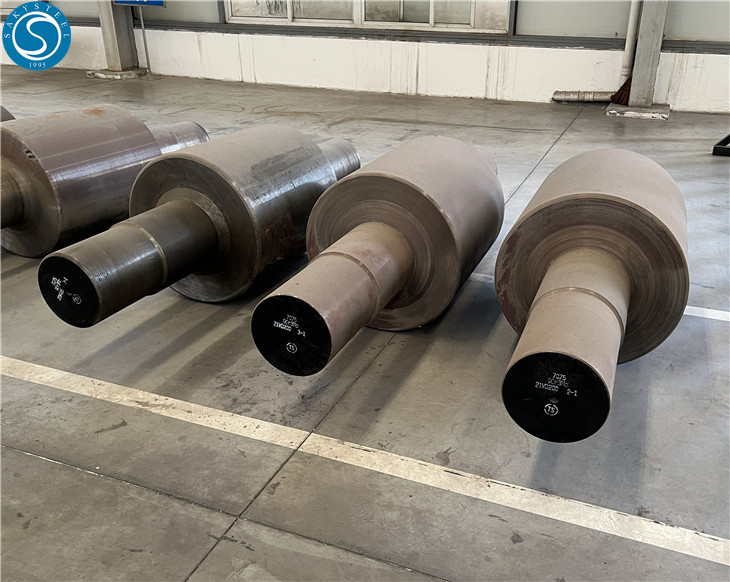

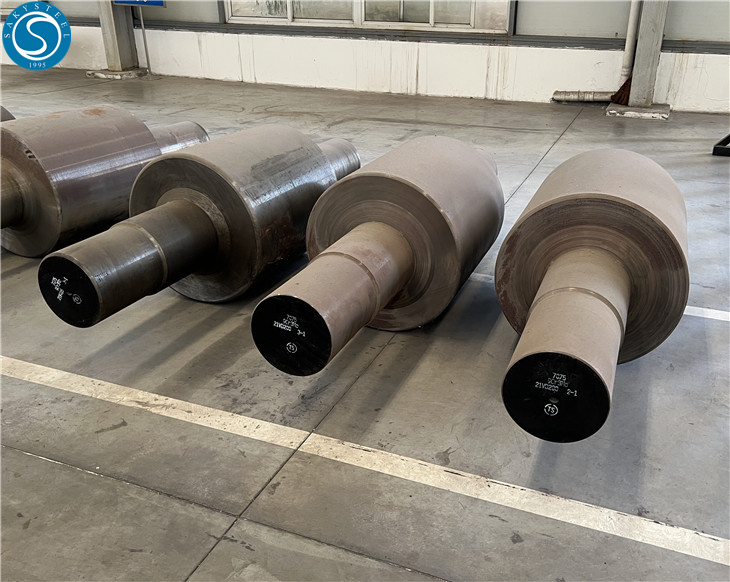

Shaft forgings are integral components used in rotating equipment and machinery across a wide range of industries, including energy, shipbuilding, aerospace, mining, and heavy machinery. These shafts transmit torque and rotational power under variable loads, speeds, and working conditions. One of...Read more »

-

Stainless steel forgings are widely used in critical applications across industries such as petrochemical, aerospace, power generation, food processing, and marine engineering. These components are known for their superior strength, corrosion resistance, and durability under extreme conditions. H...Read more »

-

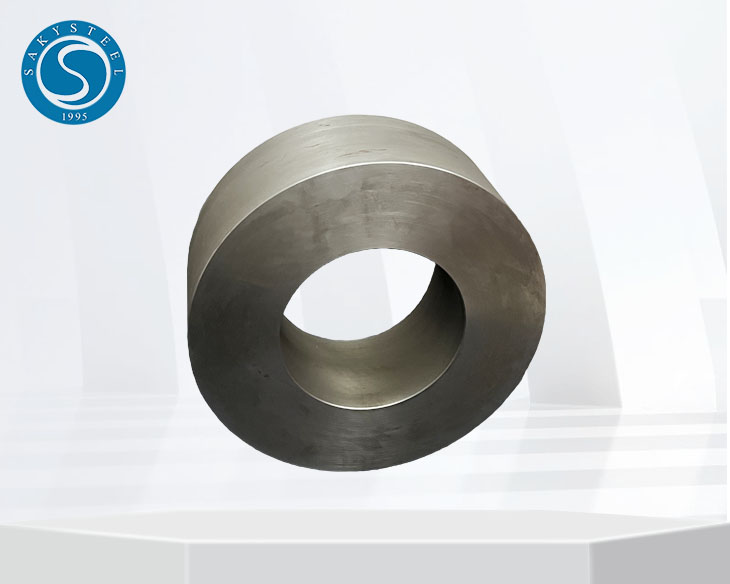

Forging is a critical manufacturing process used to produce high-strength, durable components such as shafts, gears, flanges, rods, and rings for industries like aerospace, automotive, energy, and petrochemicals. However, the performance and reliability of forged parts heavily depend on their qua...Read more »

-

Forging is one of the oldest and most reliable metal forming processes in the manufacturing world. It involves shaping metal using localized compressive force, usually delivered by a hammer, press, or die. Today, forgings are widely used in industries like aerospace, automotive, oil and gas, powe...Read more »

-

Forging is a widely used metalworking process that shapes metal using compressive force. It is essential in producing high-strength components such as flanges, shafts, gears, bars, and rings across industries like aerospace, automotive, oil and gas, and machinery manufacturing. Despite its benefi...Read more »

-

Tool steel is essential to the success of precision machining, metal stamping, die making, and a wide range of industrial applications. Among the many tool steel types available, A2 and D2 are two of the most commonly used. Engineers, procurement specialists, and tool designers often face the que...Read more »

-

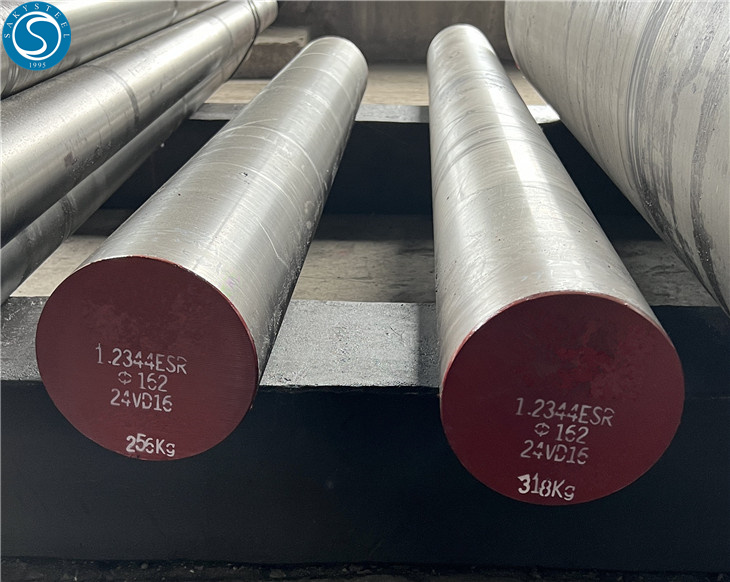

Tool steel is the backbone of countless industries, especially in mold making, die casting, hot forging, and extrusion tooling. Among the many grades available, 1.2343 tool steel is known for its excellent hot strength, toughness, and thermal fatigue resistance. However, in global trade and engin...Read more »

-

In the world of high-performance tooling materials, tool steels play a vital role in meeting demanding mechanical, thermal, and wear-resistance requirements. Among them, 1.2767 tool steel stands out as a premium-grade alloy used in heavy-duty applications. Known for its high hardness, excellent t...Read more »

-

Tool steels are crucial in the manufacturing and mold-making industries due to their excellent strength, hardness, and resistance to deformation at high temperatures. One widely used tool steel grade is 1.2311, which is known for its good polishability, machinability, and uniform hardness. For in...Read more »

-

Forging is a critical manufacturing process used to produce parts with high strength, excellent fatigue resistance, and structural reliability. However, not all forged components are created equal. Identifying the quality of forging is essential to ensure safety, performance, and compliance with ...Read more »

-

Forging and stamping are two major metal forming technologies that play a vital role in modern manufacturing. When combined or compared within industrial production, forging stamping processes bring out distinct technological characteristics that offer improved mechanical strength, cost-effective...Read more »

-

Forging is a critical metal forming process used to manufacture high-performance components for industries such as aerospace, automotive, oil and gas, energy, and machinery. The performance and reliability of forged parts heavily depend on the quality of the raw materials used. Any inconsistency ...Read more »

-

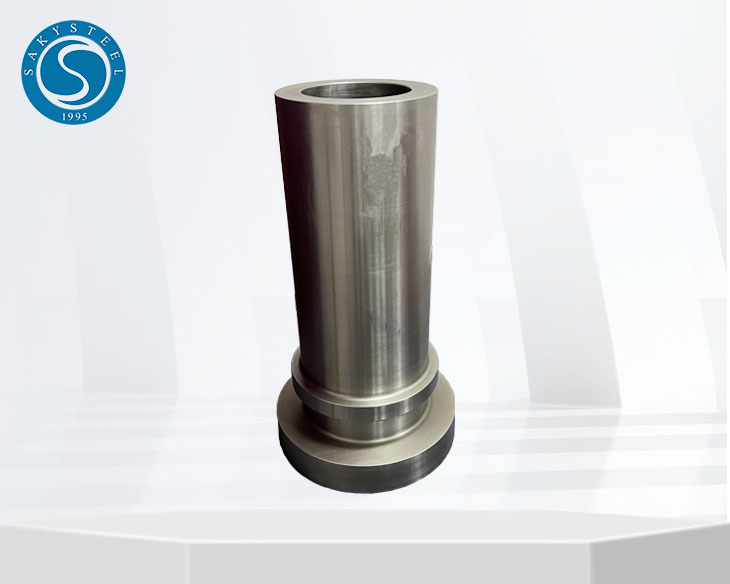

Forging is one of the oldest and most reliable metal forming processes used in modern industrial manufacturing. It involves shaping metal using localized compressive forces, typically delivered by hammering, pressing, or rolling. The products derived from forging are known for their superior mech...Read more »